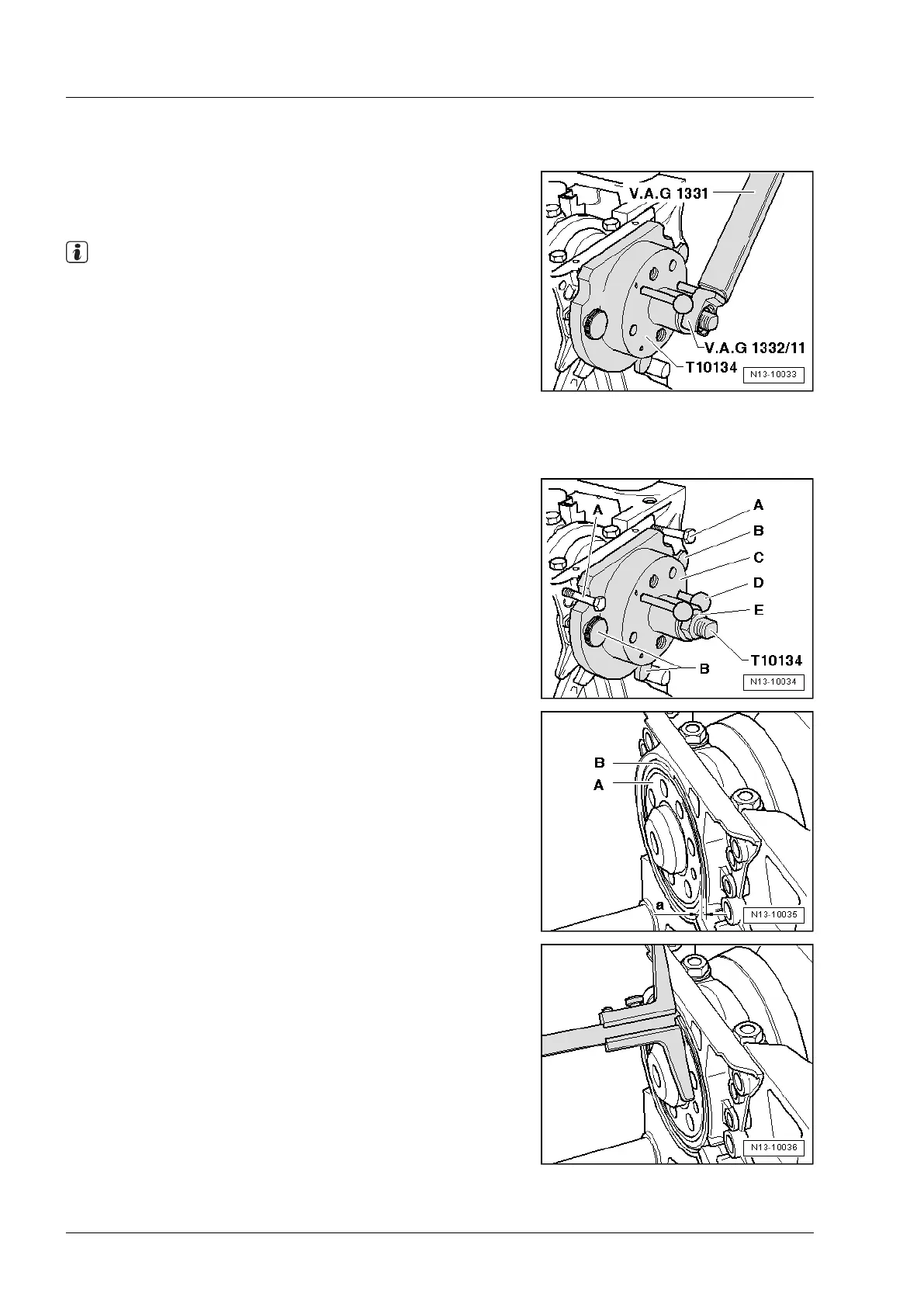

2.5.6 D - Pressing sender wheel onto crankshaft

flange using assembly tool -T10134-

– Tighten hexagon nut of assembly tool -T10134- to 35 Nm us-

ing torque wrench -V.A.G 1331- and tool insert, 24 mm

-V.A.G 1332/11-.

Note

After the hexagon nut is tightened to 35 Nm, there must still be

a small air gap between cylinder block and sealing flange.

