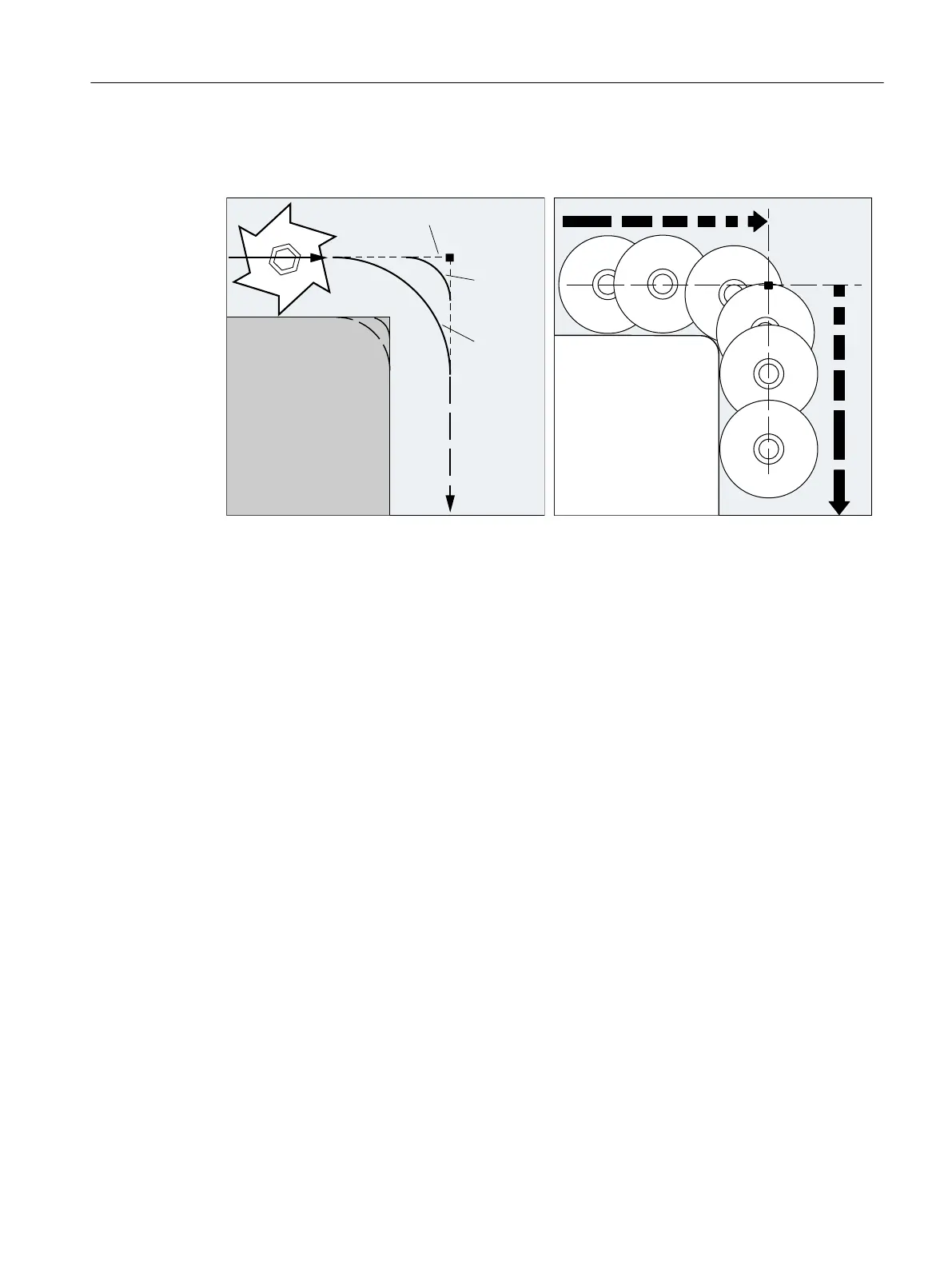

dynamic response of the axes and the path velocity. The workpiece corners can now be

rounded.

3URJUDPPHGSDWK

WUDYHUVHG

3DWK

ZLWK)

WUDYHUVHG

3DWK

ZLWK)

))

Configured exact stop criterion

A channel-specific setting can be made for G0 and the other commands in the 1st G group

indicating that contrary to the programmed exact stop criterion, a preset criterion should be

used automatically (see the machine manufacturer's specifications).

