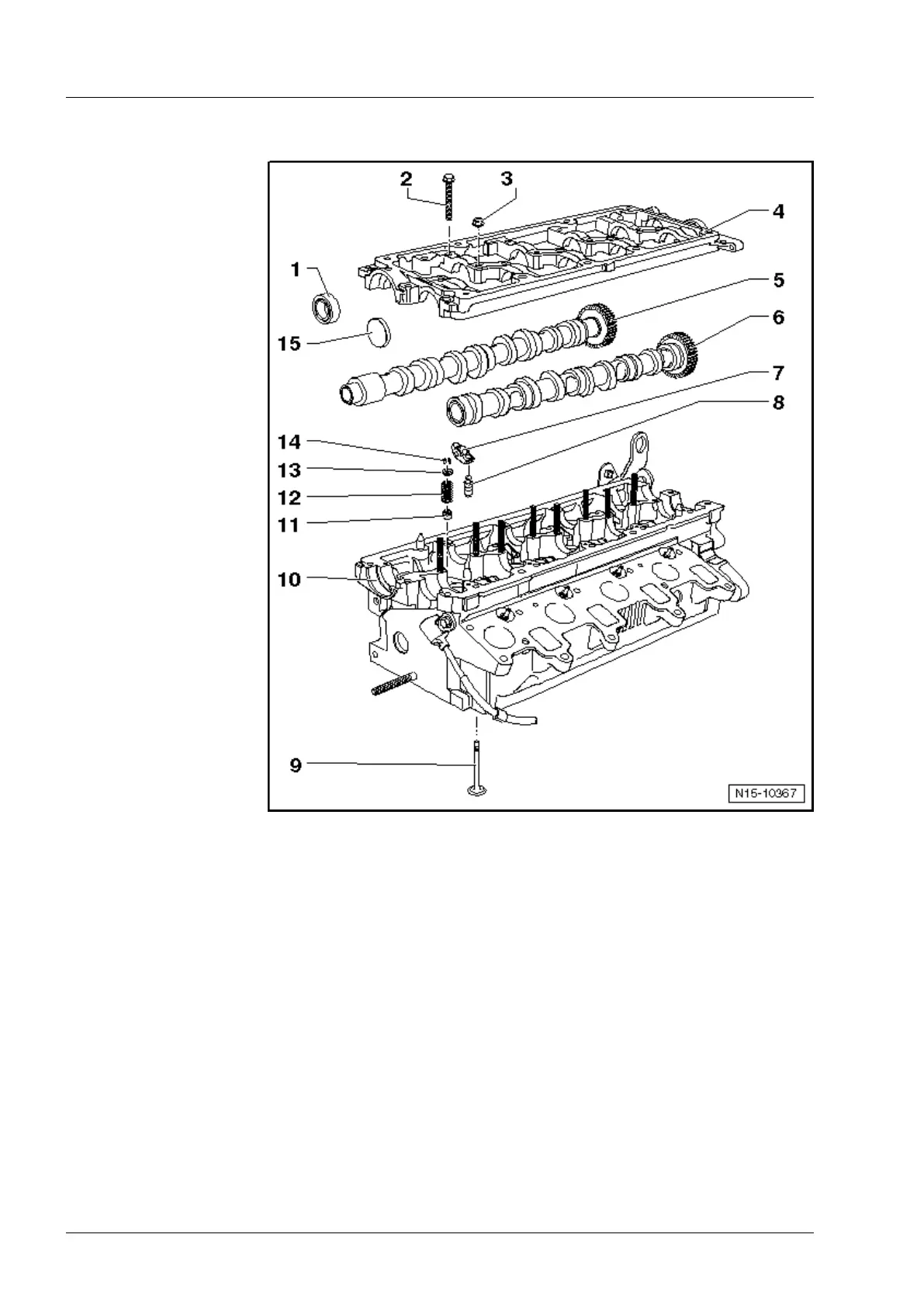

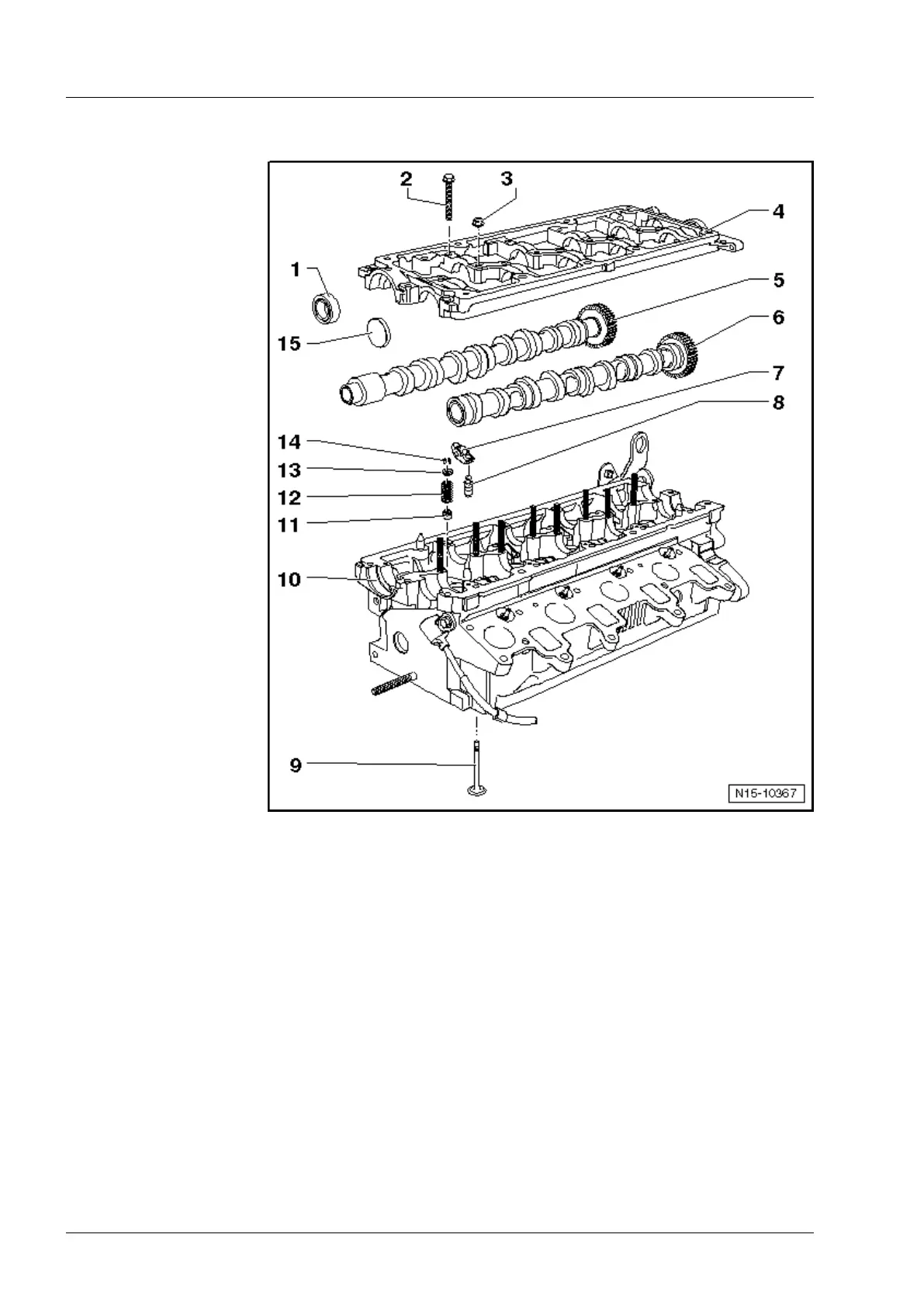

2.1 Assembly overview - valve gear

1 - Seal

q Do not additionally

oil or grease the oil

seal sealing lip.

q Before installing, re-

move residual oil

from camshaft jour-

nal using a clean

cloth.

q To install, mask off

groove on camshaft

taper (e.g. using

Sellotape)

q Removing and in-

stalling ⇒ Page 239

2 - 10 Nm

3 - 10 Nm

4 - Retaining frame

q

Observe sequence

when loosening and

tightening

⇒ Page 233.

q

Seal using silicone

adhesive sealant

D 176 501 A1.

5 -

Exhaust camshaft

6 -

Inlet camshaft

7 -

Roller rocker finger

q

Mark installation po-

sition.

q

Do not interchange.

q

Check roller bearing

for ease of movement.

q

Oil contact surface.

8 -

Hydraulic compensation element

q

Mark installation position.

q

Lubricate contact surfaces before installing.

9 -

Valve

q

Do not rework. Only lapping in is permitted.

q

Mark installation position for re-installation.

q

Valve dimensions ⇒ Page 229

q

Checking valve guides ⇒ Page 229.

10 -

Cylinder head

q

See note

q

Removing and installing.

11 -

Valve stem seal

12 -

Valve spring

3

Industriemotoren - Industrial Engines 2009 ▶

Workshop Manual for Diesel Engine (2.0 l/36-75 kW_EA 189) 05.2015

228

Repair Group 15 - Cylinder head, valve gear

Loading...

Loading...