● 1 second sparking-out time

● Standard geometry axes

Program code

N10 T1 D1

N20 CYCLE4075(0.02,0.01,1,100,1,1000,1)

N30 M30

3.25.1.50 CYCLE4077 - surface grinding with infeed at the reversal point and cancel signal

Syntax

CYCLE4077(<S_GAUGE>, <S_I>, <S_J>, <S_K>, <S_A>, <S_R>, <S_F>,

<S_P>, <S_A1>, <S_A2>)

Parameters

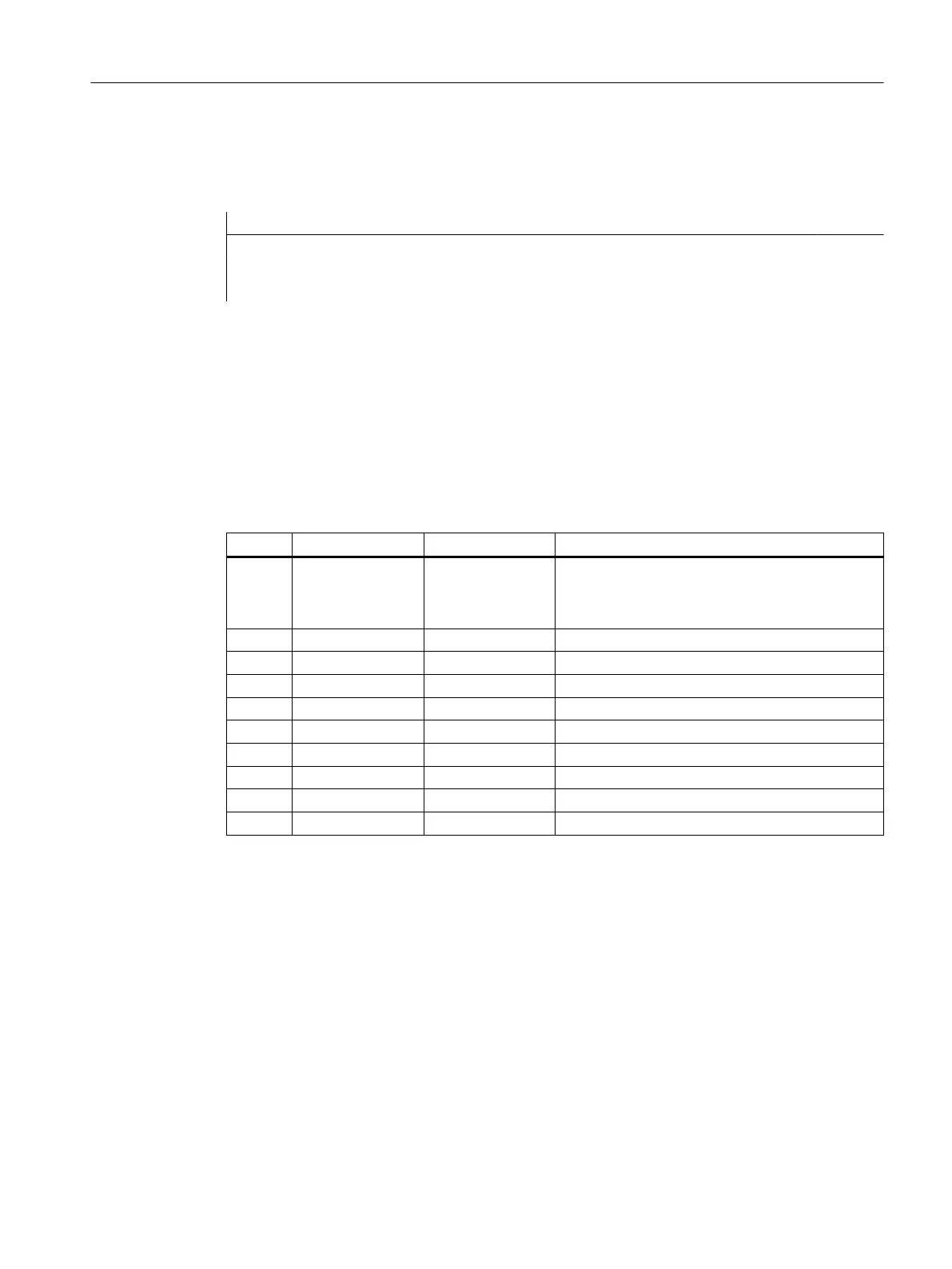

No. Parameter Data type Meaning

1 <S_GAUGE> STRING Cancel condition for infeed:

● Number of a rapid input

● Logical expression

2 <S_I> REAL Infeed depth at the start

3 <S_J> REAL Infeed depth at the end

4 <S_K> REAL Total infeed depth

5 <S_A> REAL Grinding width

6 <S_R> REAL Feedrate for infeed

7 <S_F> REAL Feedrate for transverse infeed

8 <S_P> REAL Sparking-out time

9 <S_A1> AXIS Infeed axis (optional)

10 <S_A2> AXIS Oscillating axis (optional)

Function

The cycle is used for machining with a total infeed depth in infeed steps. The infeed depths at

the start and at the end can be different. There is a tangential motion between the infeeds. The

depth infeed is cancelled when the cancel signal of the rapid input is 1 or the cancel condition

is satisfied. A complete stroke is performed after the cancellation.

The positional data P2 to P5 can be negative or positive.

The specification of the infeed axis and/or oscillating axis is optional. If one or both parameters

are not specified, the cycle uses the first two geometry axes of the channel.

If the sum of the infeed depth at the start and end is 0 or the total infeed depth is 0, only one

sparking-out stroke is performed.

Work preparation

3.25 Programming cycles externally

NC programming

Programming Manual, 12/2019, 6FC5398-2EP40-0BA0 1143

Loading...

Loading...