Program code Comment

N10 G17 S400 M3 ; Selection of the working plane, spindle clockwise

N20 G0 X40 Y-6 Z2 ; Approach the starting position

N30 G1 Z-3 F40 ; Tool infeed

N40 X12 Y-20 ; Travel on an inclined line

N50 G0 Z100 M30 ; Retraction for tool change

2.9.6 Circular interpolation

2.9.6.1 Overview

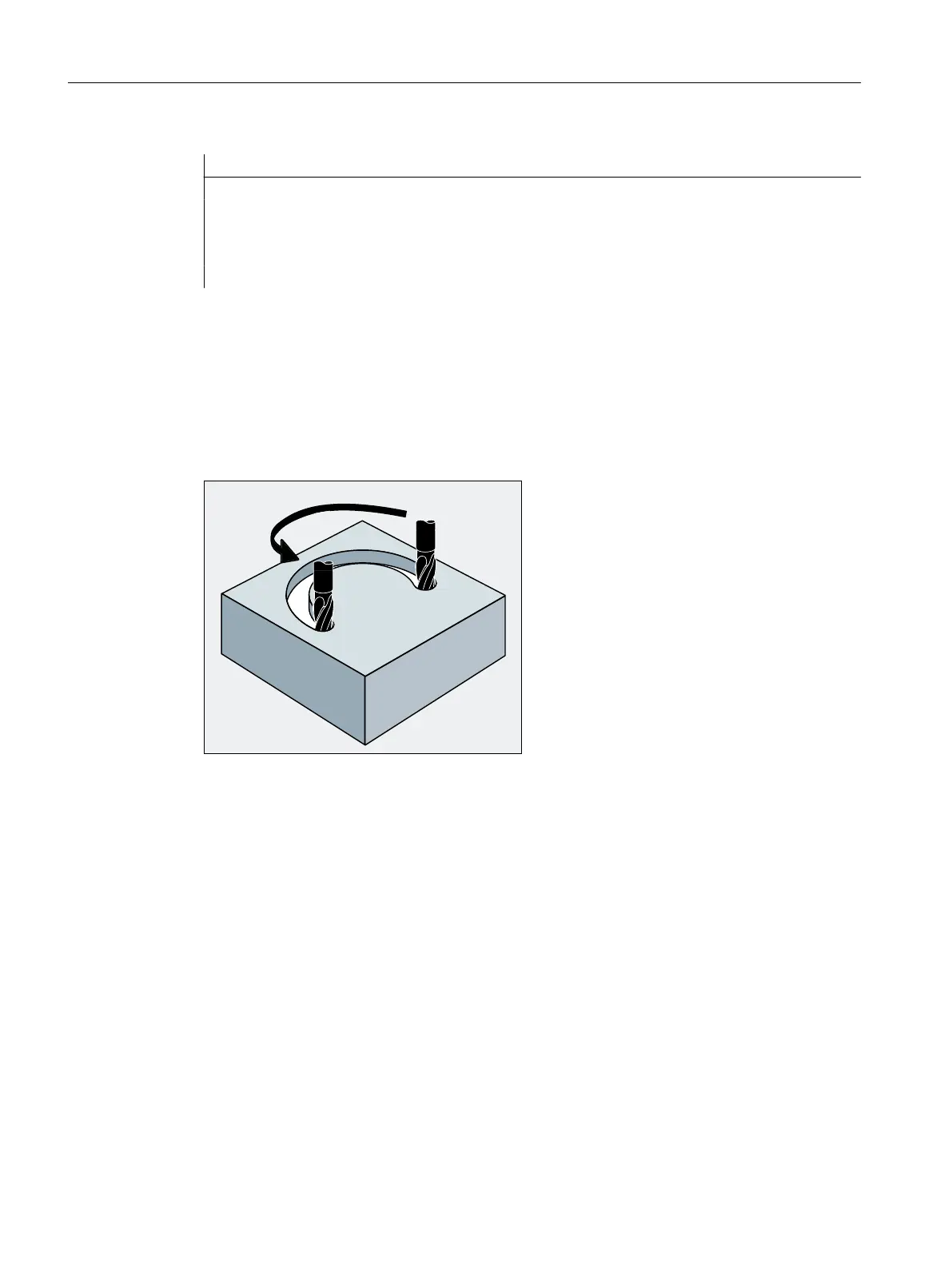

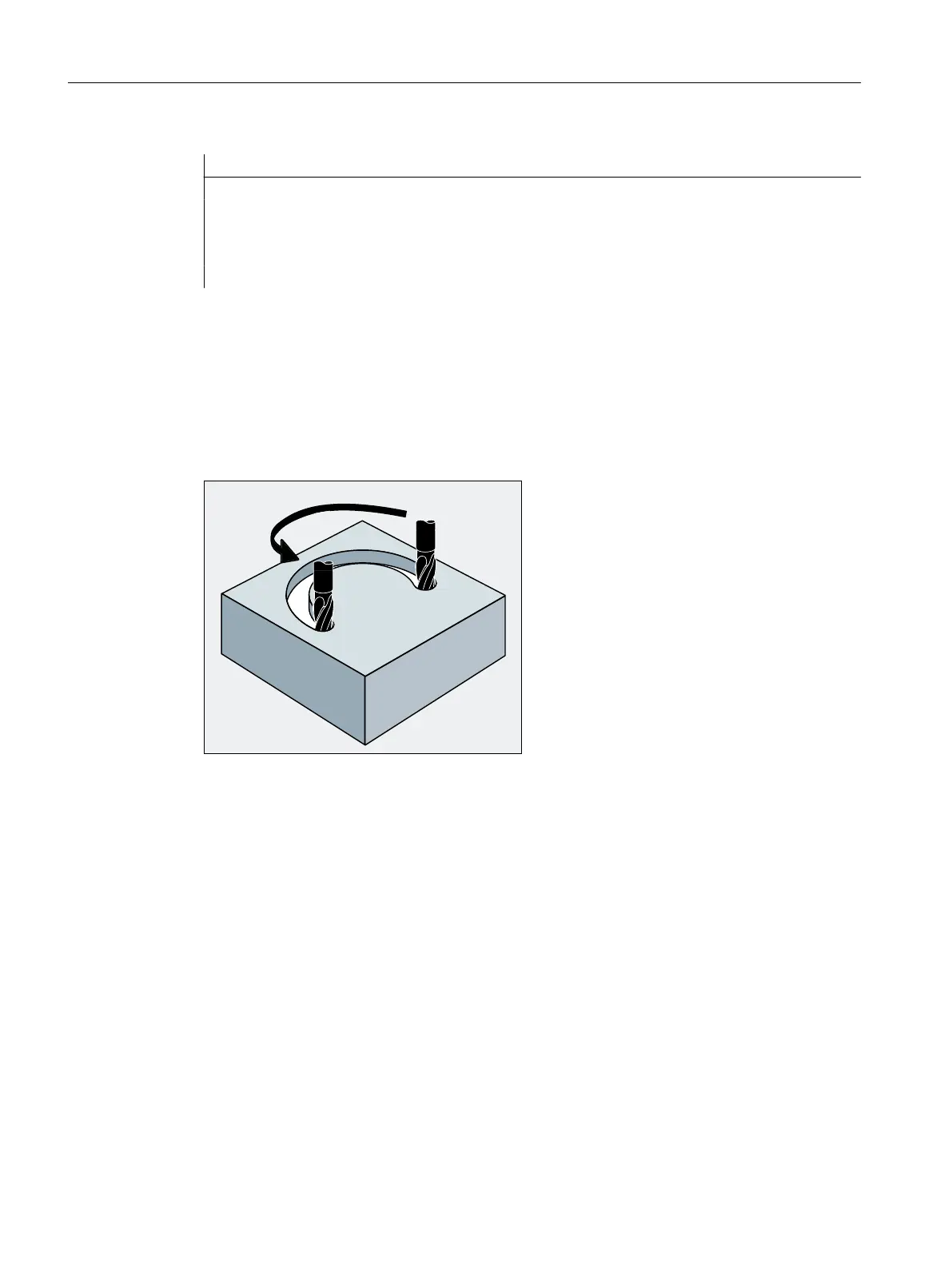

Circular interpolation enables the machining of full circles or arcs.

Figure 2-3 Application example: Milling a circular way

Programming options

The control system offers various options of programming circular movements. This allows the

user to implement almost any type of drawing dimension directly.

● Circular interpolation with center point and end point (G2/G3, X... Y... Z..., I... J... K...)

(Page 189)

● Circular interpolation with radius and end point (G2/G3, X... Y... Z..., CR) (Page 191)

● Circular interpolation with opening angle and end point / center point (G2/G3, X... Y... Z... /

I... J... K..., AR) (Page 193)

● Circular interpolation with polar coordinates (G2/G3, AP, RP) (Page 195)

● Circular interpolation with intermediate point and end point (CIP, X... Y... Z..., I1... J1... K1...)

(Page 197)

● Circular interpolation with tangential transition (CT, X... Y... Z...) (Page 200)

Fundamentals

2.9 Motion commands

NC programming

188 Programming Manual, 12/2019, 6FC5398-2EP40-0BA0

Loading...

Loading...