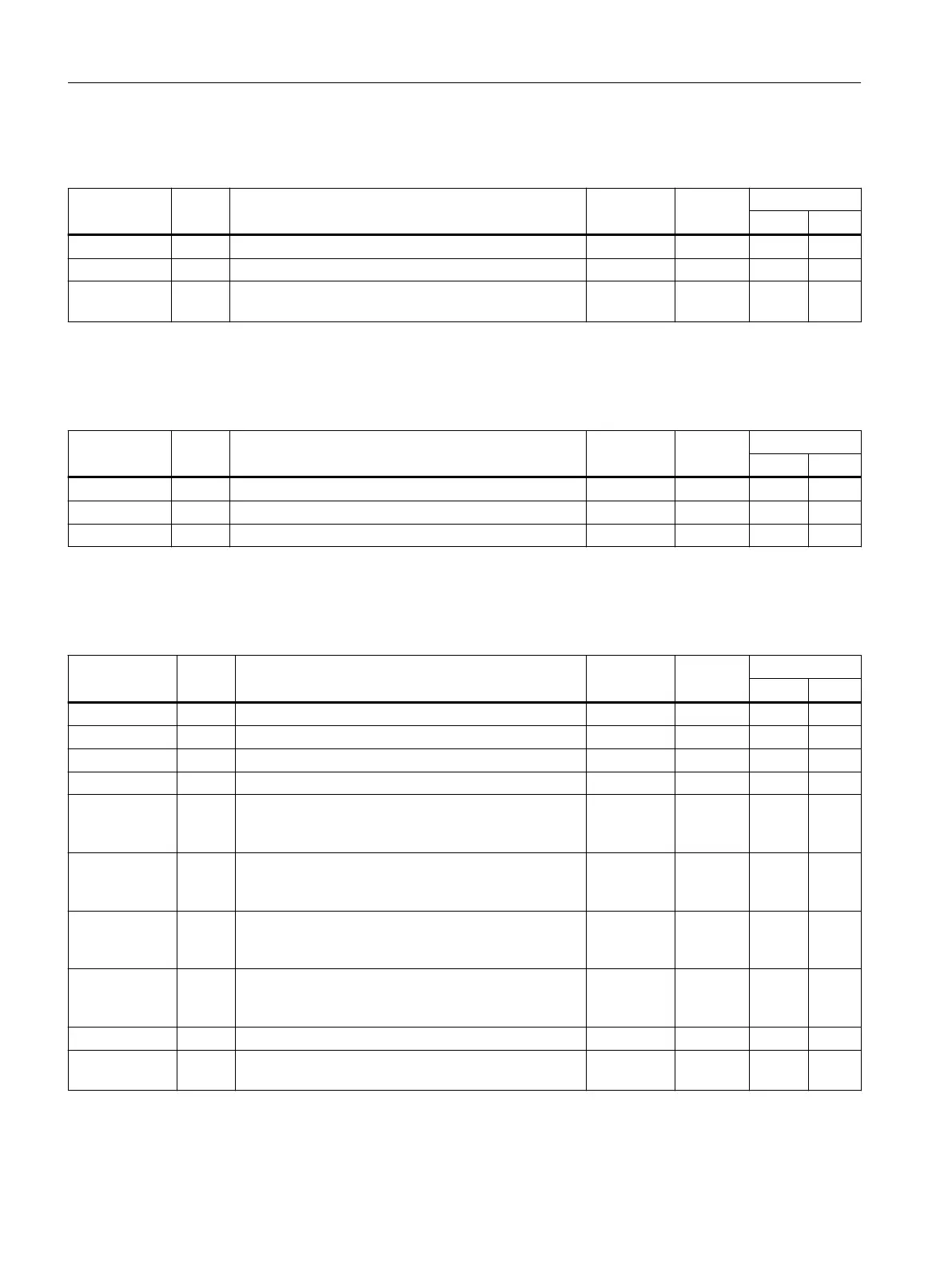

4.3.20 G group 20: Curve transition at end of spline

G command No.

1)

Meaning MD20150

2)

W

3)

STD

4)

SAG MH

ENAT 1 Natural transition to next traversing block + m x

ETAN 2 Tangential transition to next traversing block + m

EAUTO 3 Definition of the last spline section by means of the last

3 points

+ m

4.3.21 G group 21: Acceleration profile

G command No.

