208 Actual signals and parameters

Group 31: Automatic reset

This group defines conditions for automatic resets. An automatic reset occurs after a

particular fault is detected. The drive holds for a set delay time, then automatically

restarts. You can limit the number of resets in a specified time period, and you can set

up automatic resets for a variety of faults.

3023

WIRING FAULT

0, 1 1 1

Selects how the drive reacts when incorrect input power and motor cable connection

is detected (ie, the input power cable is connected to the motor connection of the

drive).

0 = DISABLE – No action.

1 = ENABLE – The drive trips on fault 0035 OUTP WIRING.

3027

OPTION COM LOSS

0, 1 1 1

Selects how the drive reacts when the MREL-01 output relay module is removed from

the drive, and parameters 1402 RELAY OUTPUT 2, 1403 RELAY OUTPUT 3 or 1410

RELAY OUTPUT 4 have non-zero values.

0 = DISABLE – Prevents the fault 1006 PAR EXT RO even when MREL-01 is

disconnected.

1 = ENABLE – MREL-01 is constantly monitored for disconnection. The drive trips on

fault 1006 PAR EXT RO if external relay outputs are configured for use.

Group 31: Automatic reset

Code Description Range Resolution Default S

3101

NUMBER OF

TRIALS

0…5 1 5

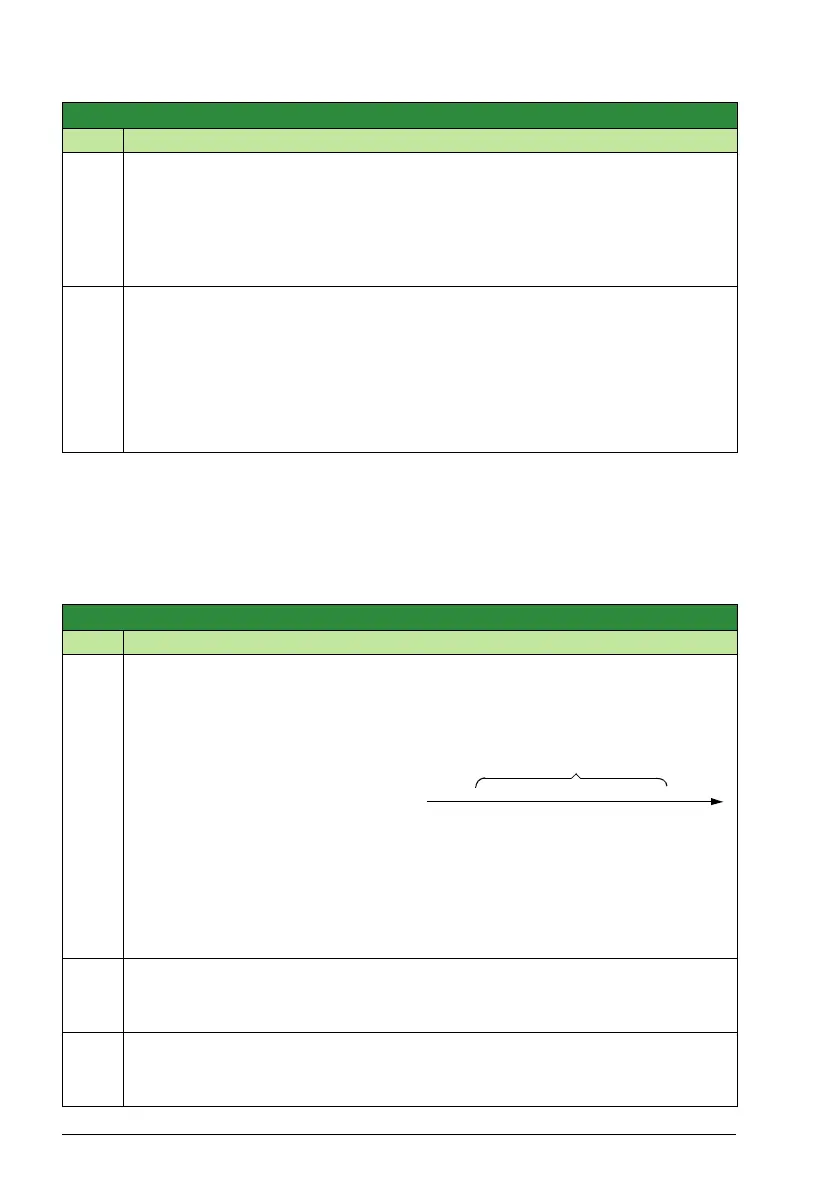

Sets the number of allowed automatic resets within a trial period defined by parameter

3102 TRIAL TIME.

• If the number of automatic resets

exceeds this limit (within the trial

time), the drive prevents additional

automatic resets and remains

stopped.

• Starting then requires a successful

reset performed from the control panel or from a source selected by parameter

1604 FAULT RESET SEL.

Example: Three faults have occurred in the trial time. The last is reset only if the value

for parameter 3101 NUMBER OF TRIALS is 3 or more.

3102

TRIAL TIME

1.0 … 600.0 s 0.1 s 30.0 s

Sets the time period used for counting and limiting the number of resets.

• See parameter 3101 NUMBER OF TRIALS.

3103

DELAY TIME

0.0 … 120.0 s 0.1 s 0.0 s

Sets the delay time between a fault detection and attempted drive restart.

• If DELAY TIME = zero, the drive resets immediately.

Group 30: Fault functions

Code Description Range Resolution Default S

XXX

Time

Trial time

x = Automatic reset

Loading...

Loading...