3.25.3.14 CYCLE982 measuring cycle parameters

PROC CYCLE982(INT S_MVAR,INT S_KNUM,INT S_PRNUM,INT S_MA,INT S_MD,REAL S_ID,REAL S_FA,REAL

S_TSA,REAL S_VMS,REAL S_STA1,REAL S_CORA,REAL S_TZL,REAL S_TDIF,INT S_NMSP,INT S_EVNUM,INT

S_MCBIT,INT _DMODE,INT _AMODE)

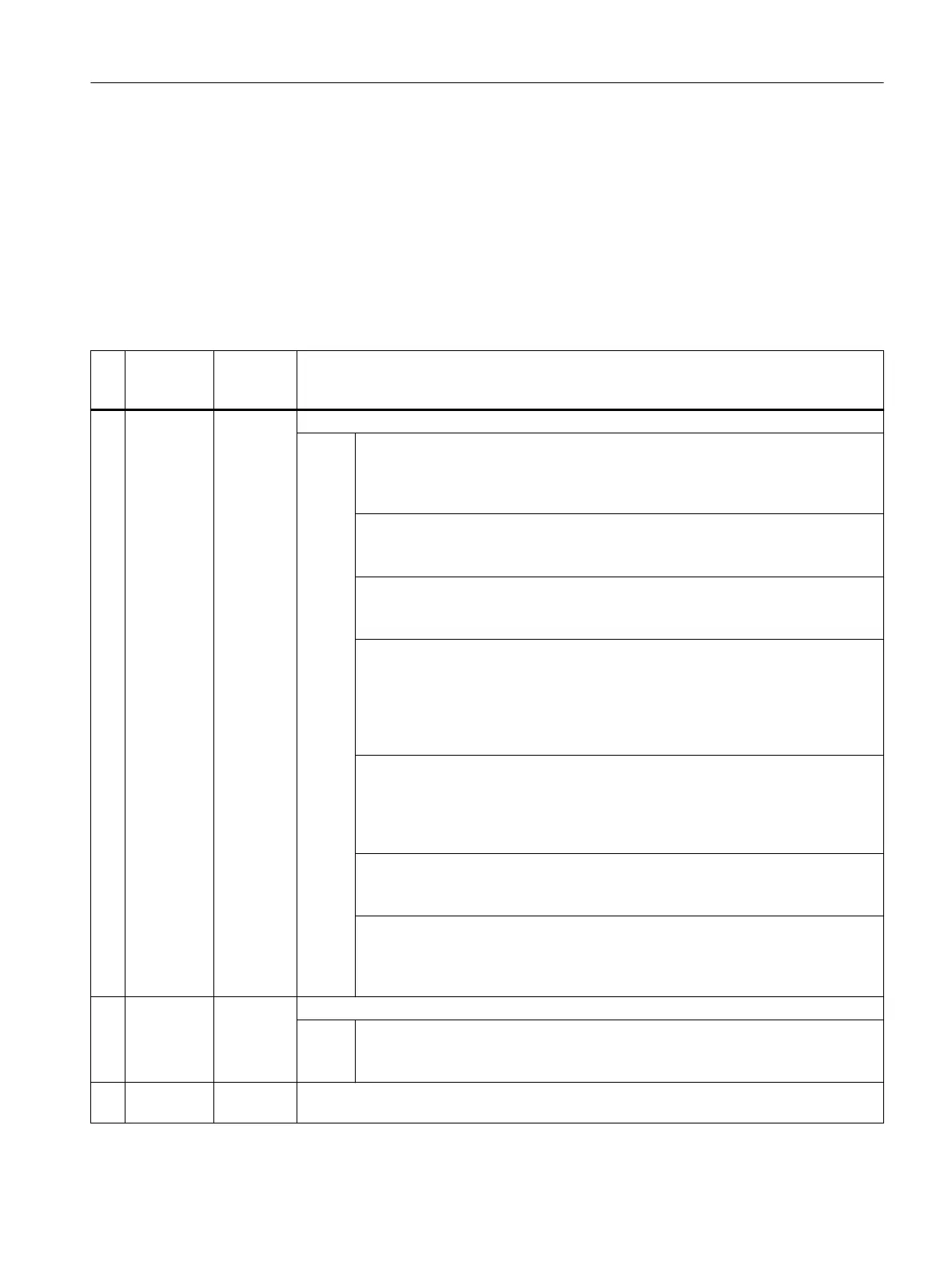

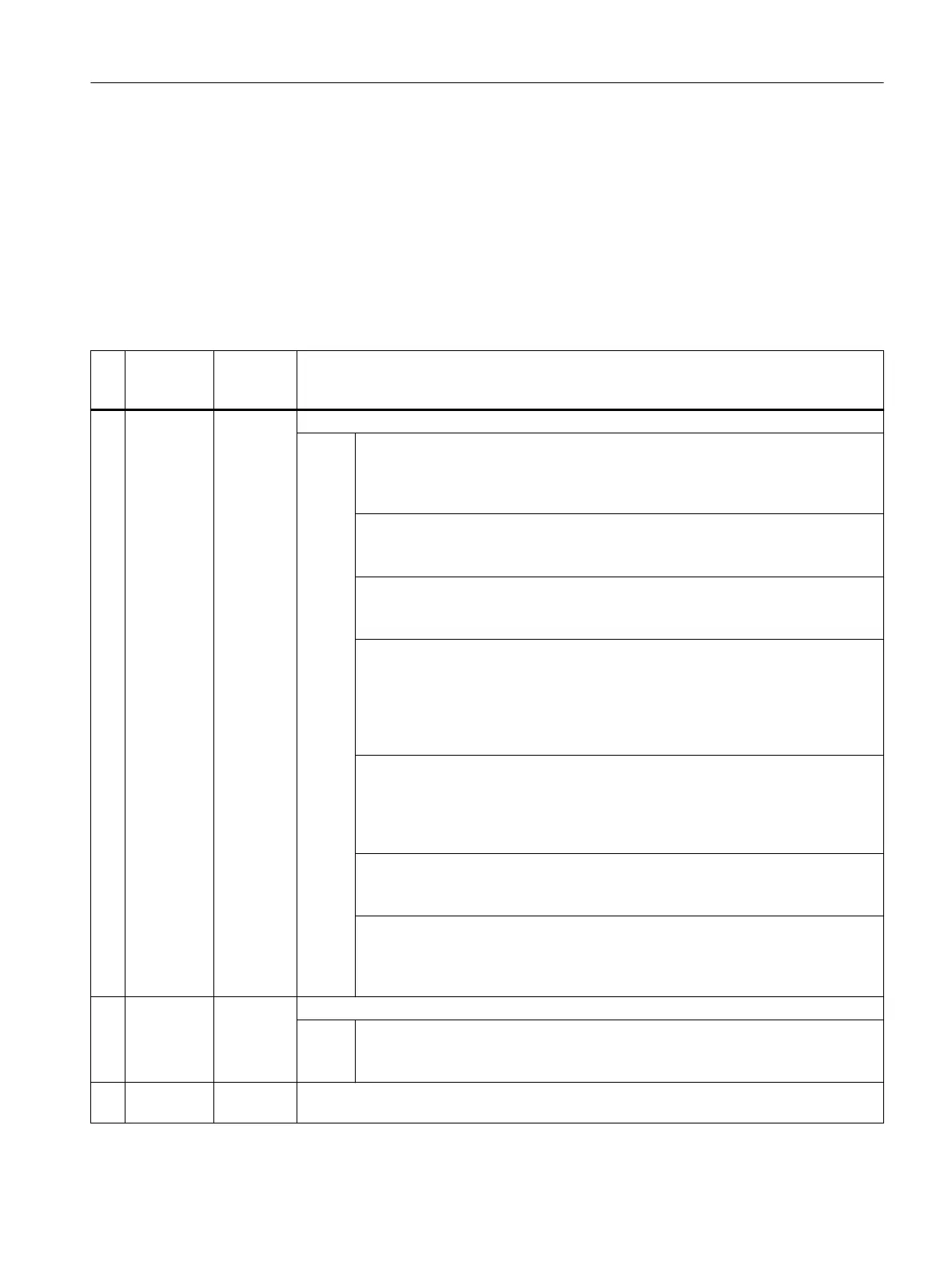

Table 3-21 CYCLE982 call parameters

1)

No. Screen

form param‐

eter

Cycle pa‐

rameter

Meaning

1 S_MVAR Measuring variant

Val‐

ues:

UNITS: Calibration/measurement

0 = Calibrate tool probe

1 = Single tool measurement

3)

2 = Multiple tool measurement, determine lengths and tool radius (for milling tools)

TENS: Calibration or measurement in the MCS or WCS

0 = Machine-related

4)

1 = Workpiece-related

HUNDREDS: Measurement with or without reversal for milling tools

0 = Measurement without reversal

1 = Measurement with reversal

THOUSANDS: Correction target for milling tools

0 = Determine length or length and radius (see S_MVAR 1st position)

1 = Determine radius if S_MVAR 1st position = 1

2 = Determine length and radius (face side) if S_MVAR 1st position = 1 or 2

3 = Determine side milling cutter upper cutting edge (rear side) and length and

radius

5)

TEN THOUSANDS: Position of the milling tool or the drill

0 = Axial position of the milling tool or drill, radius in 2nd axis of the plane (for G18

X)

7)

1 = Radial position of the milling tool or the drill, radius in 1st axis of the plane (for

G18 Z)

7)

HUNDRED THOUSANDS: Incremental calibration or measurement

0 = No specification

1 = Incremental calibration or measurement

ONE MILLION: Position spindle at starting angle S_STA1 (only for measurement of

milling tools)

0 = Spindle is not positioned

1 = Spindle is positioned at the starting angle S_STA1

2 Selection S_KNUM Offset variant

2)

Val‐

ues:

UNITS: Tool offset

0 = No specification (tool offset in geometry)

1 = Tool offset in wear

3 Icon+

number

S_PRNUM Number of the field of the probe parameters (not probe number)

(default=1)

Work preparation

3.25 Programming cycles externally

NC programming

Programming Manual, 12/2019, 6FC5398-2EP40-0BA0 1189

Loading...

Loading...