246 Actual signals and parameters

Group 44: Pump protection

This group defines the parameters used for the set-up of pump protection.

Group 44: Pump protection

Code Description Range Resolution Default S

4401

INLET PROT CTRL

NOT SEL

Enables, and selects the mode of, the primary supervision of pump/fan inlet pressure.

Note: Inlet protection is active only when the active reference is PID.

0 = NOT SEL – Primary inlet pressure supervision not used.

1 = ALARM – Detection of low inlet pressure generates an alarm on the control panel

display.

2 = PROTECT – Detection

of low inlet pressure

generates an alarm on

the control panel

display. The output of

the PI controller is

ramped down

(according to

parameter 4417 PID

OUT DEC TIME) to the

forced reference (set

by parameter 4008

INLET FORCED REF).

The drive will revert to

the original reference if

the pressure

subsequently exceeds

the supervision level.

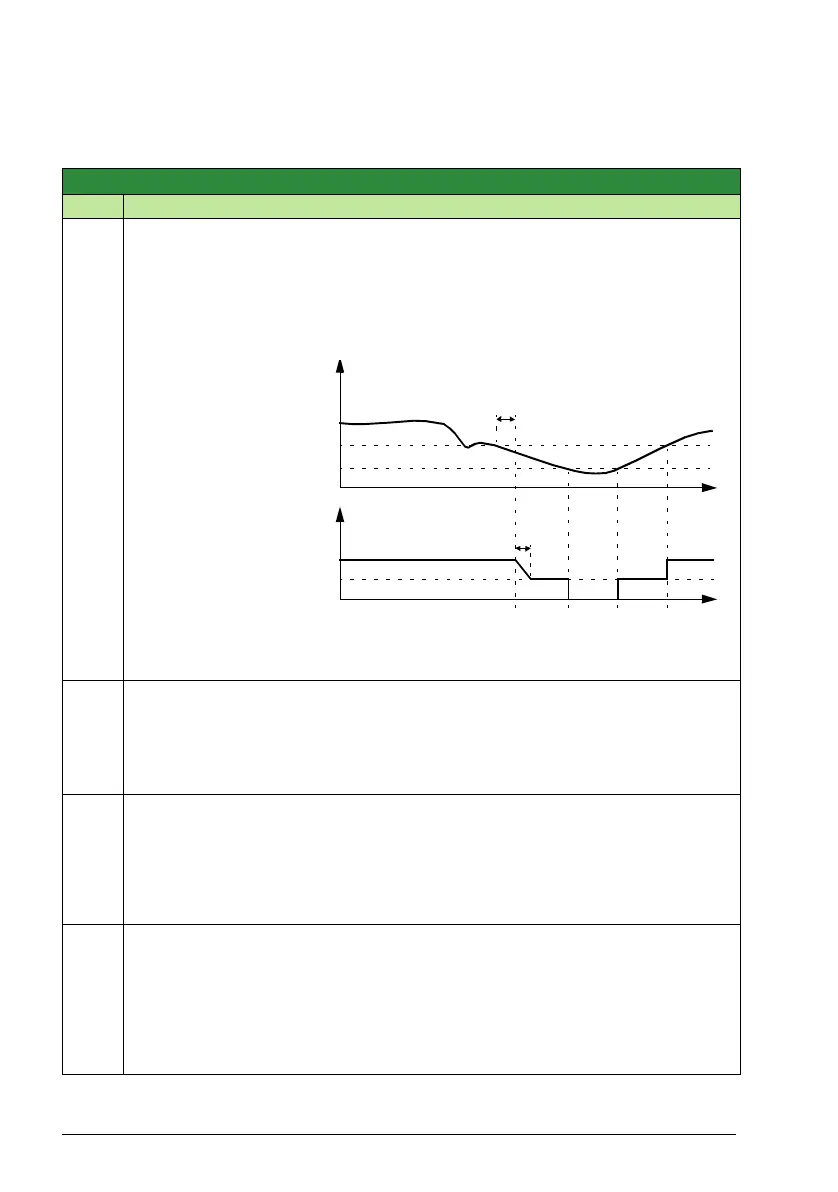

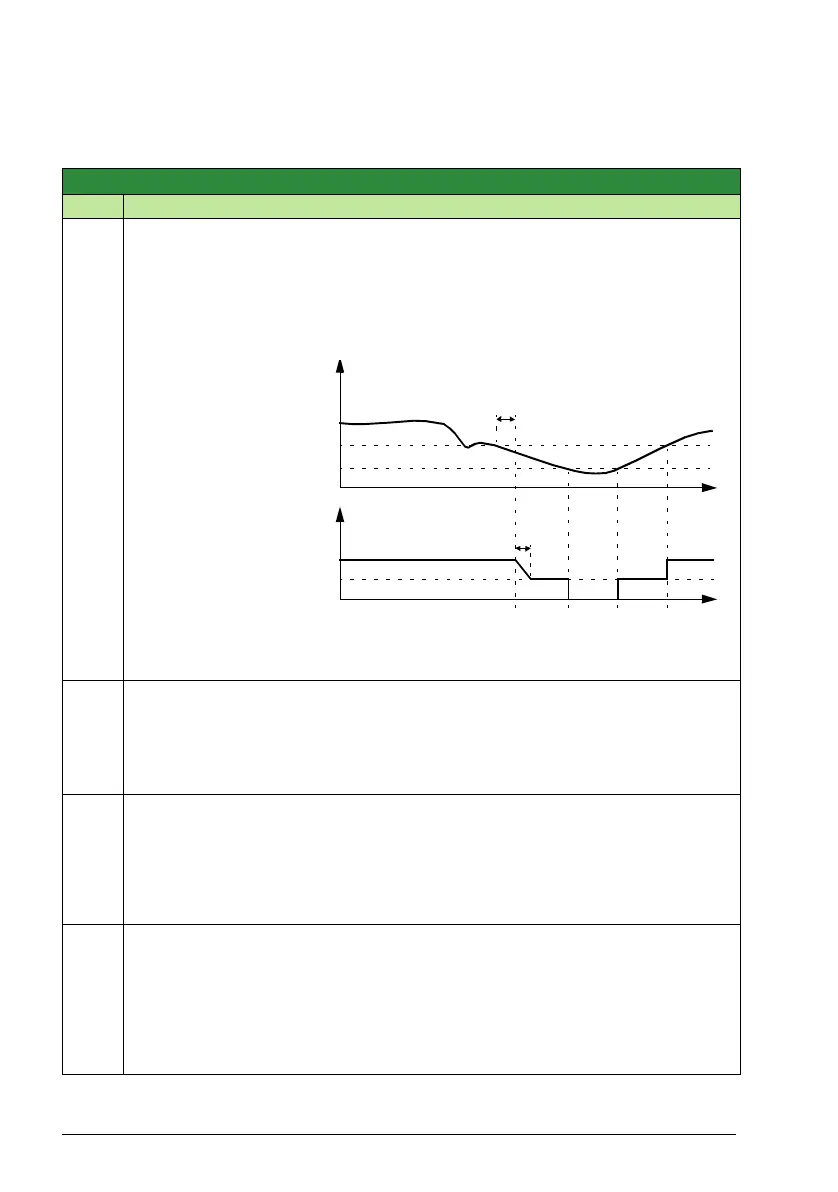

The diagram describes the inlet pressure supervision function.

3 = FAULT – Detection of low inlet pressure trips the drive on a fault.

4402

AI MEASURE INLET

NOT SEL

Selects the analog input for pump/fan inlet pressure supervision.

0 = NOT SEL – No analog input selected.

1 = AI1 – Pump/fan inlet pressure monitored through analog input AI1.

2 = AI2 – See selection AI1.

4403

AI IN LOW LEVEL

0.00 … 100.00% 1 = 0.01% 0.00%

Sets the supervision limit for the primary inlet pressure measurement. If the value of

the selected input falls below this limit, the action defined by parameter 4401 INLET

PROT CTRL is taken after the delay set by parameter 4407 INLET CTRL DLY expires.

The range corresponds to 0…10 V or 0…20 mA on the analog input. With a bipolar

input, the absolute input value is considered.

4404

VERY LOW CTRL

NOT SEL

Enables, and selects the mode of, the secondary inlet pressure supervision function.

The function uses the analog input selected by parameter 4402 AI MEASURE INLET.

0 = NOT SEL – Secondary inlet pressure supervision not used.

1 = STOP – Detection of very low inlet pressure stops the drive. The drive will start

again if the pressure exceeds the supervision level.

2 = FAULT – Detection of very low inlet pressure trips the drive on a fault.

Measured inlet

pressure

PFA reference

(EXT 2)

4403

4405

4407

4408

t

t

4417

Loading...

Loading...