11 - Gasket

q Renew

12 - 25 Nm

13 - Lifting eye

14 - Cylinder head gasket

q Renew

q Note marking ⇒ Fig. on page 191.

q After renewing, renew entire coolant.

15 - Hall sender -G40-

q For camshaft position.

q Check ⇒ Page 403

q Removing and installing ⇒ Page 191

16 - 10 Nm

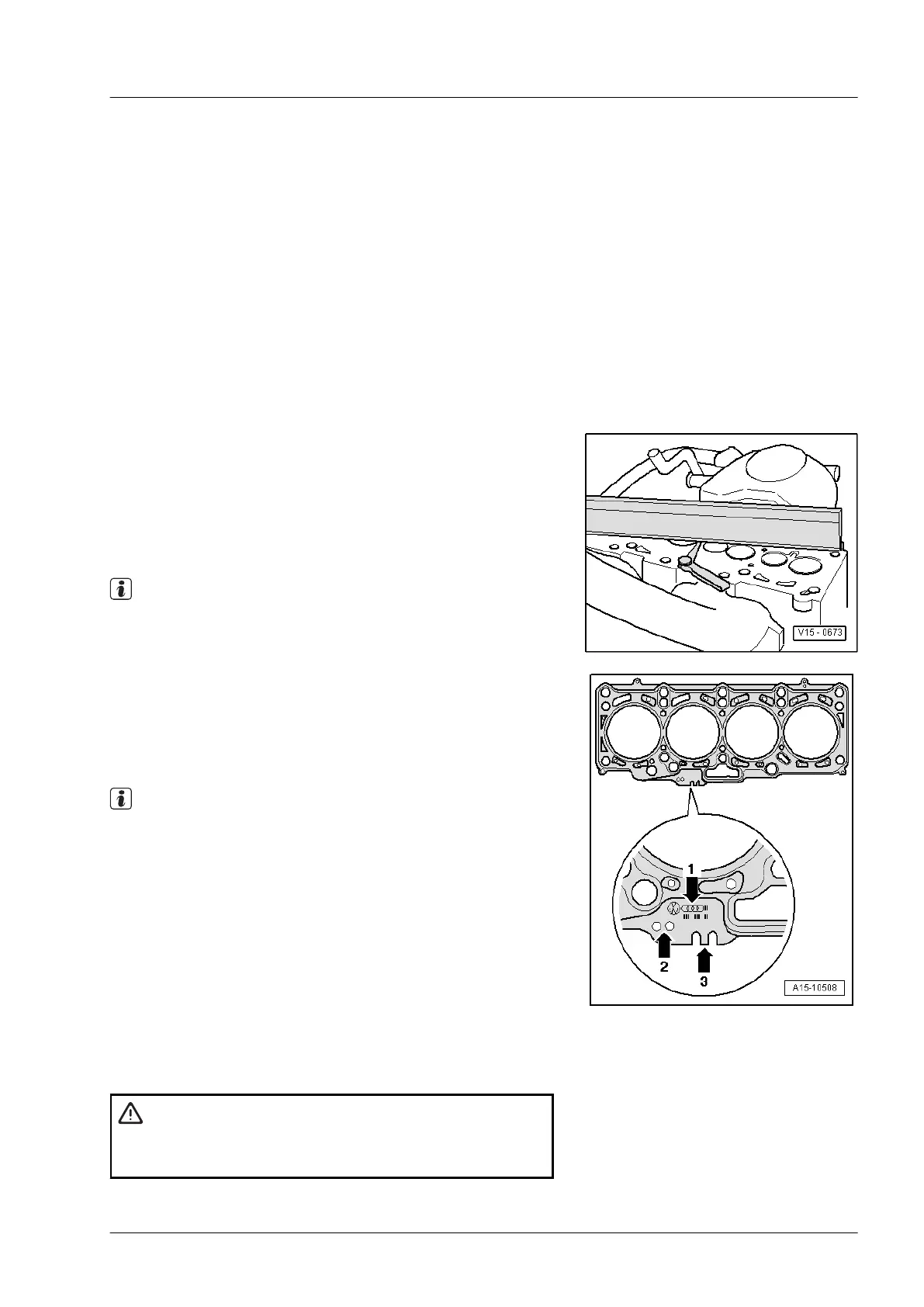

Checking cylinder head for distortion

Special tools and workshop equipment required

◆ Straightedge 500 mm -VAS 6075-

◆ Feeler gauges

Max. permissible distortion: 0.1 mm.

Note

Reworking diesel cylinder heads is not permissible.