2.11.2 Continuous-path mode (G64, G641, G642, G643, G644, G645, ADIS, ADISPOS)

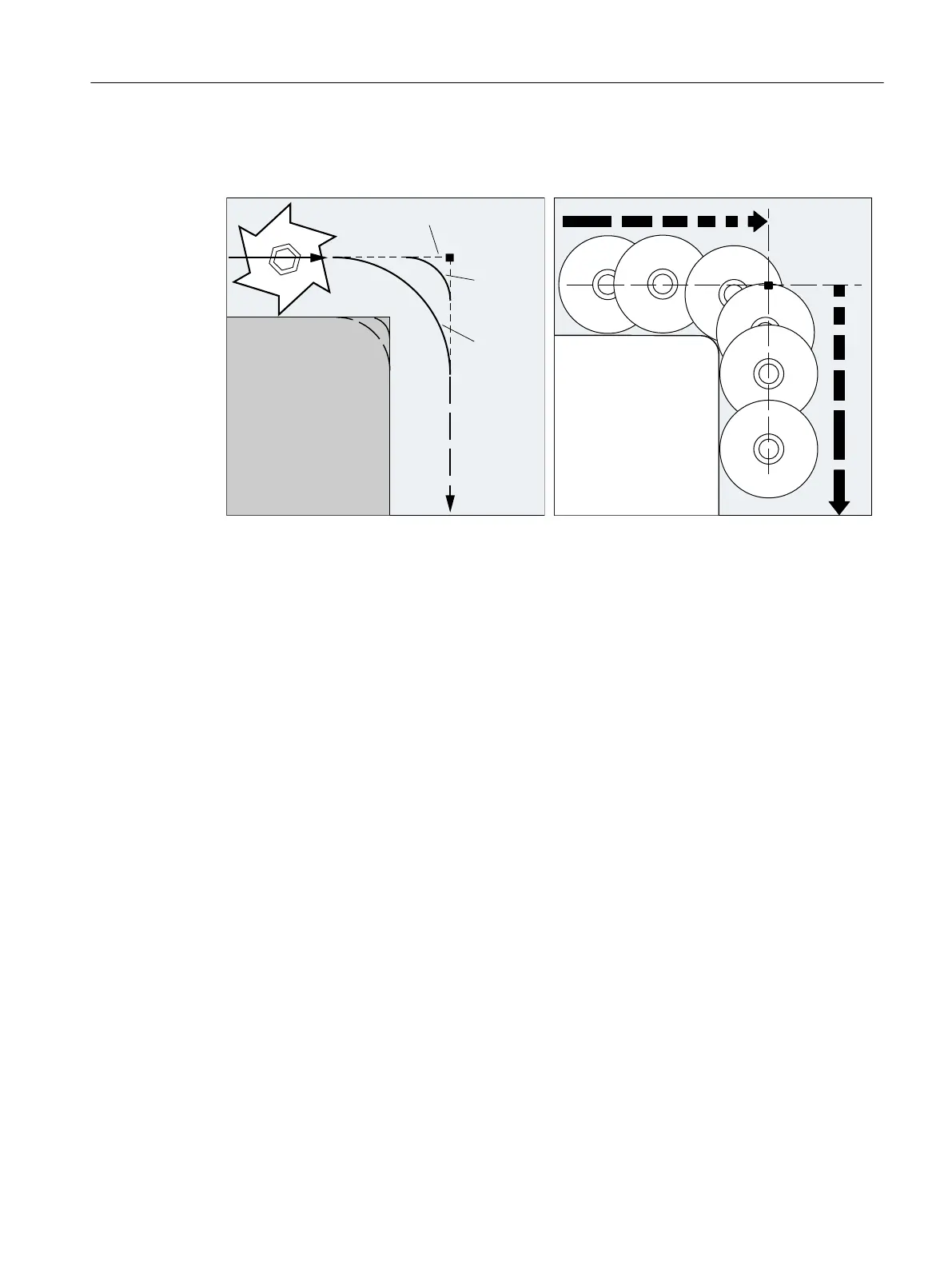

In continuous-path mode, the path velocity at the end of the block (for the block change) is not

decelerated to a level which would permit the fulfillment of an exact stop criterion. The objective

of this mode is, in fact, to avoid rapid deceleration of the path axes at the block-change point so

that the axis velocity remains as constant as possible when the program moves to the next

block. To achieve this objective, the "Look-head" function is also activated when continuous-

path mode is selected.

Continuous-path mode with smoothing facilitates the tangential shaping and/or smoothing of

angular block transitions caused by local changes in the programmed contour.

Continuous path mode:

● Rounds the contour

● Reduces machining times by eliminating braking and acceleration processes that are

required to fulfill the exact-stop criterion

● Improves cutting conditions because of the more constant velocity

Continuous-path mode is suitable if:

● A contour needs to be traversed as quickly as possible (e.g. with rapid traverse)

● The exact contour may deviate from the programmed contour within a specific tolerance for

the purpose of obtaining a continuous contour

Fundamentals

2.11 Path action

NC programming

Programming Manual, 12/2019, 6FC5398-2EP40-0BA0 295

Loading...

Loading...