3.25.3.2 CYCLE974 measuring cycle parameters

PROC CYCLE974(INT S_MVAR,INT S_KNUM,INT S_KNUM1,INT S_PRNUM,REAL S_SETV,INT S_MA,REAL

S_FA,REAL S_TSA,REAL S_STA1,INT S_NMSP,STRING[32] S_TNAME,INT S_DLNUM,REAL S_TZL,REAL

S_TDIF,REAL S_TUL,REAL S_TLL,REAL S_TMV,INT S_K,INT S_EVNUM,INT S_MCBIT,INT _DMODE,INT

_AMODE,INT _DP)

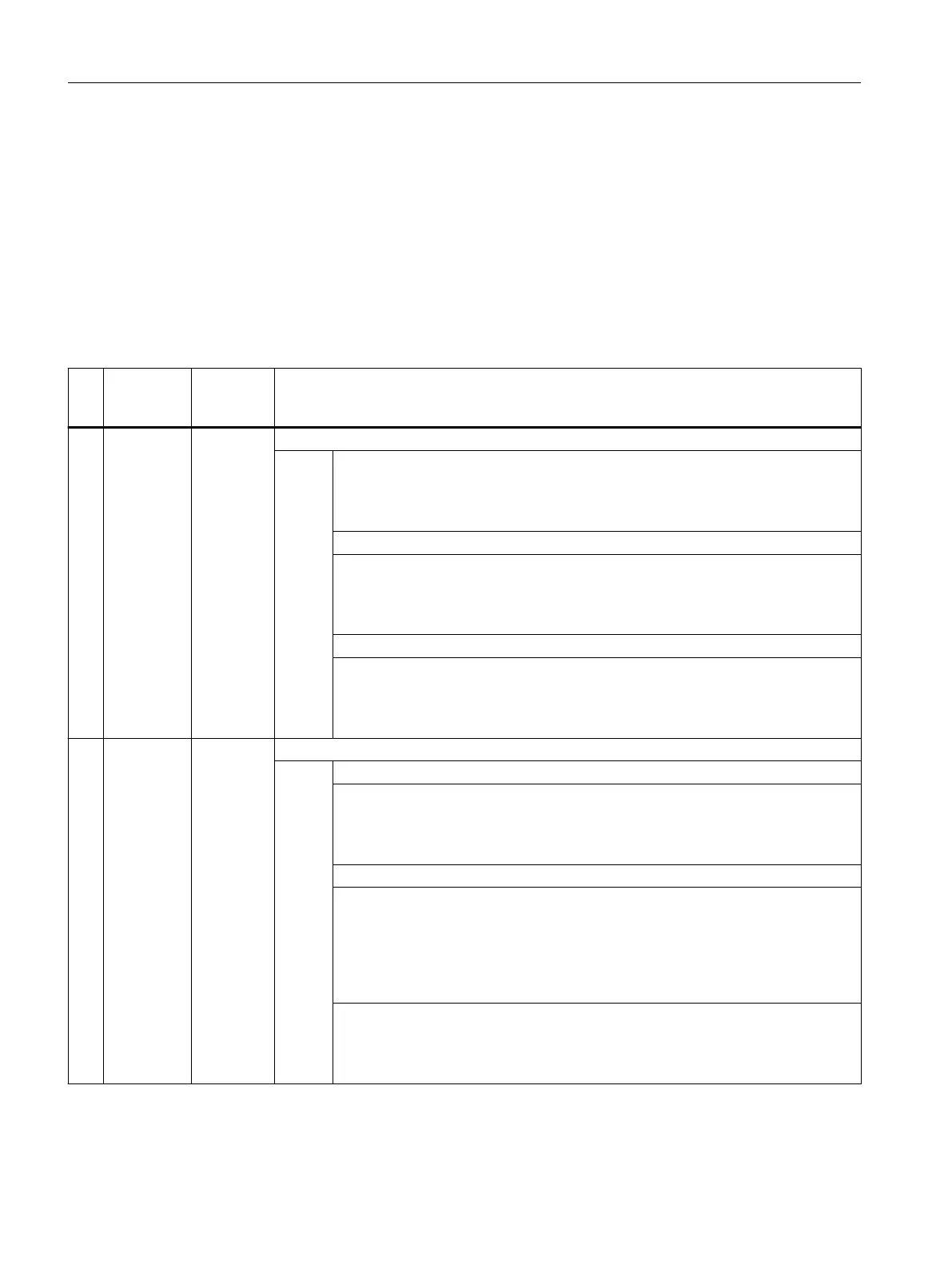

Table 3-9 CYCLE974 call parameters

1)

No. Screen

form pa‐

rameter

Cycle pa‐

rameter

Meaning

1 S_MVAR Measuring variant

Val‐

ues:

UNITS:

0 = Measure front face

1 = Inside measurement

2 = Outside measurement

TENS: Reserved

HUNDREDS: Correction target

0 = Only measurement (no correction of the WO or no tool offset)

1 = Measurement, determination and correction of the WO (see S_KNUM)

3)