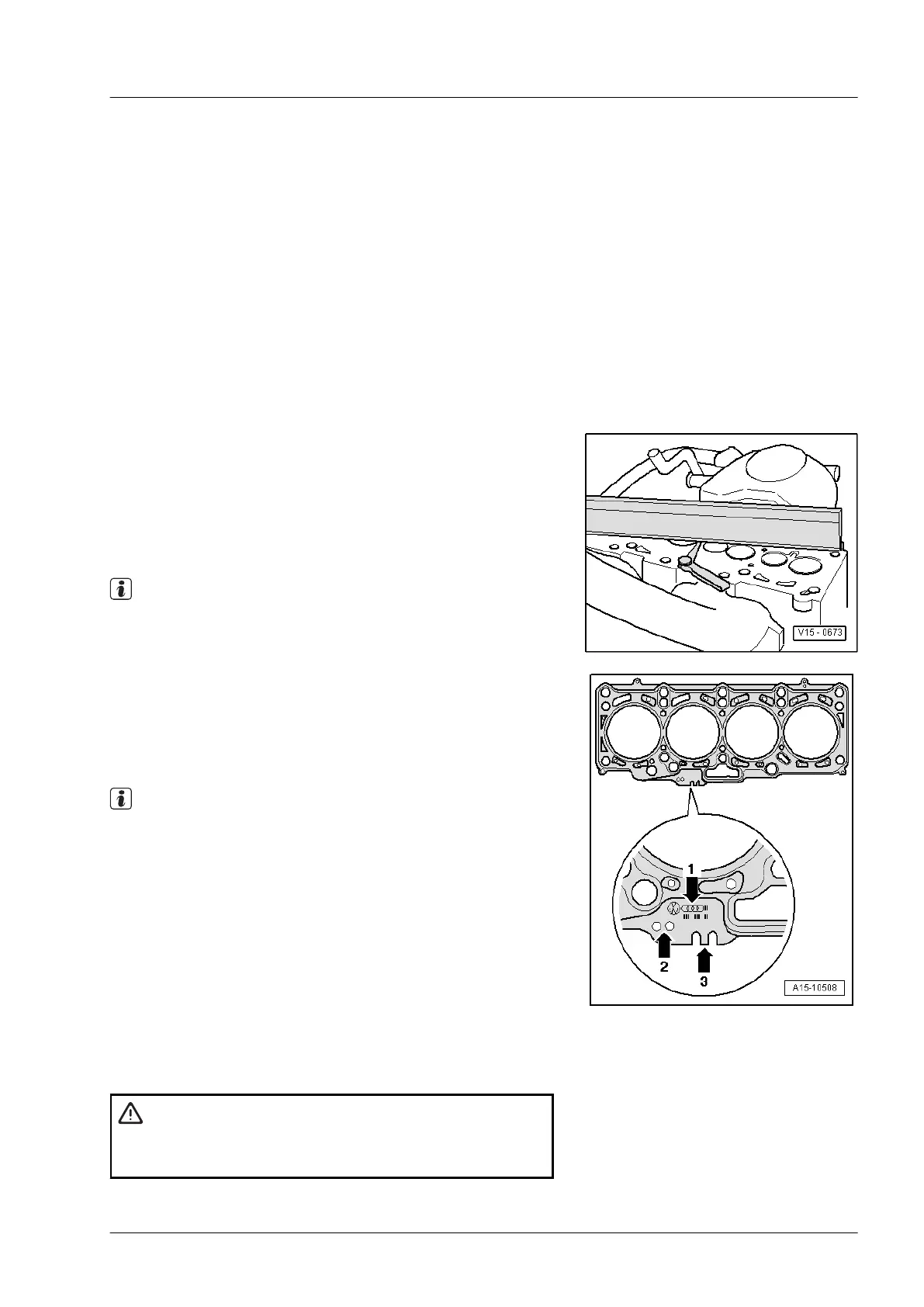

Cylinder head gasket identification

◆ Part number = arrow 1

◆ Holes = arrow 2

◆ Production control code = arrow 3 (can be disregarded)

Note

◆ Different thicknesses of cylinder head gasket are fitted de-

pending on the piston projection. When the seal is renewed,

ensure that the designation matches.

◆ Piston projection at TDC must be determined when installing

new pistons or a short engine. ⇒ Page 213.

1.2 Removing and installing Hall sender

-G40-

WARNING

Adhere to the general safety regulations and the notes on

repair work on the engine! ⇒ Page 1

Industriemotoren - Industrial Engines 2009 ▶

Workshop Manual for Diesel Engine (2.0 l/36-75 kW_EA 189) 05.2015

3

1 Cylinder head

191

Loading...

Loading...