1)

Meaning MD20150

2)

W

3)

STD

4)

SAG MH

BRISK 1 Fast non-smoothed path acceleration + m x

SOFT 2 Soft smoothed path acceleration + m

DRIVE 3 Velocity-dependent path acceleration + m

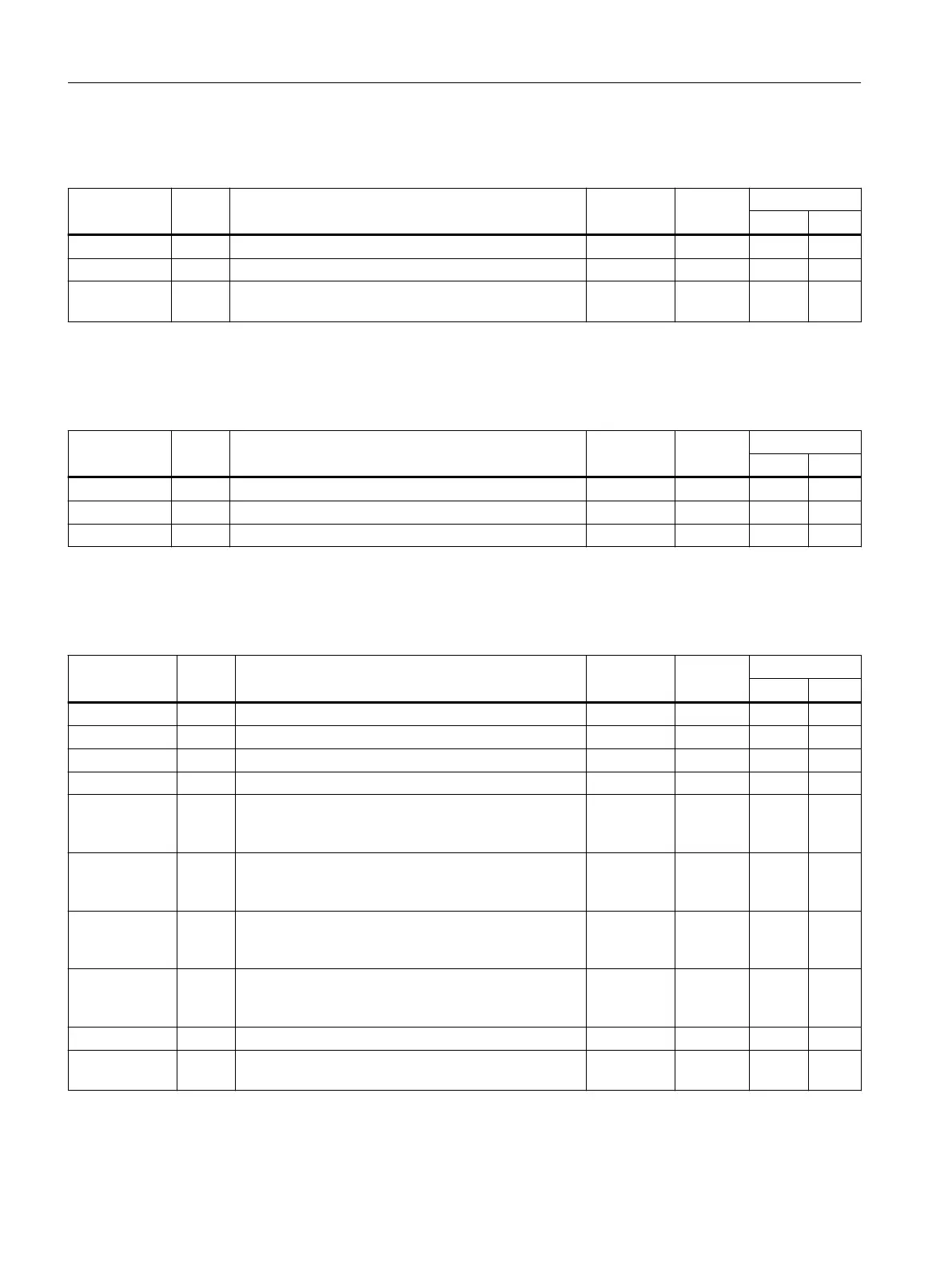

4.3.22 G group 22: Tool offset type

G command No.

1)

Meaning MD20150

2)

W

3)

STD

4)

SAG MH

CUT2D 1 2½D TRC + m x

CUT2DF 2 2½D TRC relative to the current frame (inclined plane) + m

CUT3DC 3 3D TRC for circumferential milling + m

CUT3DF 4 3D TRC for face milling with change in orientation + m

CUT3DFS 5 3D TRC for face milling with constant orientation. The

tool orientation is defined by G17 - G19 and is not

influenced by frames.

+ m

CUT3DFF 6 3D TRC for face milling with constant orientation. The

tool orientation is the direction defined by G17 - G19

and, in some cases, rotated by a frame.

+ m

CUT3DCC 7 3D TRC for circumferential milling taking into account

a limitation surface with 3D radius compensation: Con‐

tour on the machining surface

+ m

CUT3DCCD 8 3D TRC for circumferential milling taking into account

a limitation surface with a differential tool on the tool

center-point path: Infeed to the limitation surface

+ m

CUT2DD 9 2½ D TRC in relation to the differential tool + m

CUT2DFD 10 2½D TRC in relation to a differential tool relative to the

current frame (inclined plane)

+ m

Tables

4.3 G commands

NC programming

1254 Programming Manual, 12/2019, 6FC5398-2EP40-0BA0

Loading...

Loading...