E - Checking installation position of sender wheel on crankshaft

⇒ Page 176.

F - Re-pressing sender wheel ⇒ Page 177.

2.5.1 Pressing out sealing flange with sender

wheel

Note

For the sake of clarity, the work is performed with the engine re-

moved.

– Remove flywheel ⇒ Page 167, Assembly overview - sealing

flanges and flywheel.

– Remove intermediate plate.

– Set engine to TDC for no. 1 cylinder ⇒ Page 210, Removing

and installing toothed belt.

– Drain engine oil ⇒ Page 245.

Note

Observe environmental regulations for disposal.

– Remove sump ⇒ Page 244.

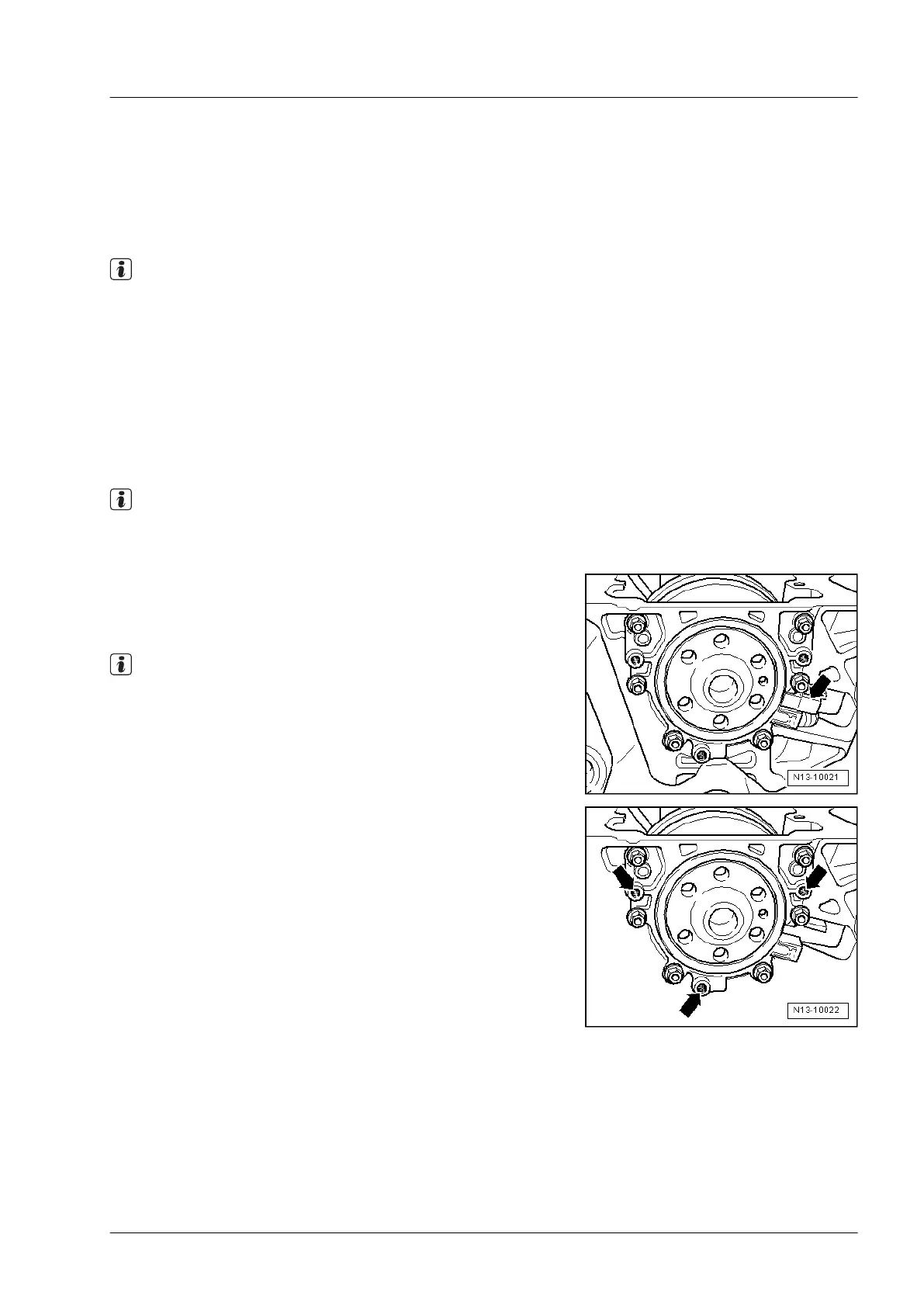

– Remove engine speed sender -G28- -arrow- using a com-

mercially available ball-ended hex key socket.

