9L-2 Paint / Coatings:

Plastic Parts Finishing

S5JB0A9C01002

Paintable plastic parts are ABS plastic parts.

Painting

Rigid or hand ABS plastic needs no primer coating.

General acrylic lacquers can be painted properly over

hard ABS plastic in terms of adherence.

1) Use cleaning solvent for paint finish to wash each

part.

2) Apply conventional acrylic color lacquer to part

surface.

3) Follow lacquer directions for required drying time.

(Proper drying temperature range is 60 – 70 °C (140

– 158 °F)).

Reference

Plastic parts employ not only ABS (Acrylonitrile

Butadiene Styrene) plastic but also polypropylene, vinyl,

or the like plastic. Burning test method to identify ABS

plastic is described below.

1) Use a sharp blade to cut off a plastic sliver from the

part at its hidden backside.

2) Hold sliver with pincers and set it on fire.

3) Carefully observe condition of the burning plastic.

4) ABS plastic must raise readily distinguishable back

smoke while burning with its residue suspended in

air temporarily.

5) Polypropylene must raise no readily distinguishable

smoke while burning.

Component Location

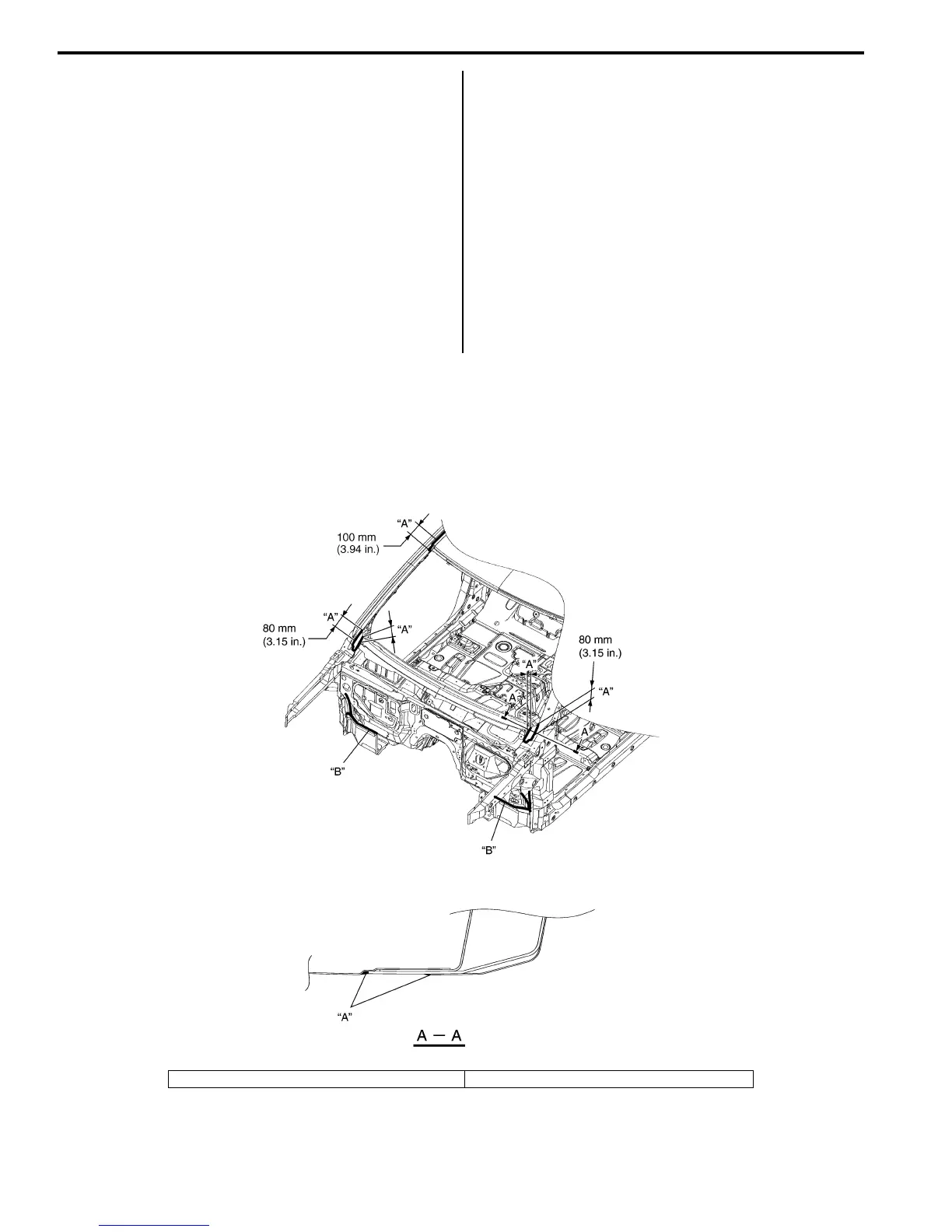

Sealant Application Areas

S5JB0A9C03001

Front Structure Panel

I5JB0A9C0001-03

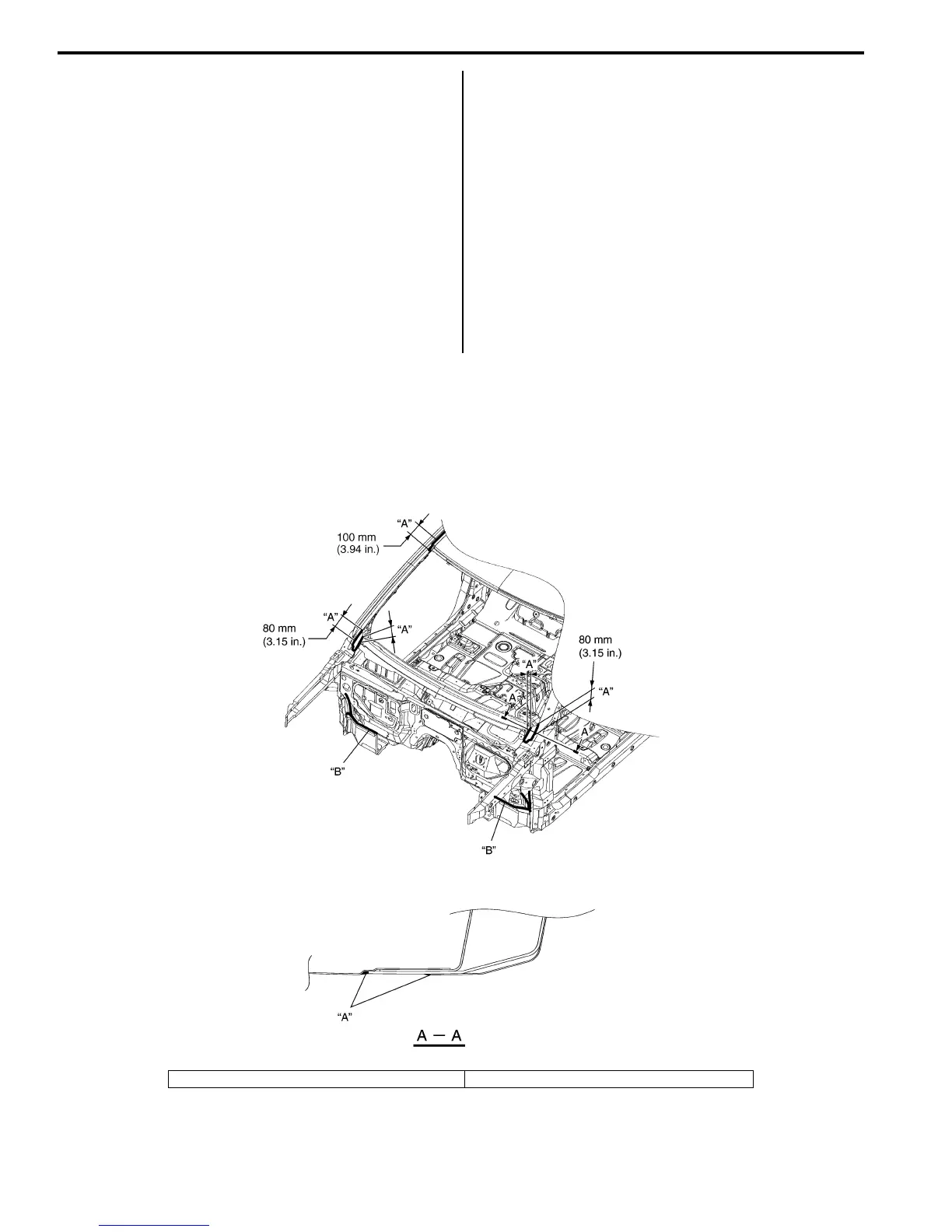

“A”: Flatten sealant. “B”: Smooth out sealant with a brush.

Loading...

Loading...