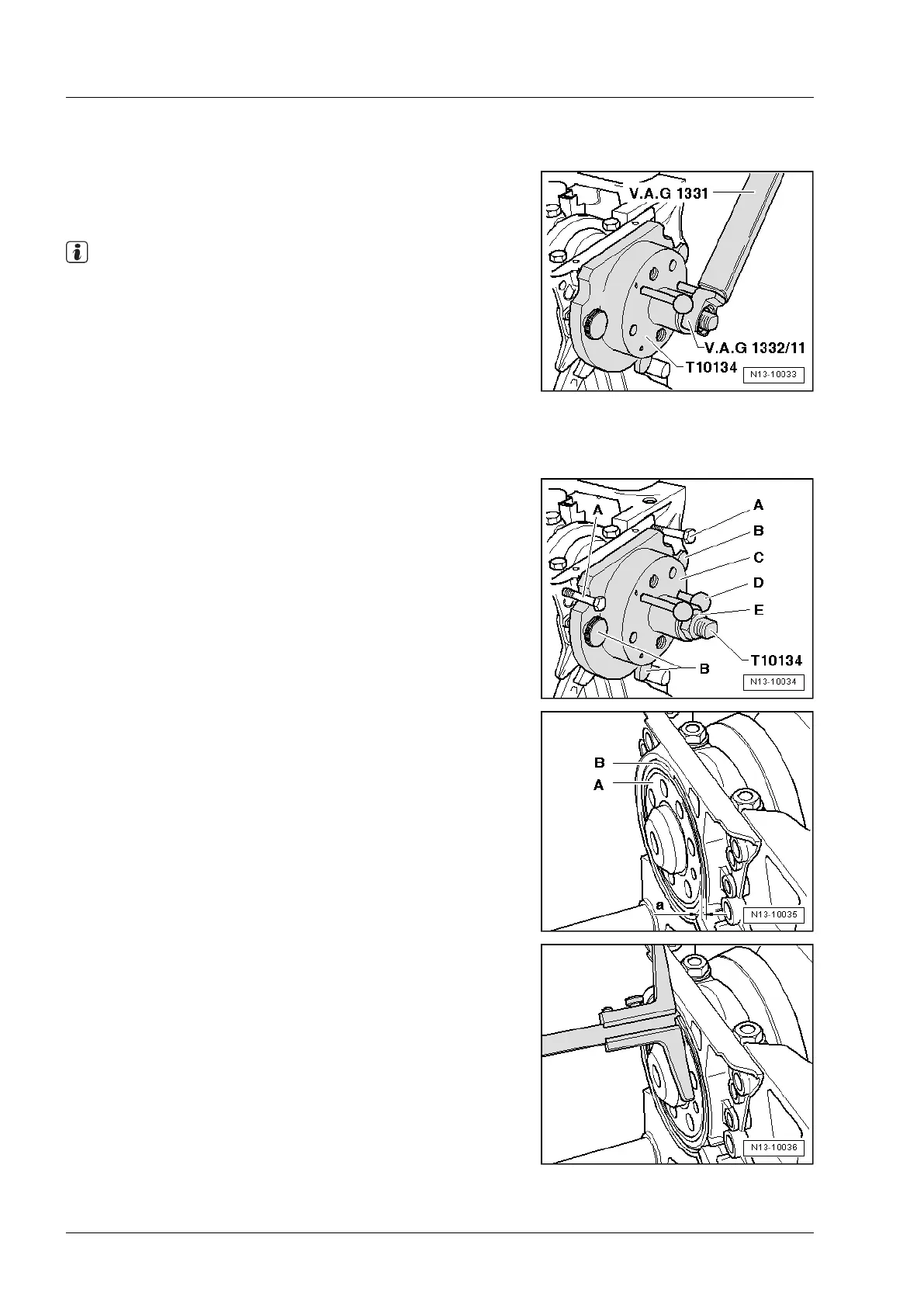

2.5.7 E - Checking installation position of sender

wheel on crankshaft

– Screw hexagon nut -E- to end of threaded spindle.

– Remove the two bolts -A- from cylinder block.

– Loosen the two hexagon socket head bolts.

– Screw the three knurled screws -B- out of sealing flange.

– Remove assembly tool -T10134-.

– Remove sealing lip support ring.

– The sender wheel is in the correct installation position on the

crankshaft if a gap -a- = 0.5 mm exists between crankshaft

flange -A- and sender wheel -B-.

– Set vernier gauge on crankshaft flange.

– Measure distance -a- between crankshaft flange and sender

wheel.

If measurement -a- is too small:

– Re-press sender wheel ⇒ Page 177.

If dimension -a- is attained:

– Tighten new securing bolts for sealing flange to 15 Nm using

alternate and diagonal sequence.

3

Industriemotoren - Industrial Engines 2009 ▶

Workshop Manual for Diesel Engine (2.0 l/36-75 kW_EA 189) 05.2015

176

Repair Group 13 - Crankshaft group

Loading...

Loading...