Application macros 93

Dual setpoint with PID

This macro configures for dual setpoint PID applications, where activating digital input

3 (DI3) changes the process PID controller’s setpoint to another value. When using

direct speed reference in AUTO mode or process PID, see section General

considerations on page 80. Set process PID setpoints (internal to the drive) using

parameters 4011 (

SET1) and 4111 (SET2).

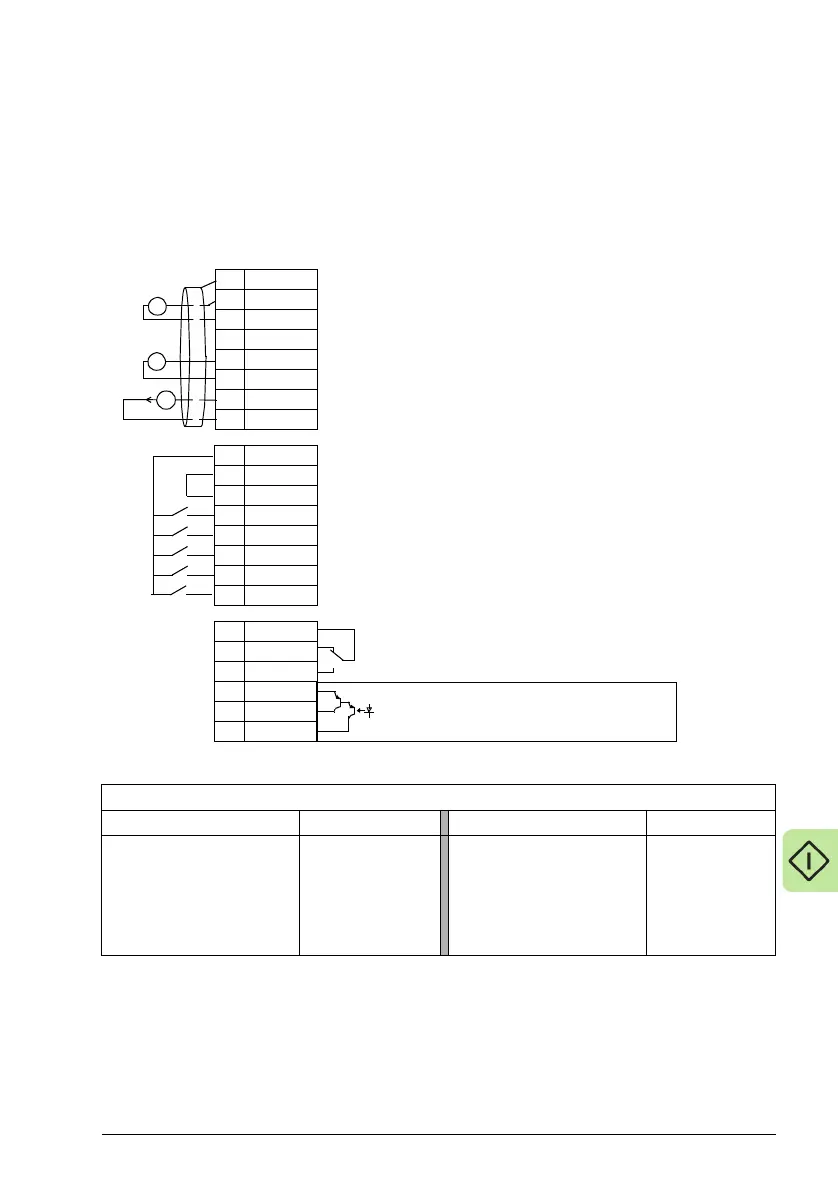

Parameters changed relative to HVAC default

Parameter Value

Parameter Value

9902 APPLIC MACRO 11 (DUAL SETPNT) 4010 SETPOINT SEL 19 (INTERNAL)

1201 CONST SPEED SEL 0 (NOT SEL)

4011 INTERNAL SETPNT 50.0%

1401 RELAY OUTPUT 1 7 (STARTED)

4027 PID 1 PARAM SET 3 (DI3)

1601 RUN ENABLE 2 (DI2)

4110 SETPOINT SEL 19 (INTERNAL)

1609 START ENABLE 2 5 (DI5)

4111 INTERNAL SETPNT 100.0%

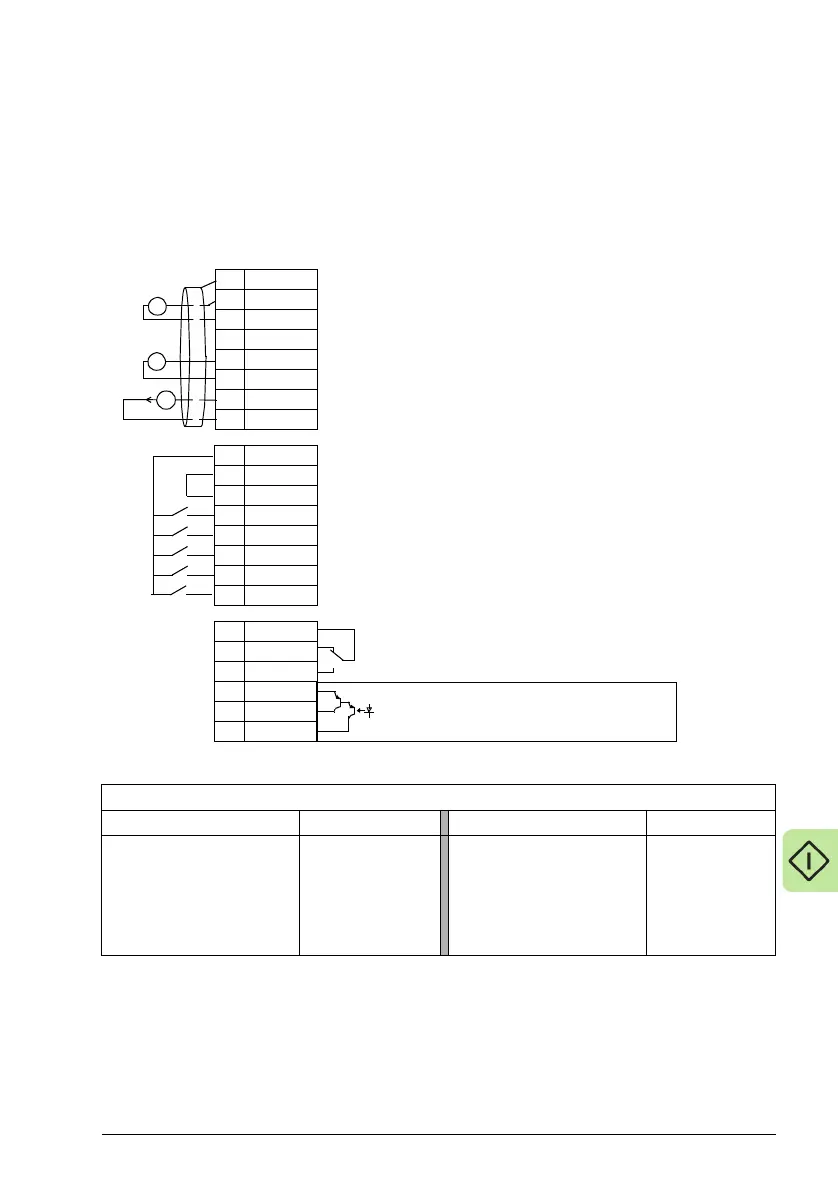

1SCR

2AI1

3AGND

410V

5AI2

6AGND

7AO1

8AGND

924V

10 GND

11 DCOM

12 DI1

13 DI2

14 DI3

15 DI4

16 DI5

17 RO1C

18 RO1A

19 RO1B

20 DOSRC

21 DOOUT

22 DOGND

External reference 0(2)…10 V or 0(4)…20 mA

Reference voltage 10 VDC

Output frequency: 0(4)…20 mA

Start/Stop: Activate to start drive

Run permissive: Deactivate to stop drive (P 1601)

Setpoint Selection: Activate to select Set 2

Safety interlock1: Deactivate to stop drive (P 1608)

Safety interlock2: Deactivate to stop drive (P 1609)

Relay output 1 (P 1401)

Default operation: Started =>17 connected to 19

Digital output, max. 100 mA (P 1805)

No fault [Fault(-1)] =>20 connected to 22

X1A

Analog input circuit common

PID feedback: 0(2)…10 V or 0(4)…20 mA

Analog output circuit common

Auxiliary voltage output +24 VDC

Auxiliary voltage output common

Digital input common for all

Signal cable shield (screen)

Analog input circuit common

+

mA

+

X1B

Loading...

Loading...