Brake Control System and Diagnosis: 4A-10

Flushing Brake Hydraulic System

S5JB0A4106009

It is recommended that entire hydraulic system be

thoroughly flushed with clean brake fluid whenever new

parts are installed in hydraulic system.

Periodical change of brake fluid is also recommended.

Booster Operation Check

S5JB0A4106010

There are two ways to perform this inspection, with and

without a tester. Ordinarily, it is possible to roughly

determine its condition without using a tester.

NOTE

For this check, make sure that no air is in

hydraulic line.

Inspection without Tester

Check air tightness

1) Start engine.

2) Stop engine after running for 1 to 2 minutes.

3) Depress brake pedal several times with the same

load as in ordinary braking and observe pedal travel.

If pedal goes down deep the first time but its travel

decreases as it is depressed the second and more

times, air tightness is obtained.

4) If pedal travel doesn’t change, air tightness isn’t

obtained.

NOTE

If defective, inspect vacuum lines and sealing

parts, and replace any faulty part.

When this has been done, repeat the entire

test.

Check operation

1) With engine stopped, depress brake pedal several

times with the same load and make sure that pedal

travel doesn’t change.

2) Start engine while depressing brake pedal. If pedal

travel increases a little, operation is satisfactory. But

no change in pedal travel indicates malfunction.

