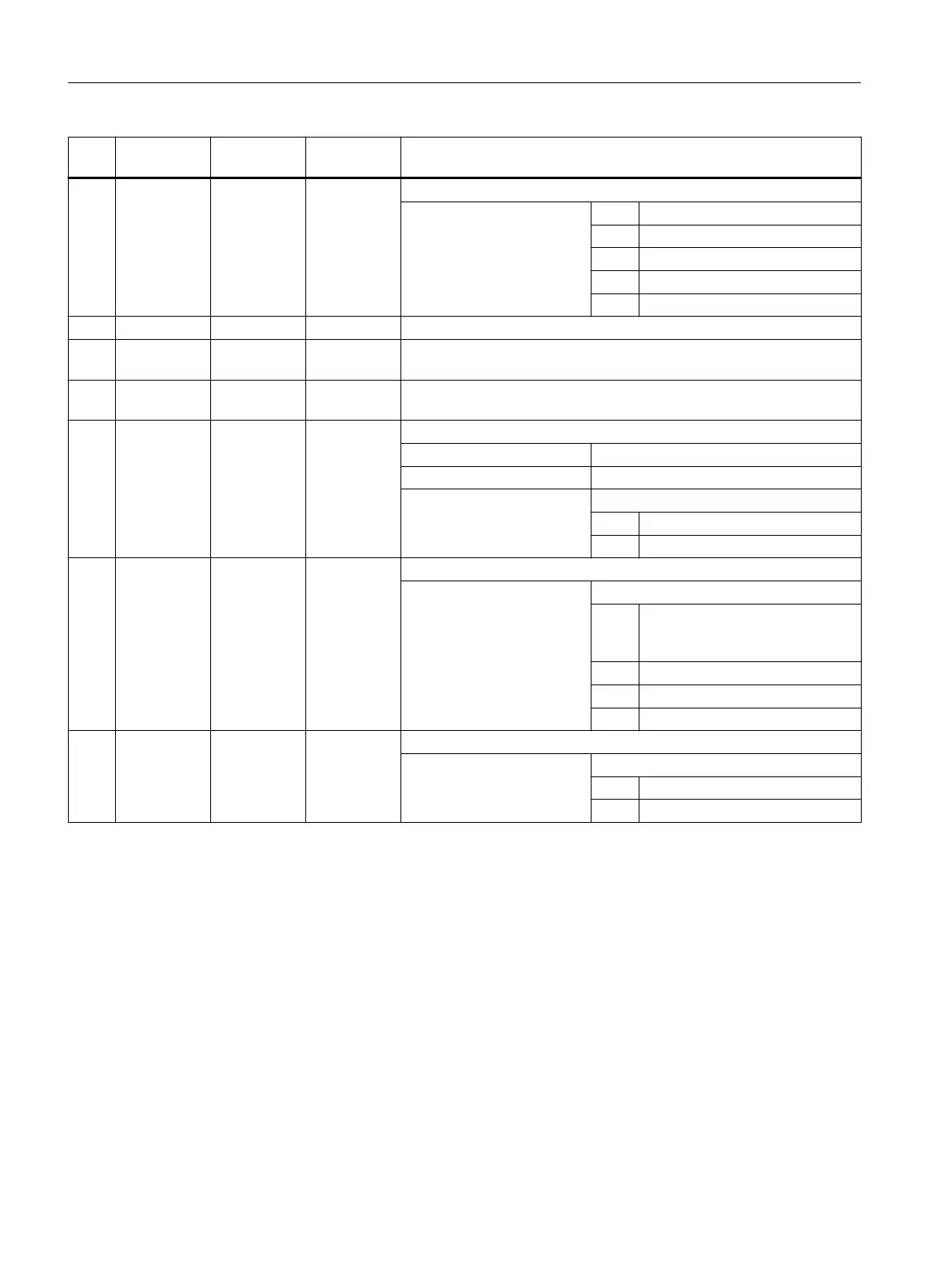

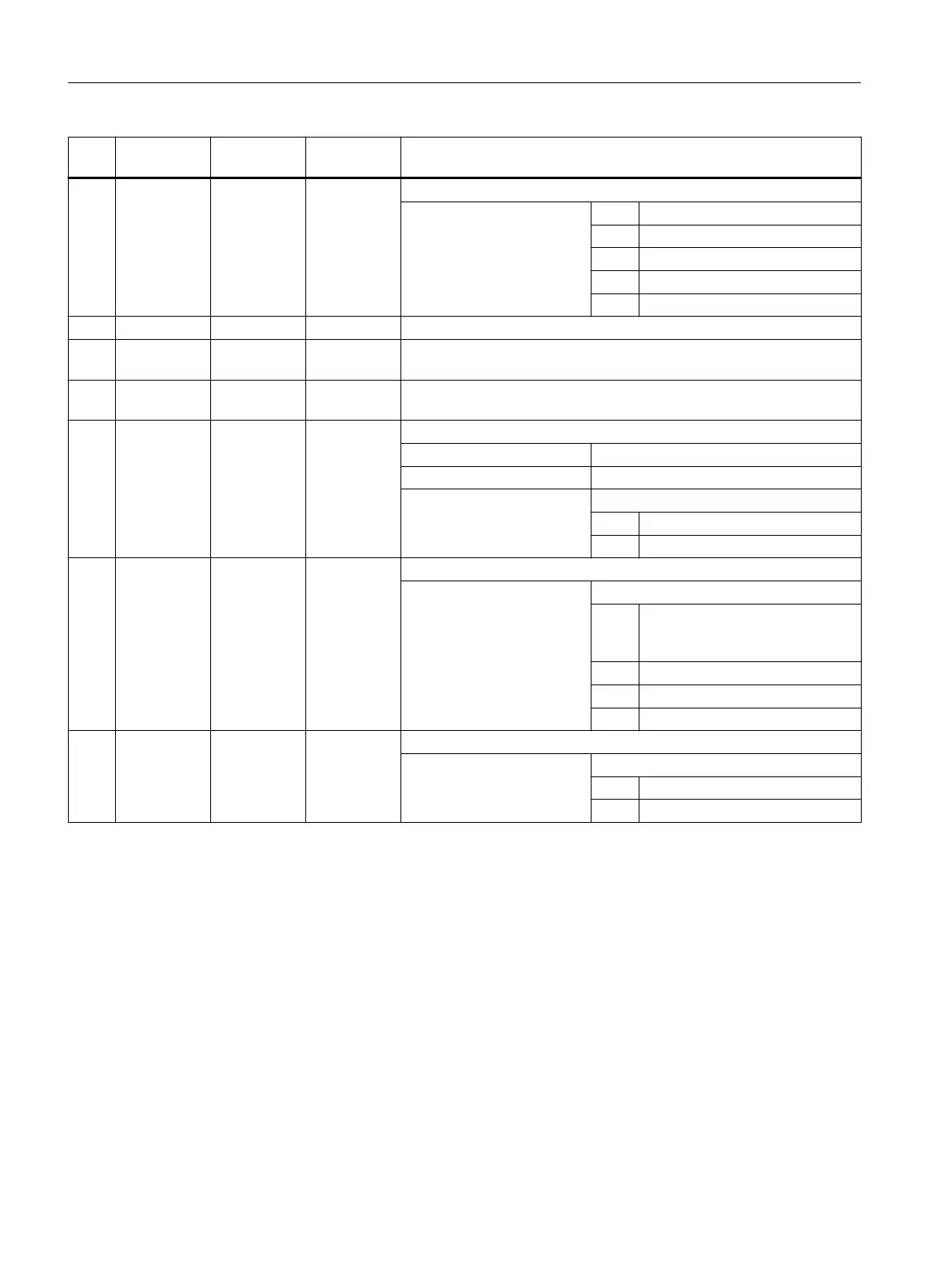

No. Parameter

mask

Parameter

internal

Data type Meaning

17 <_PITA> INT Evaluation of thread pitch

0 = Compatibility mode

1 = Pitch in mm

2 = Pitch in threads per inch (TPI)

3 = Pitch in inches

4 = Pitch as MODULE

18 <_PITM> STRING[15] String as marker for pitch input (for the interface only)

19 <_PTAB> STRING[20] String for thread table ("", "ISO", "BSW", "BSP", "UNC") (for the interface

only)

20 <_PTABA> STRING[20] String for selection from thread table (e.g. "M 10", "M 12", ...) (for the

interface only)

21 <_GMODE> INT Geometrical mode (evaluation of programmed geometrical data)

UNITS: Reserved

TENS: Reserved

HUNDREDS: Machining/calculation of start point

0 = Compatibility mode

1 = Normal machining

22 <_DMODE> INT Display mode

UNITS: Machining plane G17/G18/G19

0 = Compatibility, the plane effective

before the cycle call remains ac‐

tive

1 = G17 (only active in the cycle)

2 = G18 (only active in the cycle)

3 = G19 (only active in the cycle)

23 <_AMODE> INT Alternative mode

UNITS: Thread length (<_DP>)

0 = Absolute

1 = Incremental

3.25.1.16 CYCLE72 - Path milling

Syntax

CYCLE72(<_KNAME>, <_RTP>, <_RFP>, <_SDIS>, <_DP>, <_MID>, <_FAL>,

<_FALD>, <_FFP1>, <_FFD>, <_VARI>, <_RL>, <_AS1>, <_LP1>, <_FF3>,

<_AS2>, <_LP2>,<_UMODE>, <_FS>, <_ZFS>, <_GMODE>, <_DMODE>, <_AMODE>)

Work preparation

3.25 Programming cycles externally

NC programming

1052 Programming Manual, 12/2019, 6FC5398-2EP40-0BA0

Loading...

Loading...