Note

The cycle is provided with new functions that are not on earlier software versions.

Consequently certain parameters in the screen form (<NUM>, <RAD>, <INDA>) are no

longer displayed. Multiple slots on one position pattern can be programmed using "MCALL"

and calling the desired position pattern, e.g. HOLES2.

3.25.1.8 SLOT2 - circumferential slot

Syntax

SLOT2(<RTP>, <RFP>, <SDIS>, <_DP>, <_DPR>, <NUM>, <AFSL>, <WID>,

<_CPA>, <_CPO>, <RAD>, <STA1>, <INDA>, <FFD>, <FFP1>, <_MID>,

<CDIR>, <_FAL>, <VARI>, <_MIDF>, <FFP2>, <SSF>, <_FFCP>, <_UMODE>,

<_FS>, <_ZFS>, <_GMODE>, <_DMODE>, <_AMODE>)

Parameters

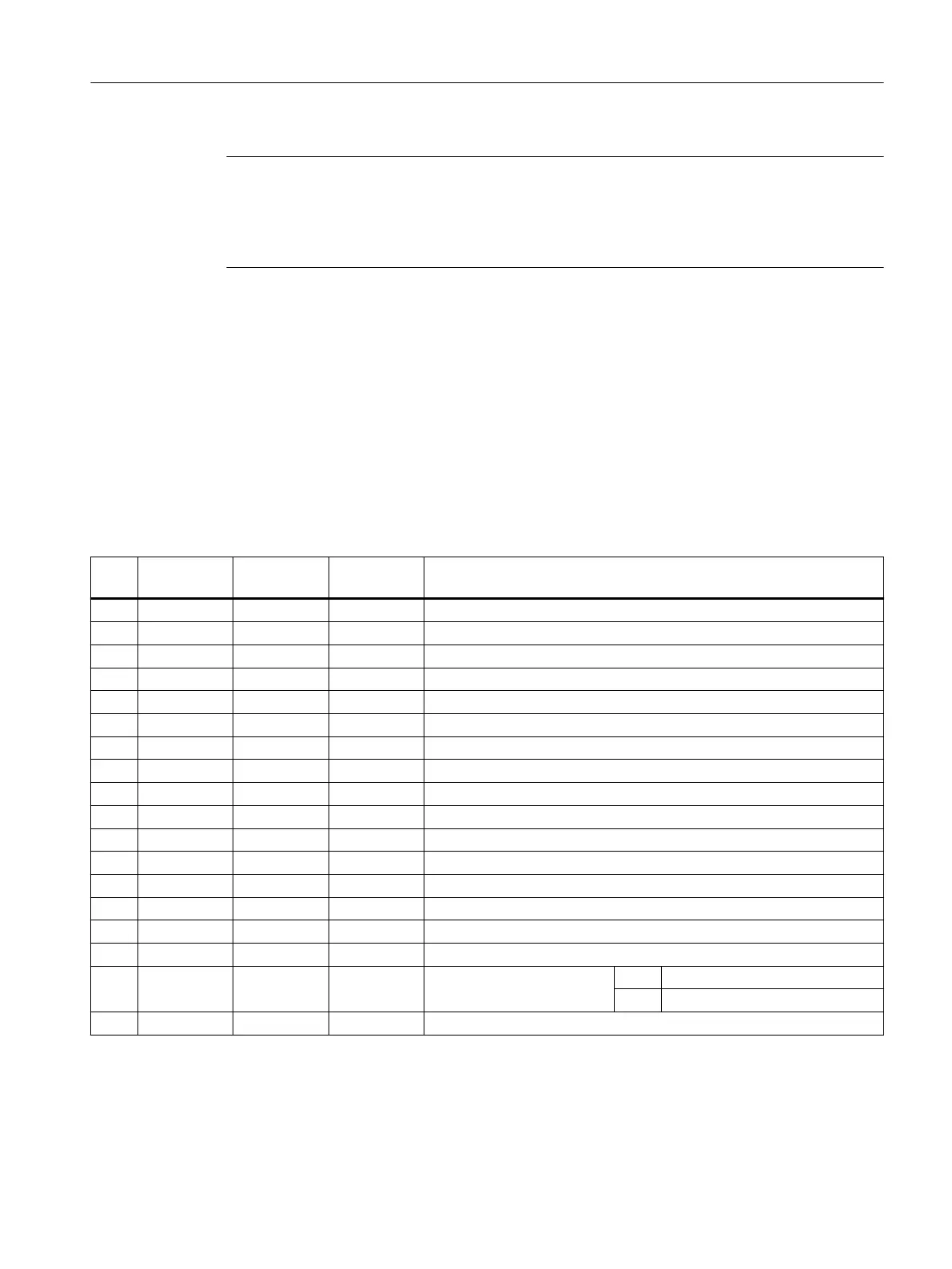

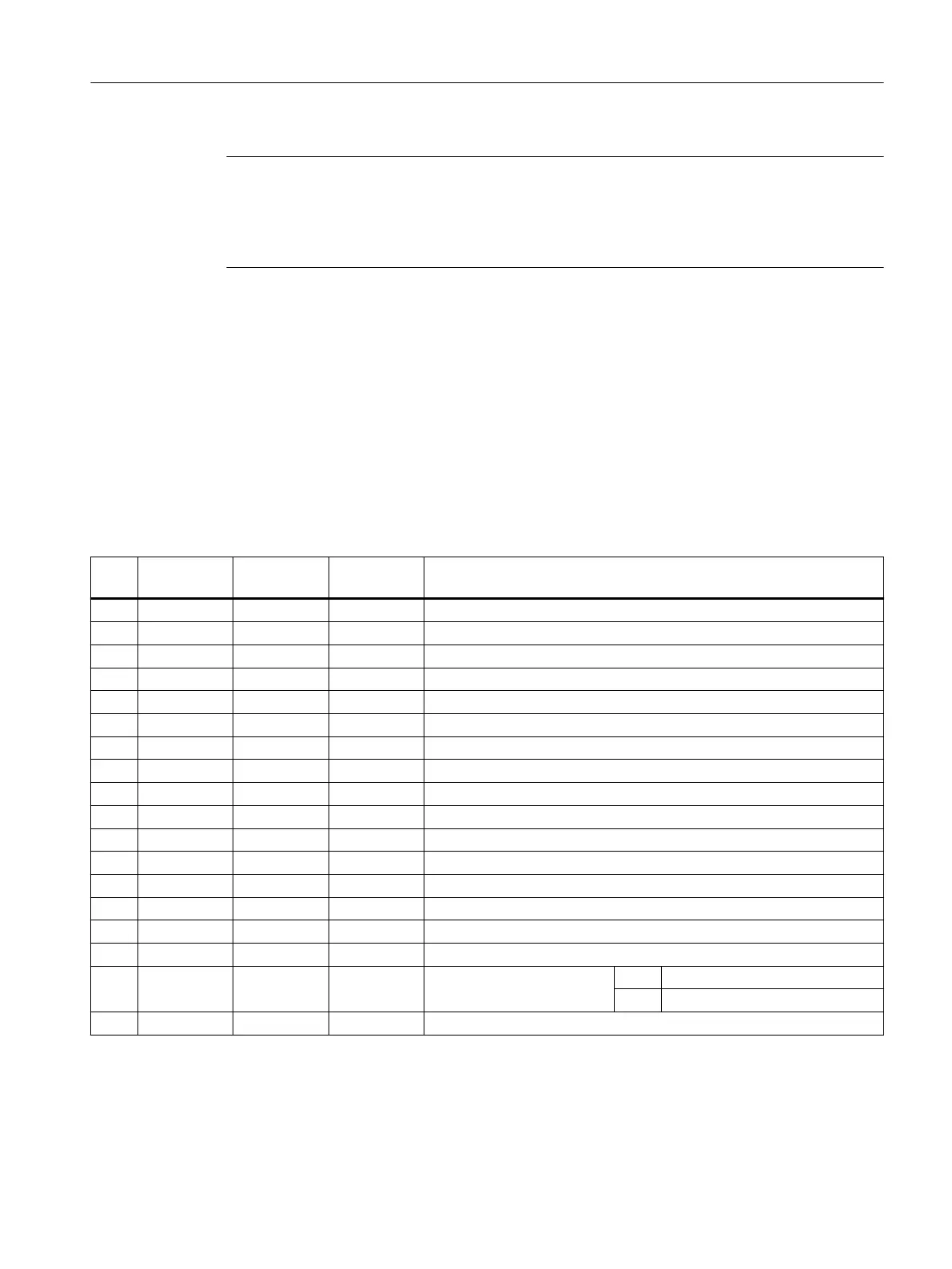

No. Parameter

mask

Parameter

internal

Data type Meaning

1 RP <RTP> REAL Retraction plane (abs)

2 Z0 <RFP> REAL Reference point of tool axis (abs)

3 SC <SDIS> REAL Safety clearance (to be added to reference point, enter without sign)

4 Z1 <_DP> REAL Slot depth (abs)

5 <_DPR> REAL Slot depth (inc) with respect to Z0 (enter without sign)

6 N <NUM> INT Number of slots

7 α1 <AFSL> REAL Opening angle of the slot

8 W <WID> REAL Slot width

9 X0 <_CPA> REAL Reference point = Center point of circle, 1st axis of the plane

10 Y0 <_CPO> REAL Reference point = Center point of circle, 2nd axis of the plane

11 R <RAD> REAL Radius of the circle

12 α0 <STA1> REAL Starting angle

13 α2 <INDA> REAL Incrementing angle

14 FZ <FFD> REAL Depth infeed rate

15 F <FFP1> REAL Feedrate

16 DZ <_MID> REAL Maximum depth infeed

17 <CDIR> INT Milling direction 0 = Down-cut

1 = Up-cut

18 UXY <_FAL> REAL Finishing allowance on plane or slot edge

Work preparation

3.25 Programming cycles externally

NC programming

Programming Manual, 12/2019, 6FC5398-2EP40-0BA0 1037

Loading...

Loading...