1D-32 Engine Mechanical:

b) Install the 2nd ring (3) and 1st ring (4) to piston.

NOTE

1st ring (4) and 2nd ring (3) differ in shape.

NOTE

Face the stamped mark “C” upward when

assembling.

2) Position the gaps of the three rings and side rails as

shown. Before inserting piston into the cylinder,

check that the gaps are so located.

3) Install the piston and piston pin. Refer to “Engine Top

Side Assembly (Page 1D-13)”.

Piston and Piston Ring Inspection

B827H11406032

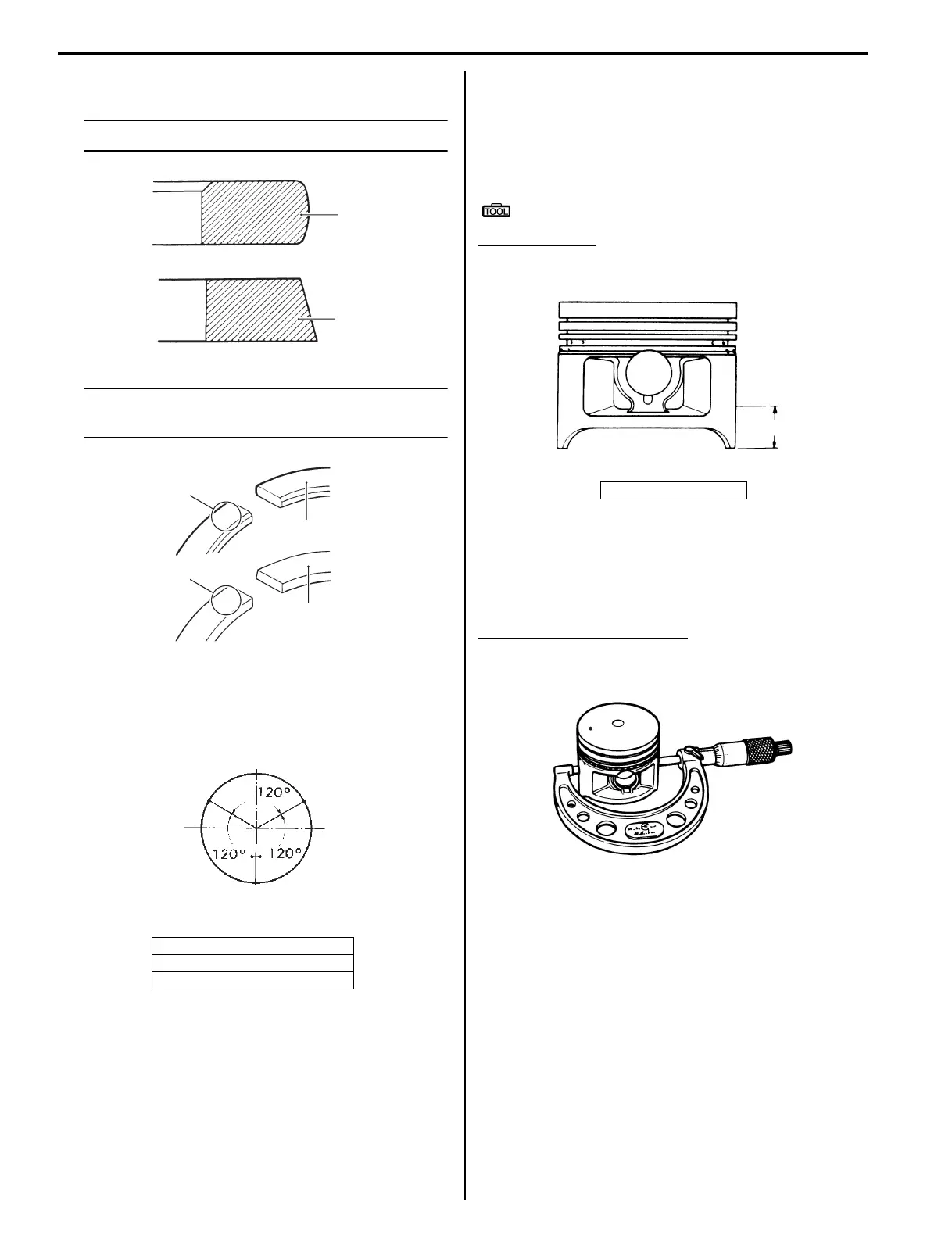

Piston Diameter

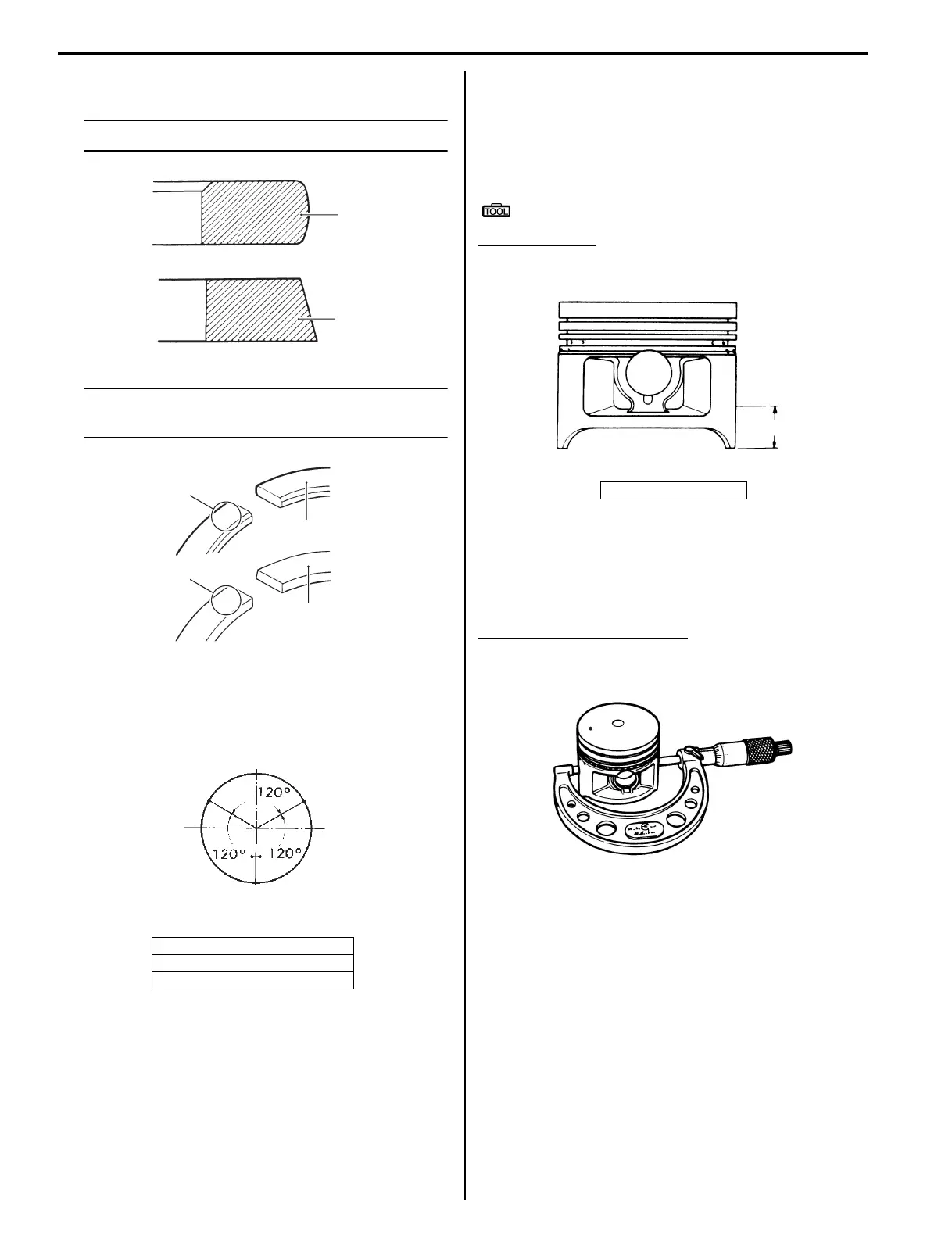

Using the micrometer, measure the piston outside

diameter at the place shown in figure. If the

measurement is less than the limit, replace the piston.

Special tool

: 09900–20210 (Micrometer (100 – 125 mm))

Piston diameter

Service limit: 81.880 mm (3.2236 in)

Piston-to-cylinder Clearance

Subtract the piston diameter from the cylinder bore

diameter. If the piston-to-cylinder clearance exceeds the

following limit, overhaul the cylinder and use an oversize

piston, or replace both cylinder and the piston.

Piston-to-cylinder clearance

Service limit: 0.120 mm (0.0047 in)

Piston oversize: 0.5

“D”: 2nd ring and lower side rail

“E”: Upper side rail

“F”: 1st ring and spacer

3

4

I827H1140086-02

R

R

3

4

“C”

“C”

I827H1140087-02

EX

IN

“D”

“E”

“F”

I831G1140181-03

“a”: 15 mm (0.6 in)

“a”

I827H1140088-01

I827H1140089-01

Loading...

Loading...