– Unscrew sealing flange securing bolts.

Note

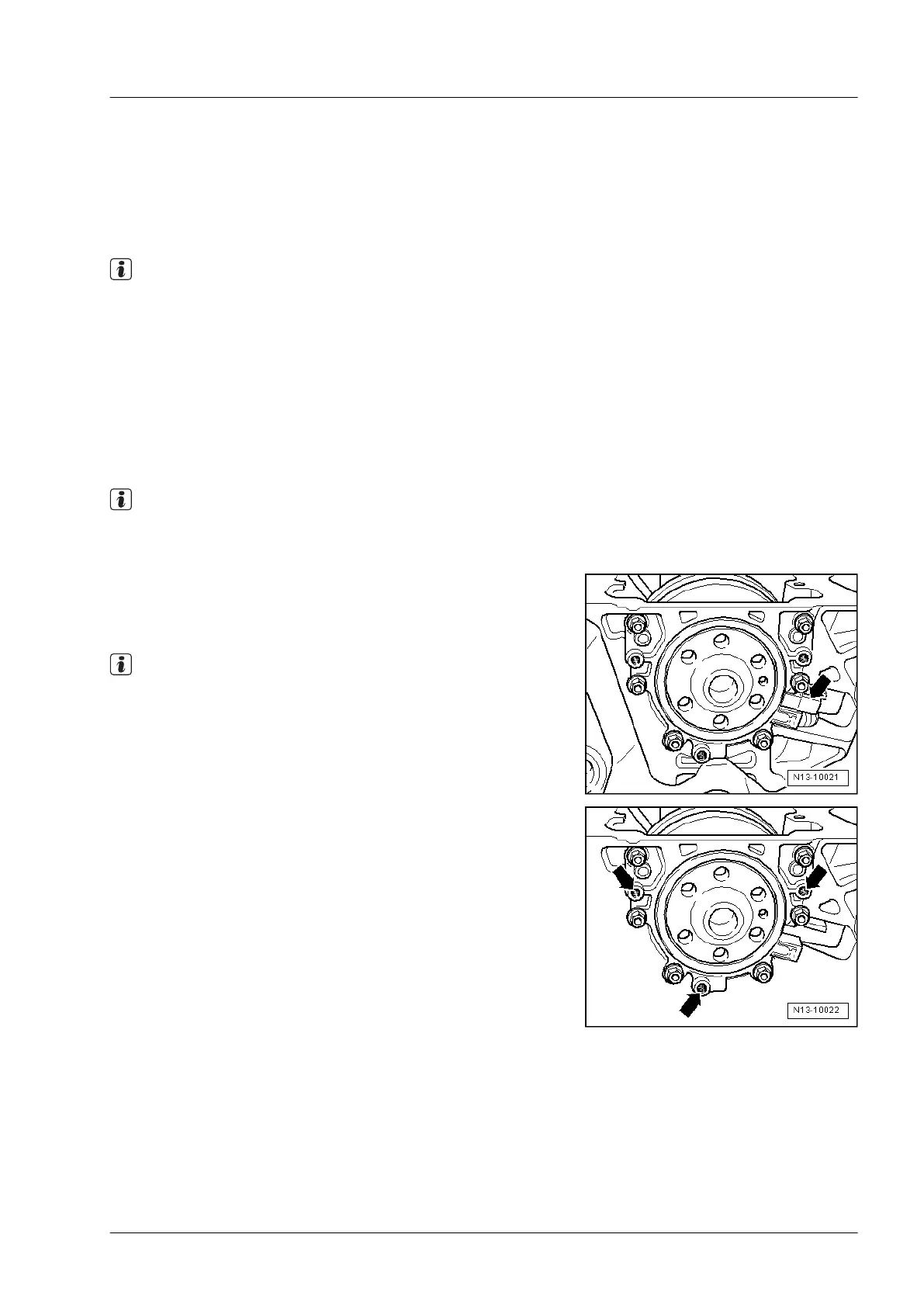

Sealing flange and sender wheel are pressed off the crankshaft

together using three M6 x 35 mm bolts.

– Screw three M6 x 35 mm bolts into threaded holes -arrows-

of sealing flange.

– Screw bolts alternately (max.

1

/

2

turn (180 °) for each bolt)

into sealing flange and press sealing flange together with

sender wheel off crankshaft.

Industriemotoren - Industrial Engines 2009 ▶

Workshop Manual for Diesel Engine (2.0 l/36-75 kW_EA 189) 05.2015

3

2 Removing and installing sealing flange and flywheel

171

Loading...

Loading...