5-7

5 Maintenance and Abnormality Handling

NB-series Programmable Terminals NB-Designer Operation Manual(V106)

5-3 Abnormality Handling

5

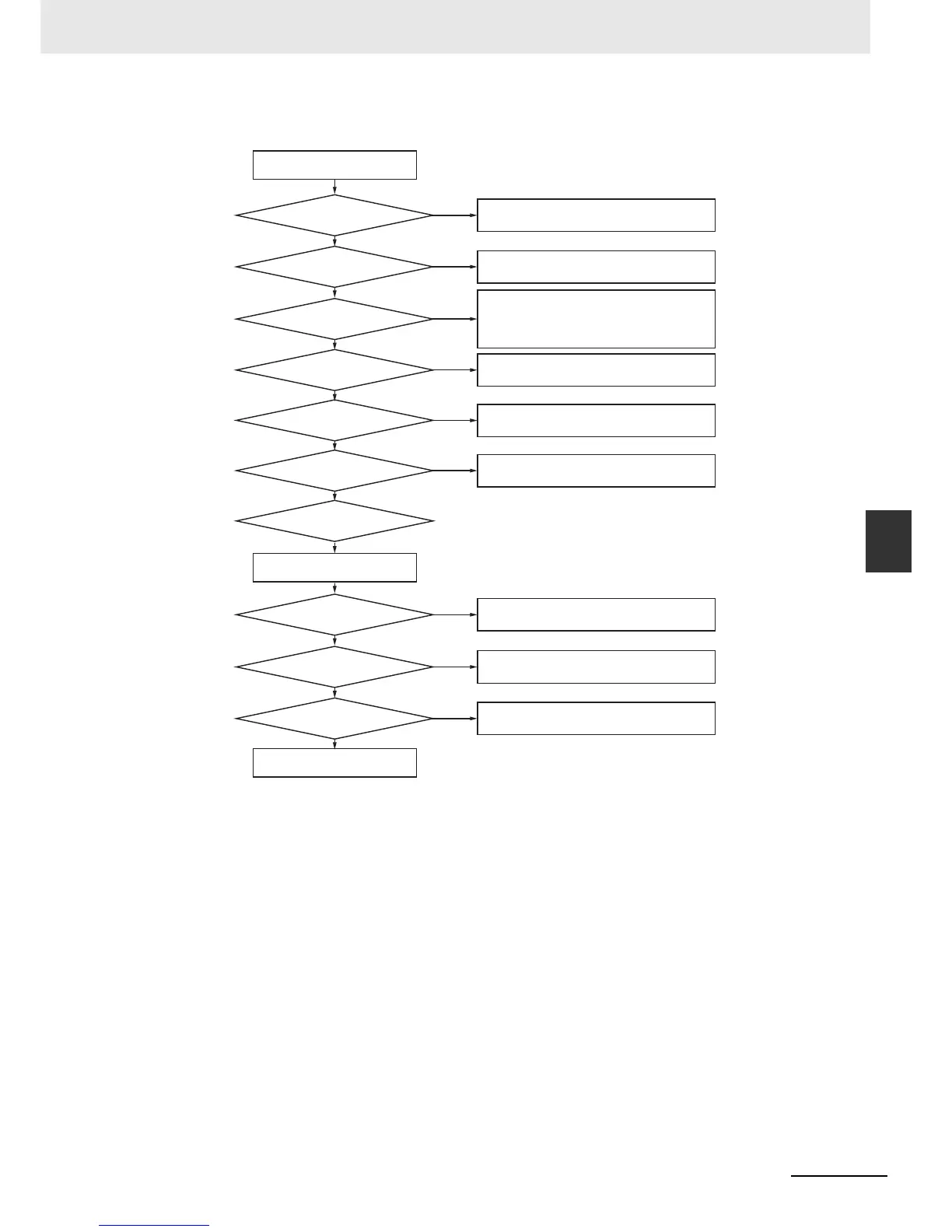

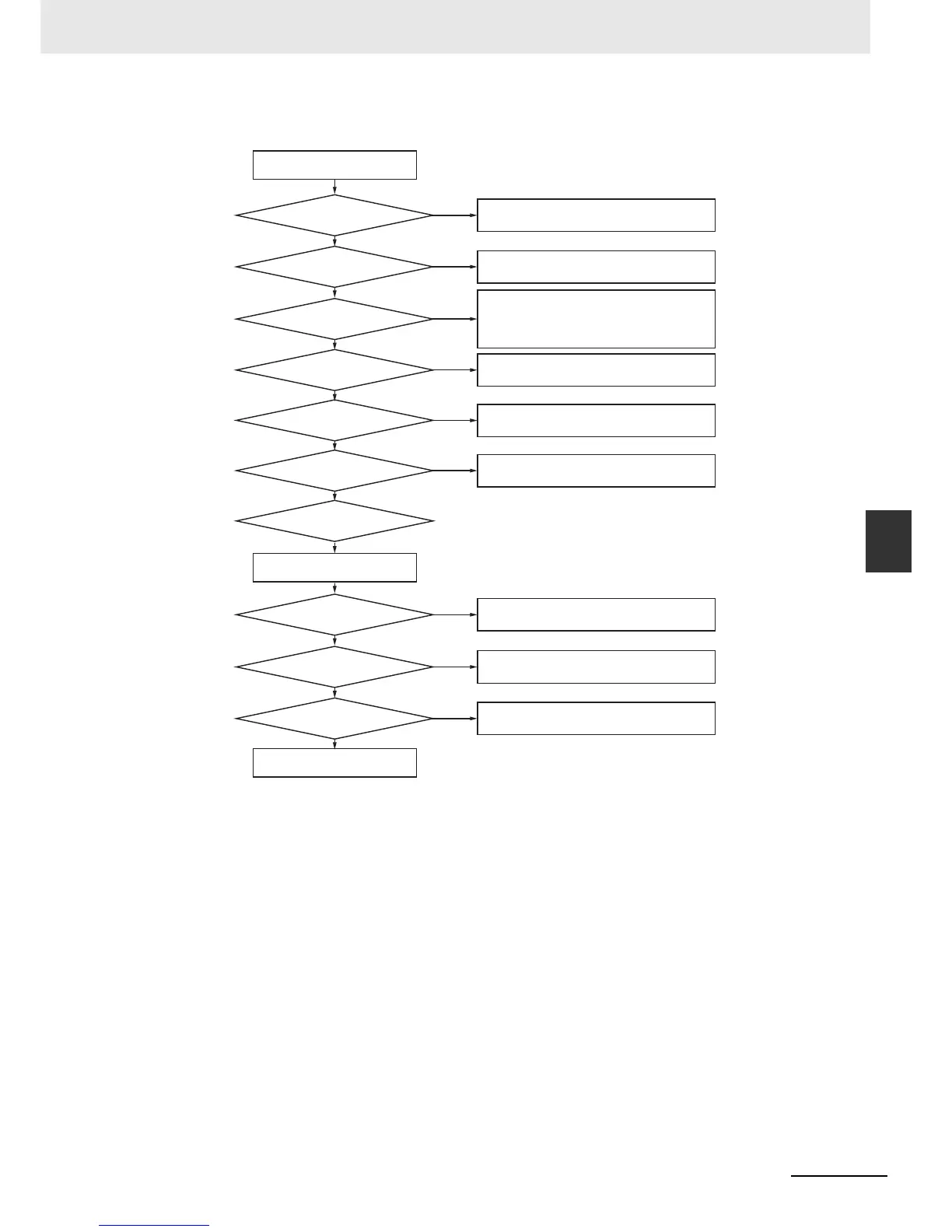

Solutions for “PLC no response” and “PLC response error”

When compile error occurs

In the Output Window, you can see the error number and error reason such as:

Address error for Parts or over-limit.

PLC no response

Refer to [Appendix-4 Fabrication of the Connec-

tion Cable] in NB series Setup Manual.

Refer to [Appendix-4 Fabrication of the Connec-

tion Cable] in NB series Setup Manual.

Check whether the baud rate, parity bit, data bit,

stop bit are correct or not, the communication type

is RS232 or RS485?

Refer to [Appendix-4 Fabrication of the Connection

Cable] in NB series Setup Manual.

Check whether the cable is

wired correctly or not.

Check whether the communi-

cation setting is correct or not.

Check whether PLC station

no. is correct or not.

Check whether the PLC area

and range are correct or not.

Check whether the PLC address

supports the write operation.

Please contact with

OMRON service center.

Check whether the type and settings

of the PLC are correct or not.

Check whether the PLC area

and range are correct or not.

Check whether the PLC address

supports the write operation.

Check the arrangement of 9-pin

RS-232C female socket port.

PLC response error

Ye s

NO

Ye s

Ye s

Ye s

Ye s

Ye s

Ye s

Ye s

Ye s

Ye s

Check if the PLC Type used currently and the

one for the PLC on the project are correct.

NO

NO

NO

NO

NO

NO

NO

NO

Check the content of the variable table.

Refer to the relevant PLC document.

Check if the PLC Type used currently and the

one for the PLC on the project are correct.

Check the content of the Variable Table.

Refer to the relevant PLC document.

Check whether the type and settings

of the PLC are correct or not.

Loading...

Loading...