3. Create a machining plan

Define all machining operations step-by-step, e.g.

– Rapid traverse movements for positioning

– Tool change

– Define the machining plane

– Retraction for checking

– Switch spindle, coolant on/off

– Call up tool data

– Feed

– Path correction

– Approaching the contour

– Retraction from the contour

– etc.

4. Compile machining steps in the programming language

– Write each individual step as an NC block (or NC blocks).

5. Combine the individual steps into a program

2.3.2 Available characters

The following characters are available for writing NC programs:

● Uppercase characters:

A, B, C, D, E, F, G, H, I, J, K, L, M, N,(O),P, Q, R, S, T, U, V, W, X, Y, Z

● Lowercase characters:

a, b, c, d, e, f, g, h, i, j, k, l, m, n, o, p, q, r, s, t, u, v, w, x, y, z

● Numbers:

0, 1, 2, 3, 4, 5, 6, 7, 8, 9

● Special characters:

See the table below.

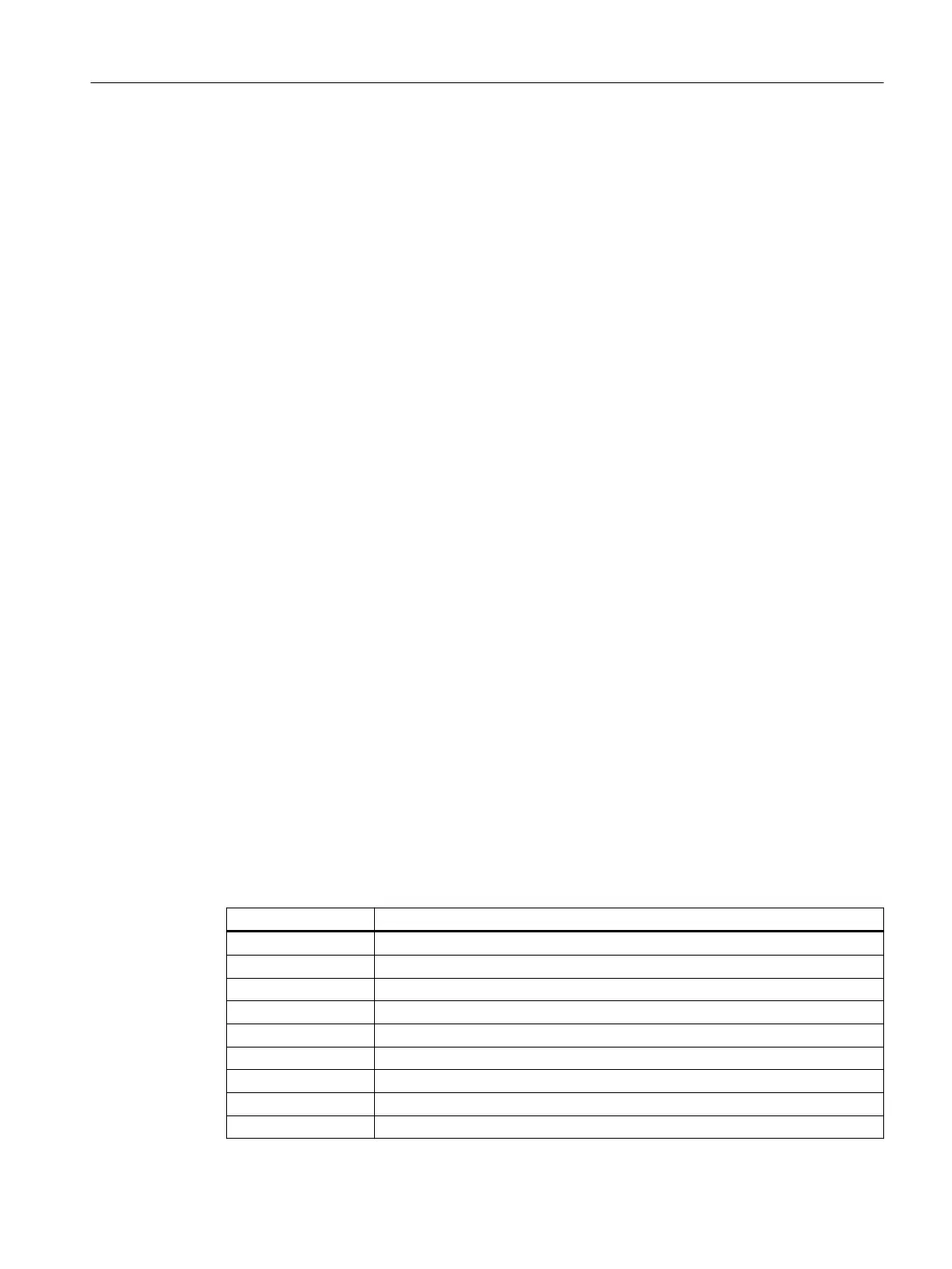

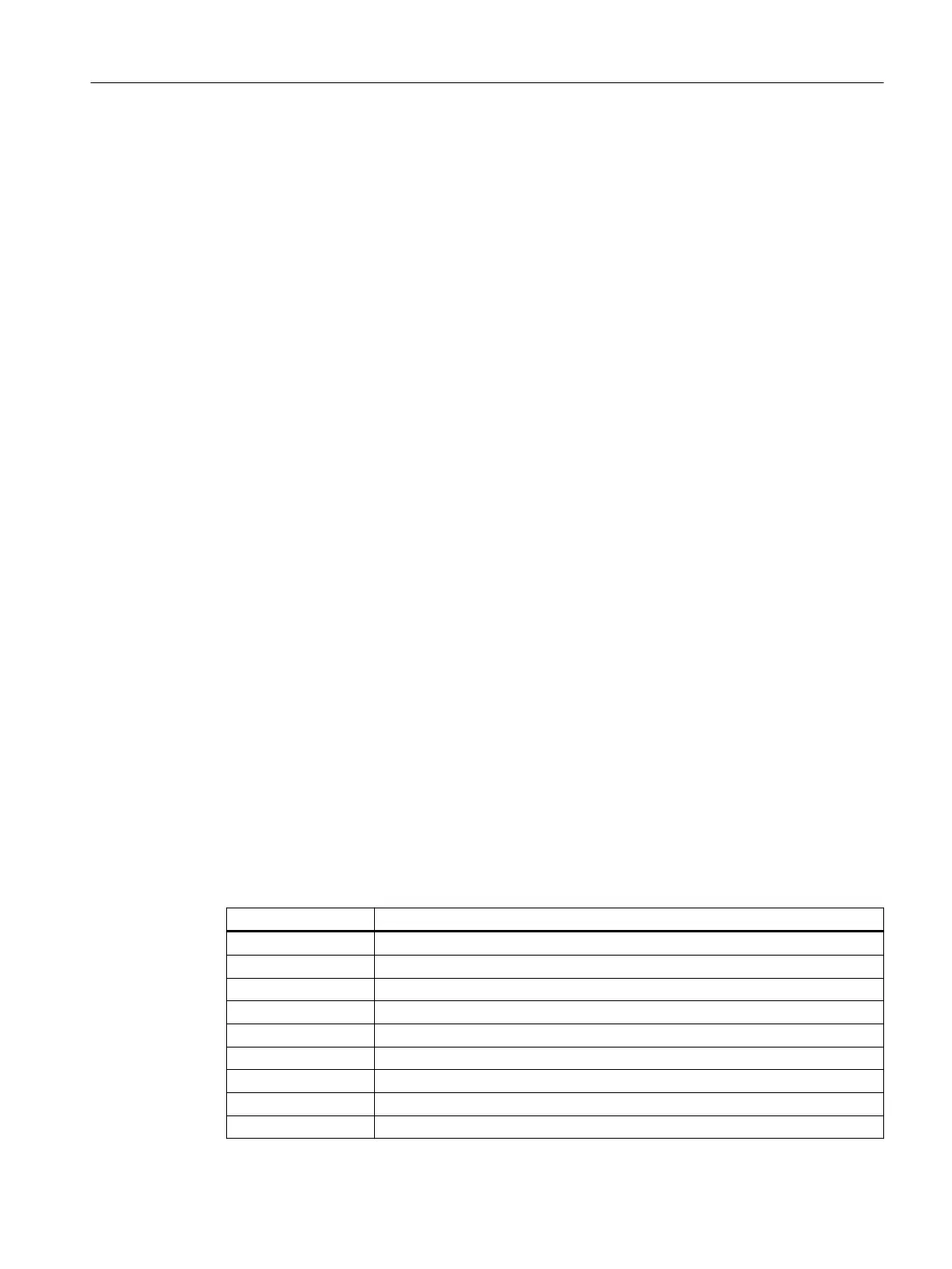

Special characters Meaning

% Program start character (used only for writing programs on an external PC)

( For bracketing parameters or expressions

) For bracketing parameters or expressions

[ For bracketing addresses or indexes

] For bracketing addresses or indexes

< Less than

> Greater than

: Main block, end of label, chain operator

= Assignment, part of equation

Fundamentals

2.3 Creating an NC program

NC programming

Programming Manual, 12/2019, 6FC5398-2EP40-0BA0 51

Loading...

Loading...