3D-10 Propeller Shafts:

• After reassembling the universal joint, check the joint

movement smoothly. If a large resistance is felt to

movement, tap the bearing with a plastic mallet lightly.

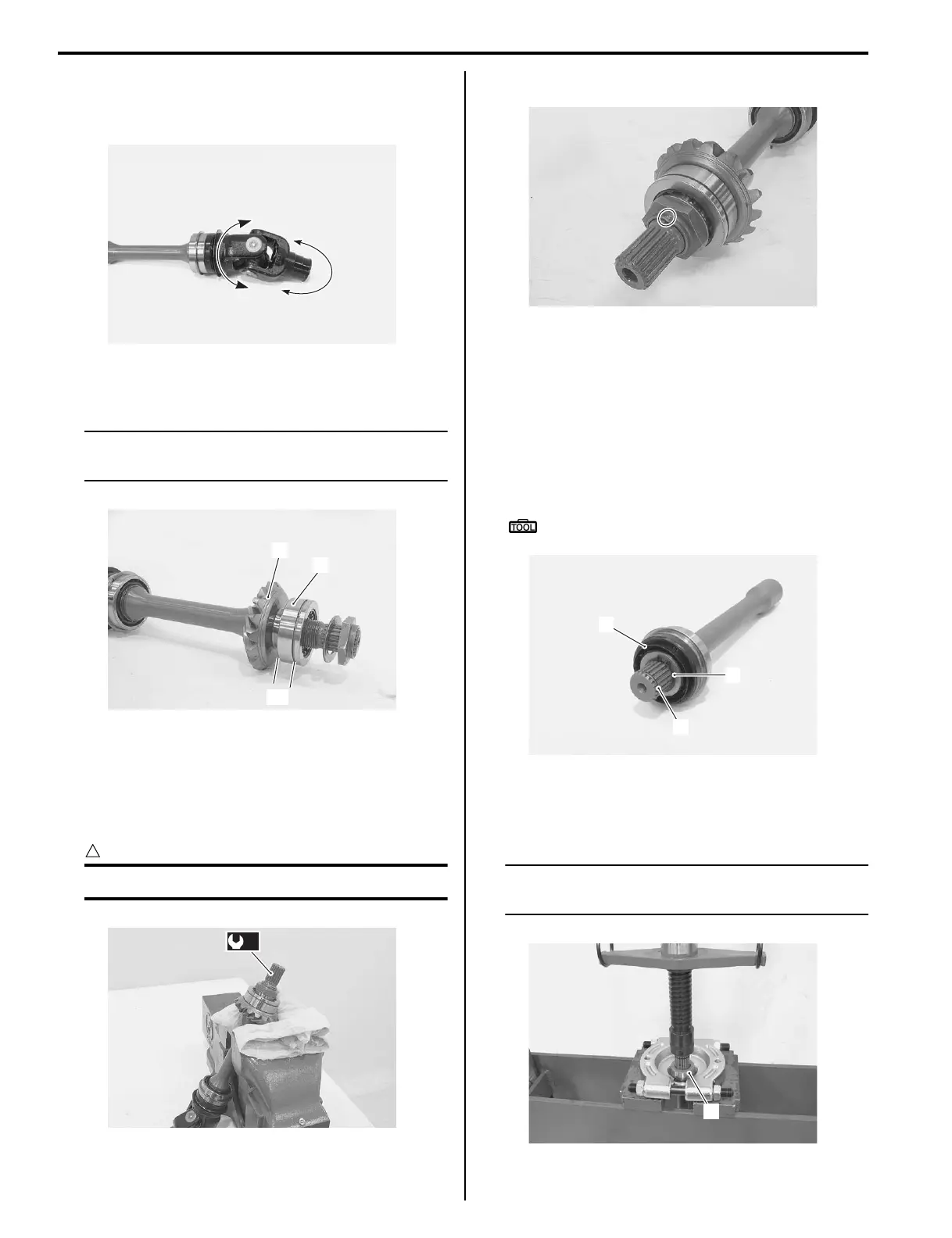

• Install the driven bevel gear (4), bearing (5), washer

and nut.

NOTE

The wider side “C” of the bearing should be

positioned driven bevel gear side.

• With the rear output shaft held immovable with a vise,

tighten new nut to the specified torque.

Tightening torque

Driven bevel gear nut (a): 100 N·m (10.0 kgf-m,

72.5 lb-ft)

CAUTION

!

Replace the removed nut with a new one.

• Stake the nut with a center punch.