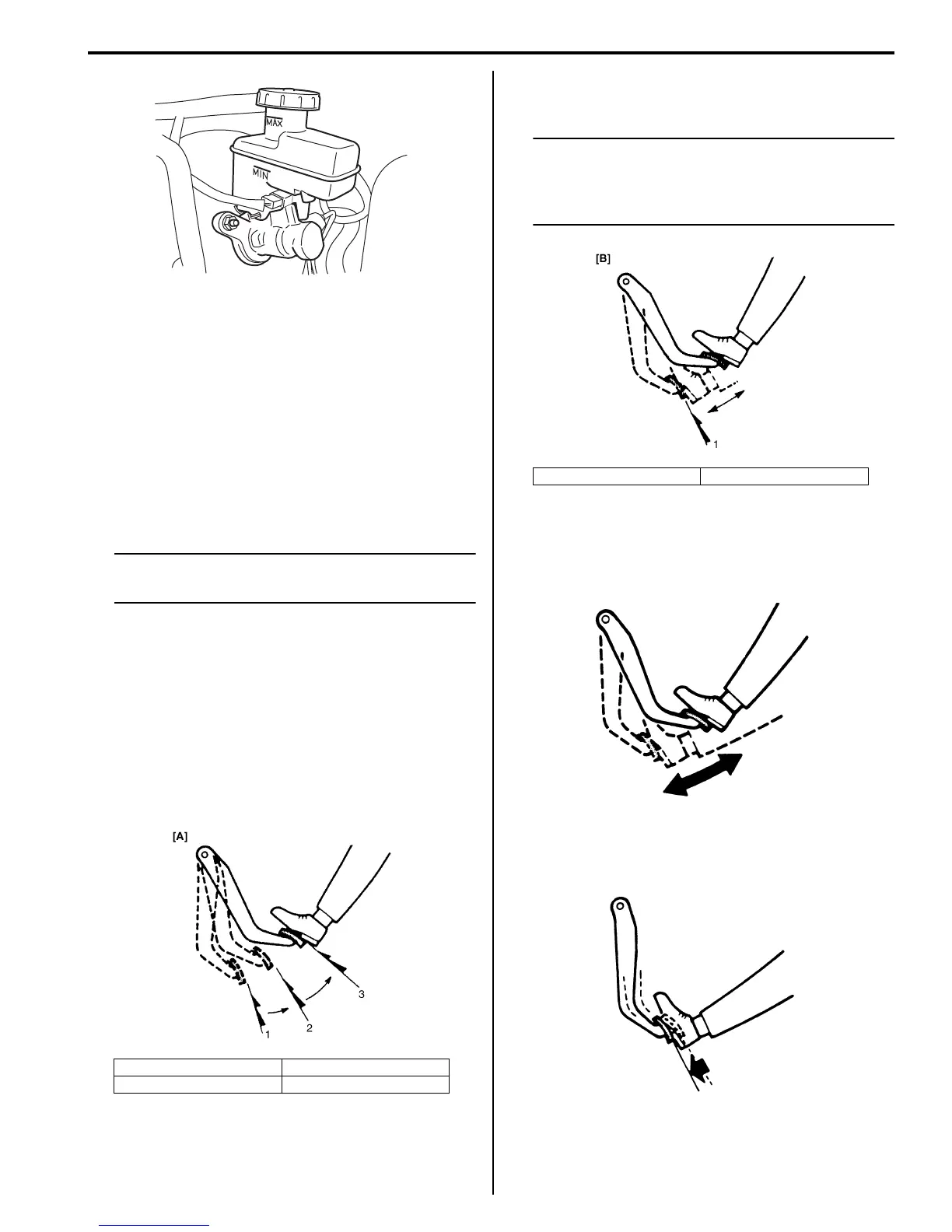

[A]: Good 2. 2nd

1. 1st 3. 3rd

I5JB0A410005-01

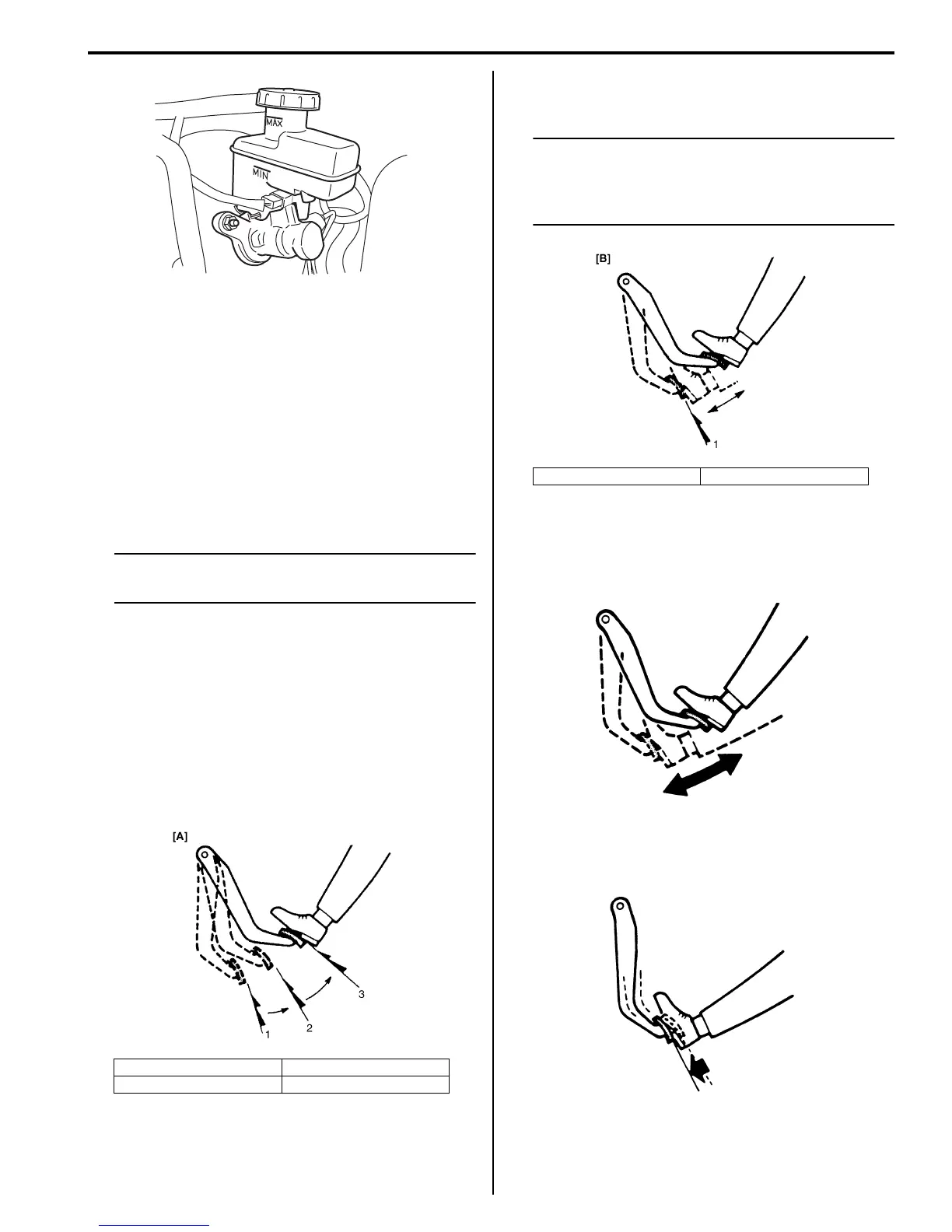

I5JB0A410008-01

[B]: No Good 1. 1st, 2nd, 3rd

I5JB0A410009-01

IYSQ01410018-01

IYSQ01410019-01

Loading...

Loading...