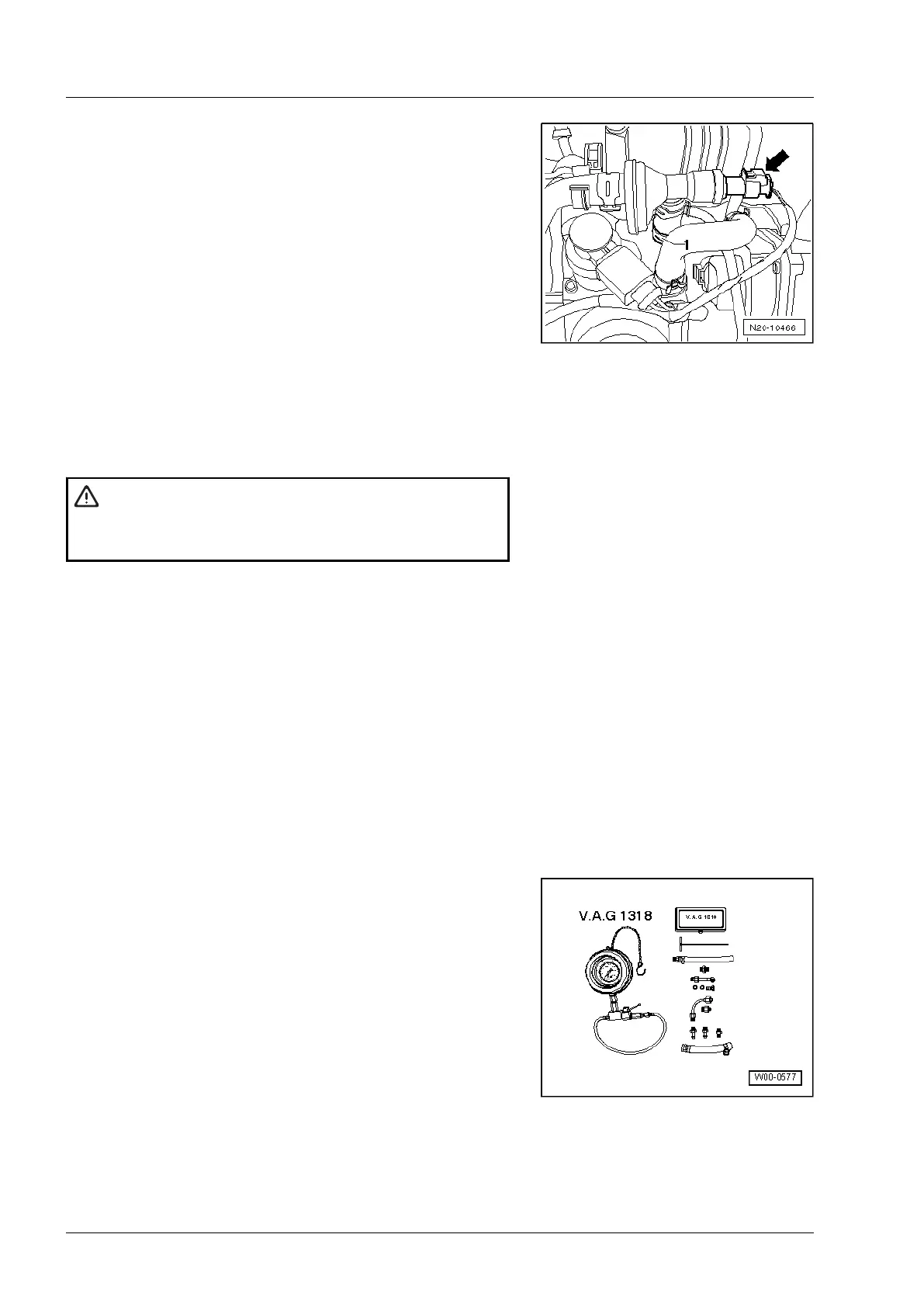

– Disconnect connector from fuel temperature sender -G81-

-arrow-, loosen clamp -1-, and pull fuel supply line off high-

pressure pump.

– Unscrew securing bolts of supplementary fuel pump -V393-.

Installing

Install in reverse order. In the process, note the following:

◆ Route fuel hoses without kinking.

◆ Ensure that fuel hose connections are tight.

◆ Do not interchange supply and return lines.

◆ Clip fuel and coolant hoses into retainers again.

2 Checking components and func-

tions

WARNING

Adhere to the general safety regulations and the notes on

repair work on the engine! ⇒ Page 1

The described component checks and functional checks are ap-

plicable for the series components and the current flow dia-

grams as of page ⇒ Page 486, current flow diagrams.

If components and electric circuits differ, observe the notes of

the respective industrial engine customer.

Checking supplementary fuel pump -V393- (inline electronic

fuel pump) ⇒ Page 314.

Checking accelerator pedal position sender -G79-, if fitted

⇒ Page 316.

2.1 Checking supplementary fuel pump

-V393- (inline electronic fuel pump)

Special tools and workshop equipment required

◆ K-Jetronic pressure tester -V.A.G 1318-

3

Industriemotoren - Industrial Engines 2009 ▶

Workshop Manual for Diesel Engine (2.0 l/36-75 kW_EA 189) 05.2015

314

Repair Group 20 - Fuel supply system

Loading...

Loading...