2.5.2 Pressing in sealing flange with sender

wheel

Note

◆ The sealing flange with a PTFE seal is equipped with a seal-

ing lip support ring. This support ring serves as a fitting

sleeve and must not be removed prior to installation.

◆ Sealing flange and sender wheel must not be separated or

turned after removal from packaging.

◆ The sender wheel is held in its installation position on the as-

sembly device -T10134- by a locating pin.

◆ Sealing flange and oil seal form one unit and must only be

renewed together with the sender wheel.

◆ The assembly device -T10134- is held in its position relative

to the crankshaft by a guide pin inserted into a hole in the

crankshaft.

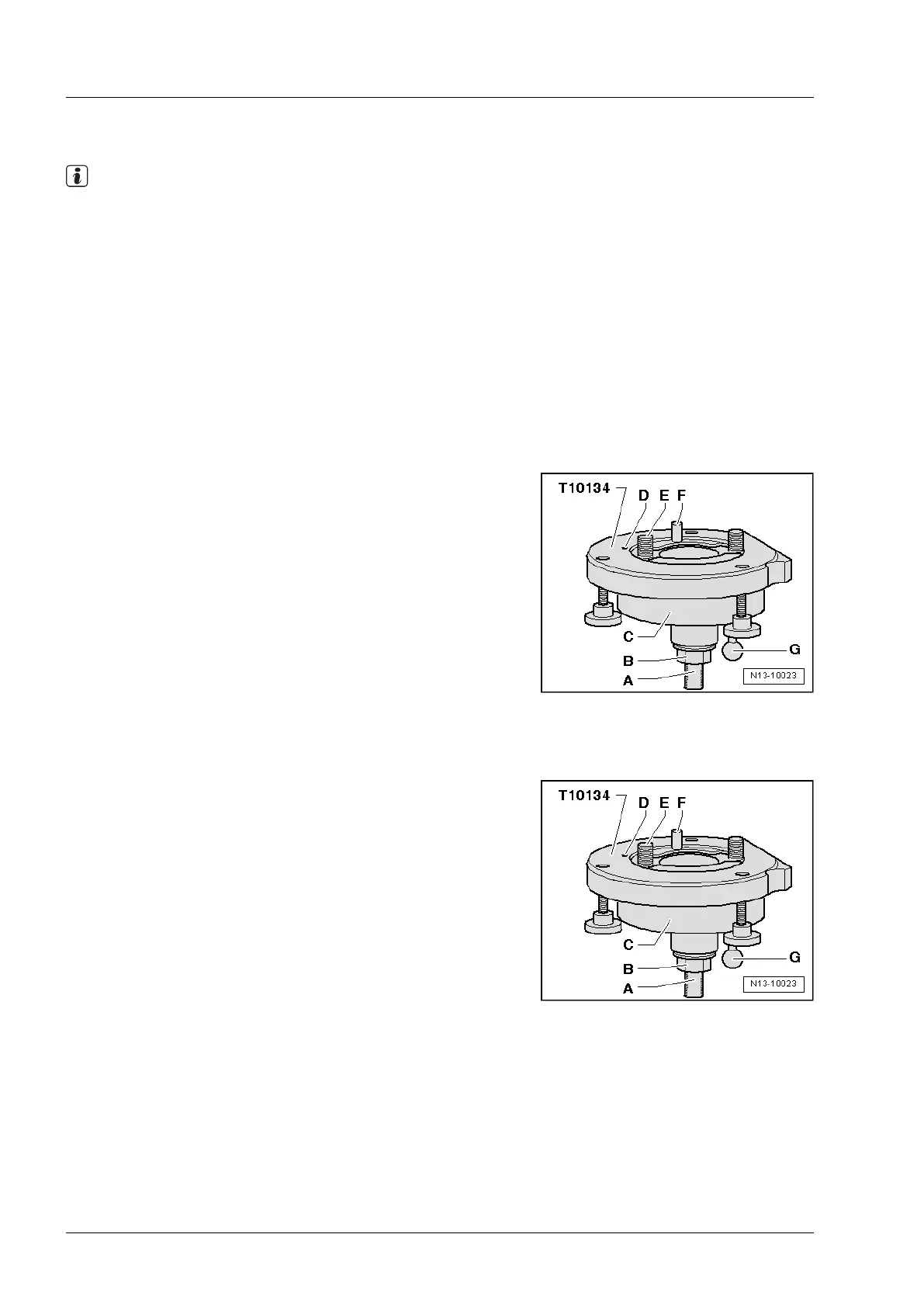

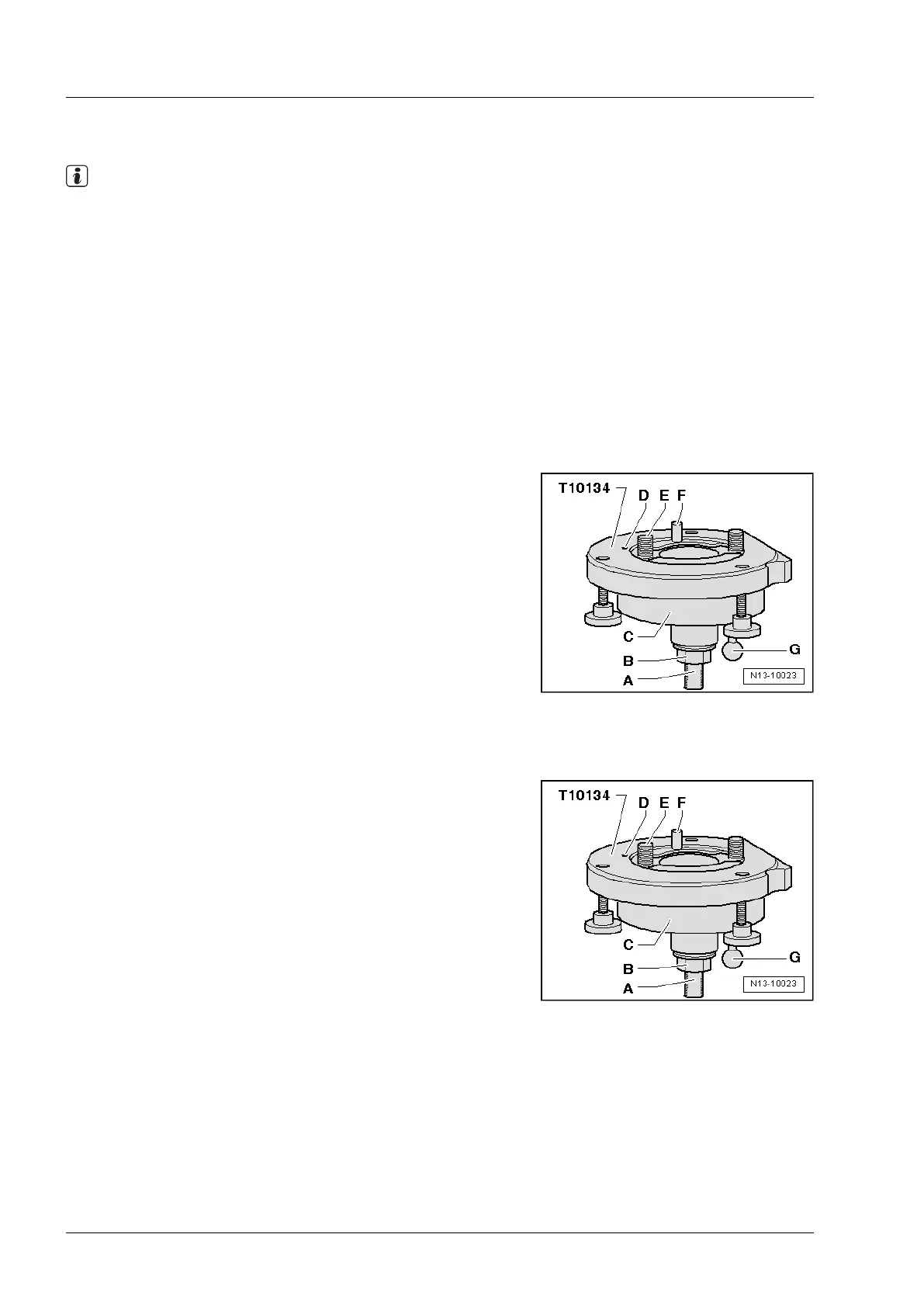

Assembly tool -T10134-

A - Clamping surface

B - Hexagon nut

C - Assembly housing

D - Locating pin

E - Hexagon socket head bolt

F - Guide pin for diesel engines (black knob)

G - Guide pin for petrol engines (red knob)

2.5.3 A - Assembling seal with sender wheel on

assembly tool -T10134-

– Screw in hexagon nut -B- to just before clamping surface -A-

of threaded spindle.

3

Industriemotoren - Industrial Engines 2009 ▶

Workshop Manual for Diesel Engine (2.0 l/36-75 kW_EA 189) 05.2015

172

Repair Group 13 - Crankshaft group

Loading...

Loading...