Bearing shells - installation position ⇒ Page 186.

Checking piston projection at TDC ⇒ Page 187.

Piston and cylinder dimensions ⇒ Page 188

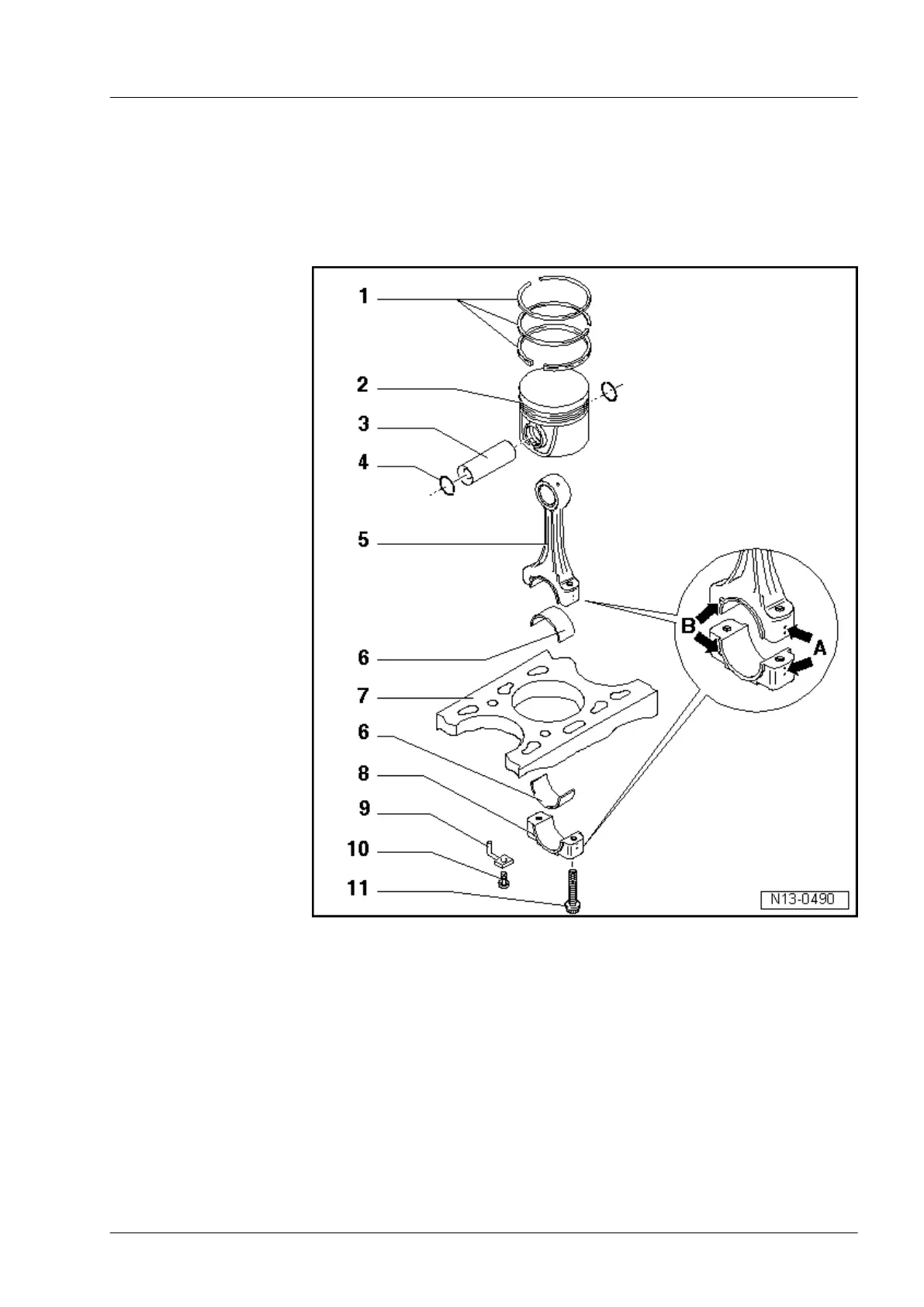

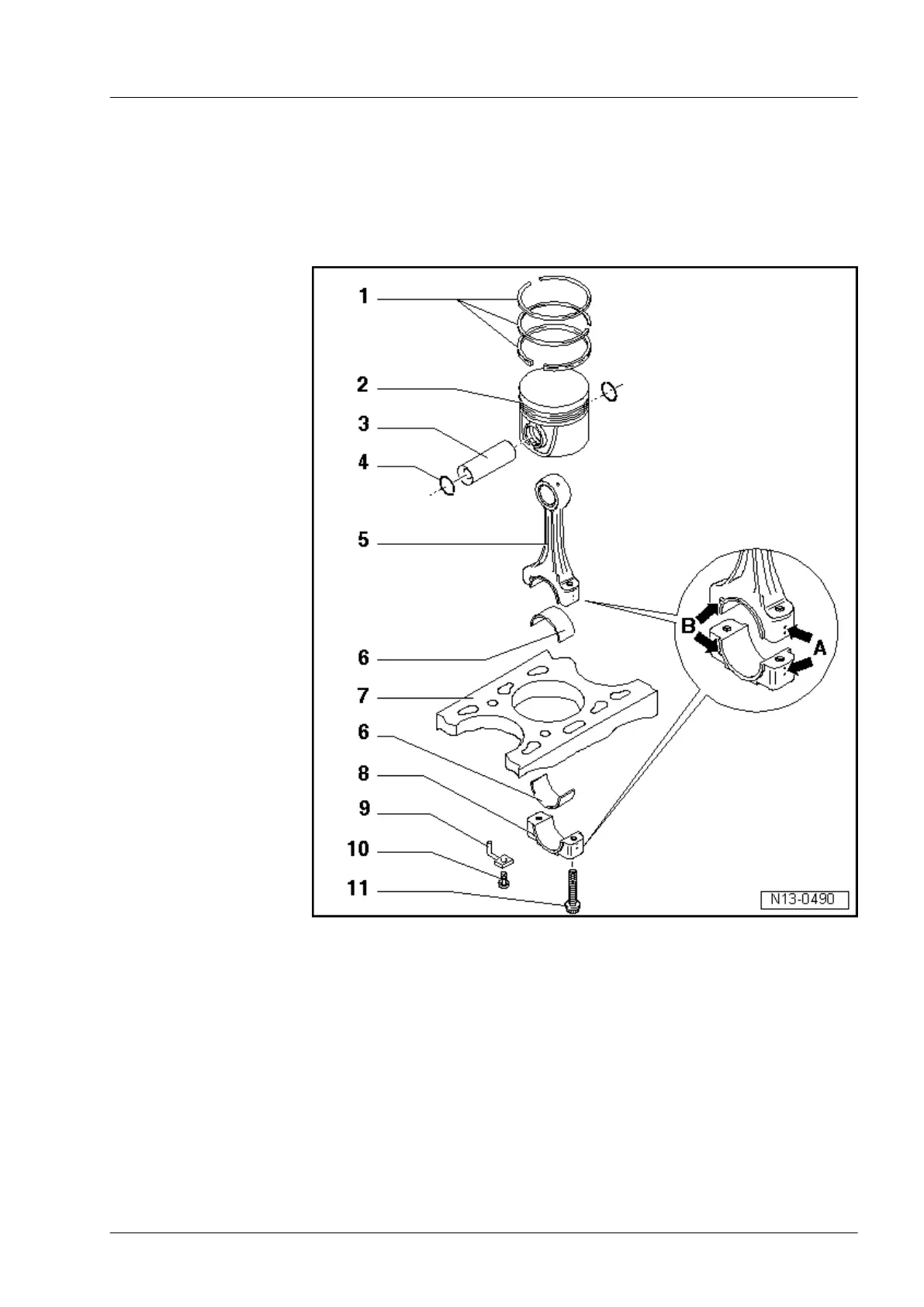

4.1 Assembly overview - pistons and conrods

1 - Piston rings

q Offset gaps by 120°.

q Use piston ring pli-

ers to remove and

install.

q “TOP” faces to-

wards piston crown.

q Checking ring gap

⇒ Fig. on page 184.

q

Checking ring-to-

groove clearance

⇒ Fig. on page 185.

2 - Piston

q

Mark installation po-

sition and cylinder

number.

q

Installation position

and allocation of

piston to cylinder

⇒ Fig. on page 185.

q Arrow on piston

crown points to belt

pulley end.

q Install using piston

ring clamp.

q If piston skirt is

cracked, renew pis-

ton.

q Checking piston

projection at TDC

⇒ Page 187.

3 - Piston pin

q If difficult to remove,

heat piston to 60°C

q Remove and install using drift -VW 222 a-.

4 - Retaining ring

5 - Conrod

q Mark with cylinder number -A-.

q Installation position: Marking -B- faces towards pulley end.

q With industrially cracked conrod cap.

q Separate new conrod ⇒ Page 185

6 - Bearing shell

q Note installation position ⇒ Page 186

q Do not interchange used bearing shells.

Industriemotoren - Industrial Engines 2009

▶

Workshop Manual for Diesel Engine (2.0 l/36-75 kW_EA 189) 05.2015

3

4 Dismantling and assembling pistons and conrods

183

Loading...

Loading...