2 = Measurement and tool offset (see S_KNUM1)

THOUSANDS: Reserved

TEN THOUSANDS: Measurement with or without reversal of the main spindle

(turning spindle)

0 = Measurement without reversal

1 = Measurement with reversal

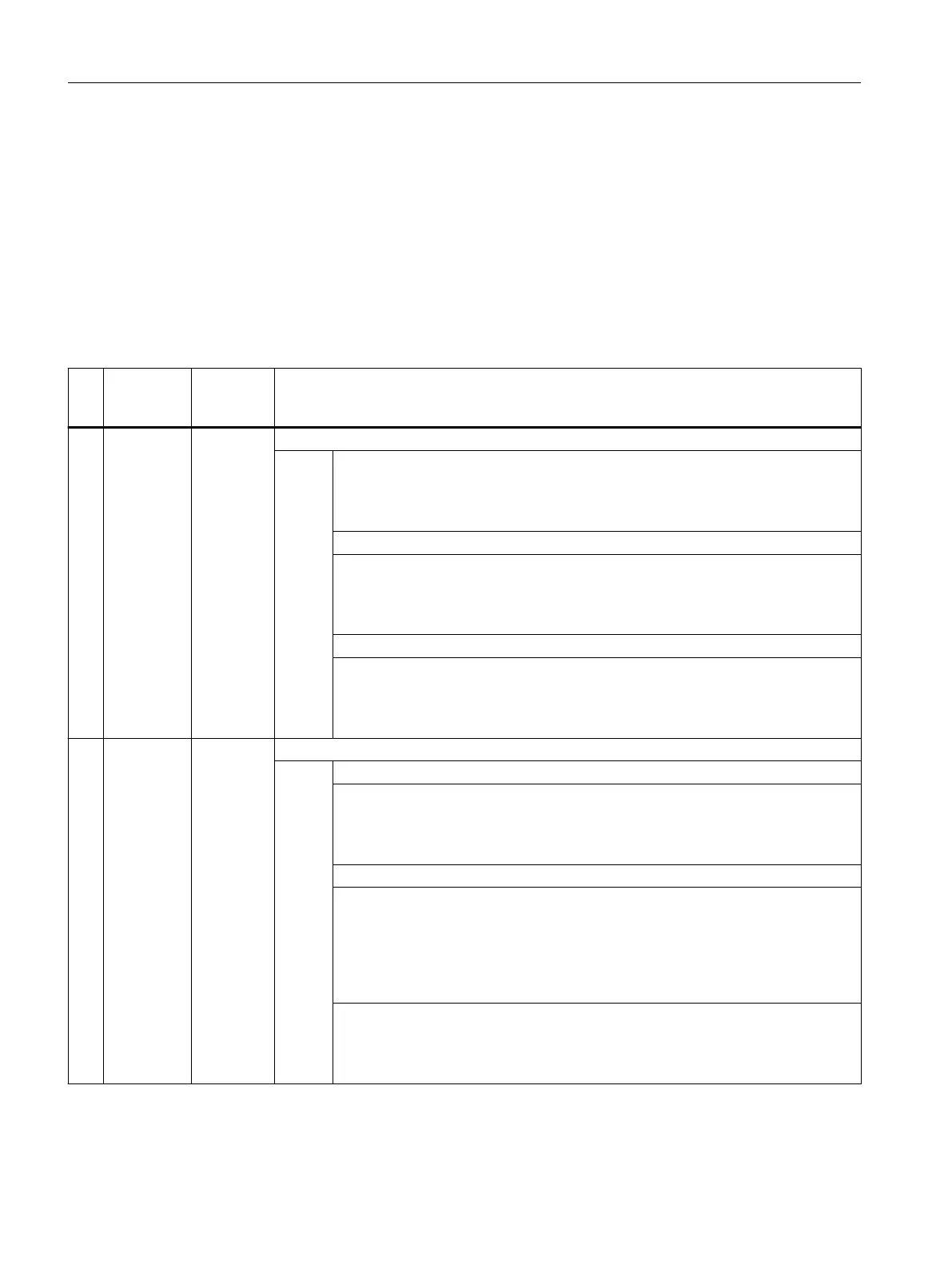

2 Selection S_KNUM Correction in work offset (WO) or basic WO or basic reference

2)

Val‐

ues:

UNITS:

TENS:

0 = No correction

1 to max. 99 numbers of the work offset or

1 to max. 16 numbers of the basic offset

HUNDREDS: Reserved

THOUSANDS: Correction in WO or basic WO or basic reference

0 = Correction of the adjustable WO

1 = Correction of the channel-specific basic WO

2 = Correction of the basic reference

3 = Correction of the global basic WO

9 = Correction of the active WO or for G500, last active channel-specific basic WO

TEN THOUSANDS: Coarse or fine correction in the WO, basic WO or basic refer‐

ence

0 = Fine correction

6)

1 = Coarse correction

Work preparation

3.25 Programming cycles externally

NC programming

1158 Programming Manual, 12/2019, 6FC5398-2EP40-0BA0

Loading...

Loading...