Front Output Shaft Disassembly and Assembly

(LT-A400F, LT-F400F)

B827H13406018

Refer to “Output Shaft Removal and Installation

(Page 3D-3)”.

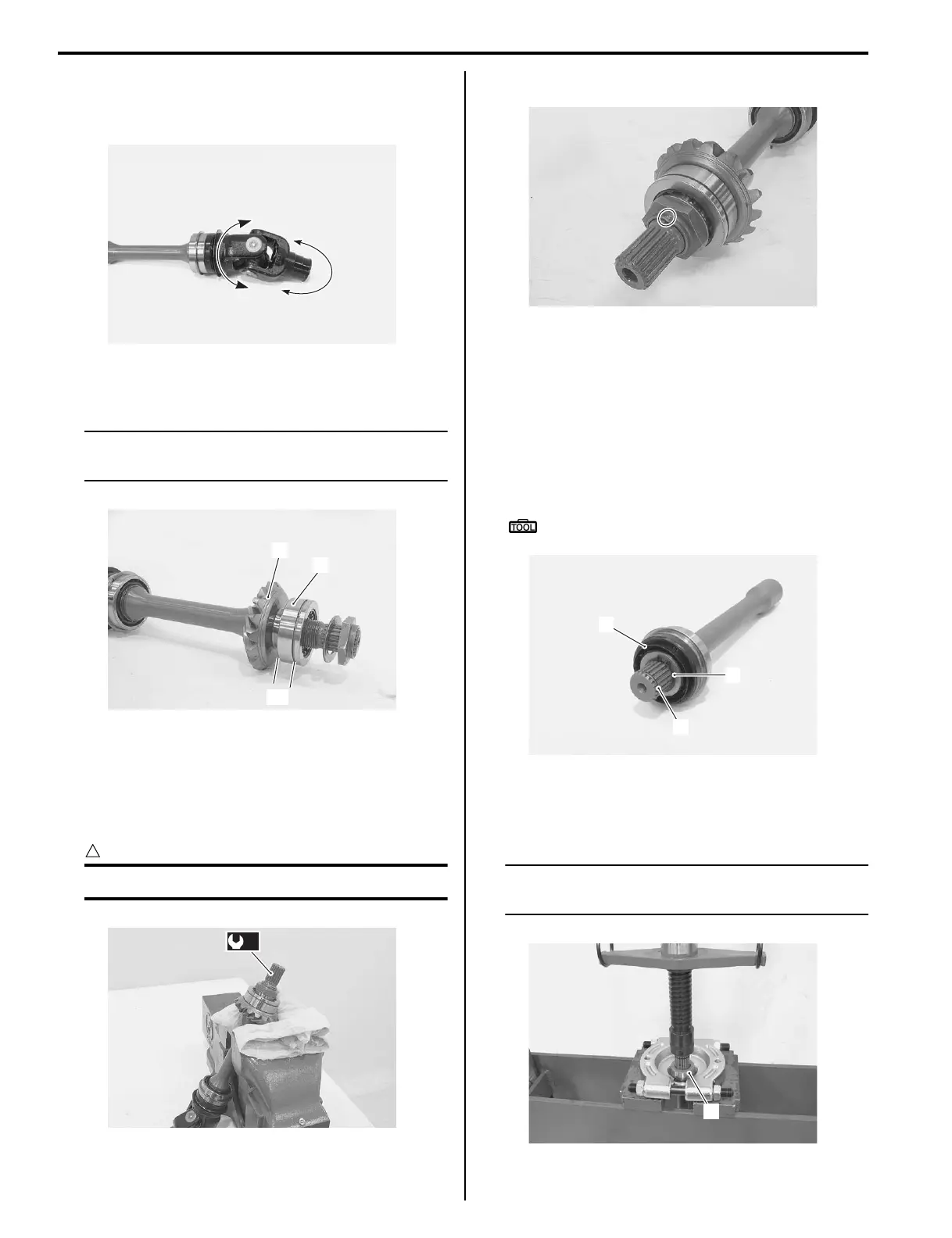

Disassembly

1) Remove the oil seal (1), circlip (2) and snap ring (3).

Special tool

: 09900–06107 (Snap ring pliers)

2) Remove the spacer (4) using a commercially

available bearing puller and hydraulic press.

3) Remove the bearing.

NOTE

If there is no abnormal noise, the spacer and

bearing removal is not necessary.

I827H1340050-02

“C”

5

4

I827H1340051-03

(a)

I827H1340052-01

I827H1340053-01

1

3

2

I827H1340054-02

4

I827H1340087-01

Loading...

Loading...