298 Fieldbus control

Actual value scaling

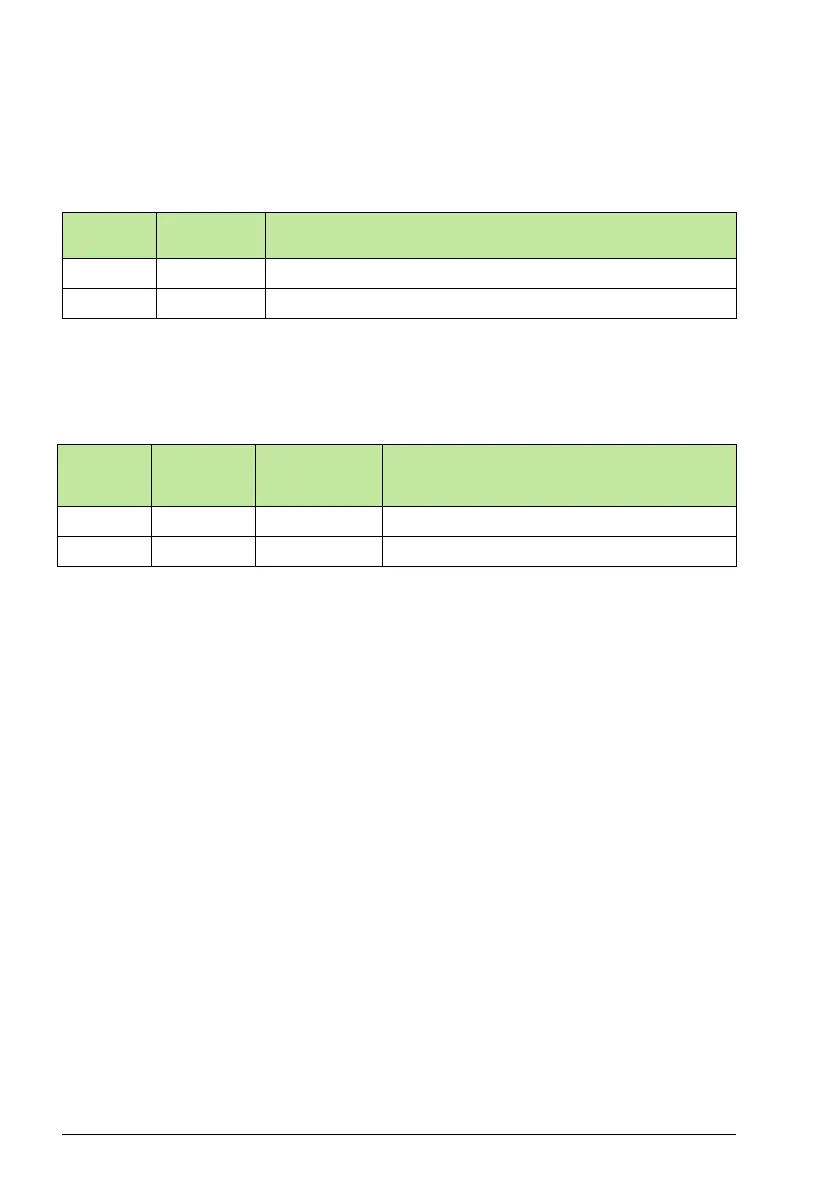

The scaling of actual values can be protocol dependent. In general, for Actual values,

scale the feedback integer using the parameter’s resolution. (See section Parameter

listing for parameter resolutions.) For example:

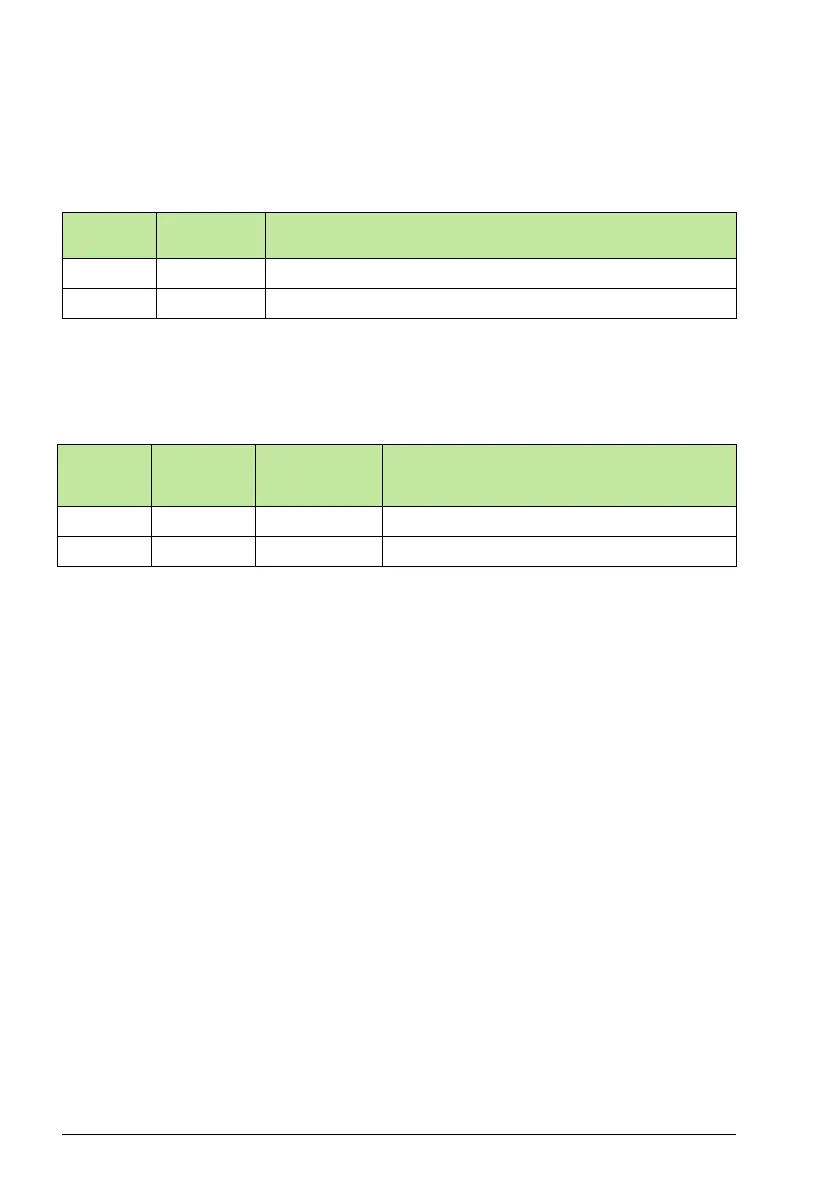

Where parameters are in percent, section Parameter listing specifies what parameter

corresponds to 100%. In such cases, to convert from percent to engineering units,

multiply by the value of the parameter that defines 100% and divide by 100%. For

example:

1. Assuming, for the sake of this example, that the Actual value uses parameter 9908 MOTOR NOM SPEED

as the 100% reference, and that 9908 = 1800 rpm.

2. Assuming, for the sake of this example, that the Actual value uses parameter 9907 MOTOR NOM FREQ as

the 100% reference, and that 9907 = 6.00 Hz.

Although Actual value scaling could differ from the above for the N2 and FLN

protocols, it currently does not. To confirm, see the following sections, as appropriate:

• N2 analog input objects in the N2 protocol technical data section.

• Scaling drive feedback values in the FLN protocol technical data section.

Scaling does not apply for the BACnet protocol.

Feedback

Integer

Parameter

Resolution

(Feedback Integer) * (Parameter Resolution) = Scaled Value

1 0.1 mA 1 * 0.1 mA = 0.1 mA

10 0.1% 10 * 0.1% = 1%

Feedback

Integer

Parameter

Resolution

Value of the

Parameter that

defines 100%

(Feedback Integer) * (Parameter Resolution)

* (Value of 100% Ref.) / 100% = Scaled Value

10 0.1% 1800 rpm

1

10 * 0.1% * 1800 RPM / 100% = 18 rpm

100 0.1% 600 Hz

2

100 * 0.1% * 600 Hz / 100% = 60 Hz

Loading...

Loading...