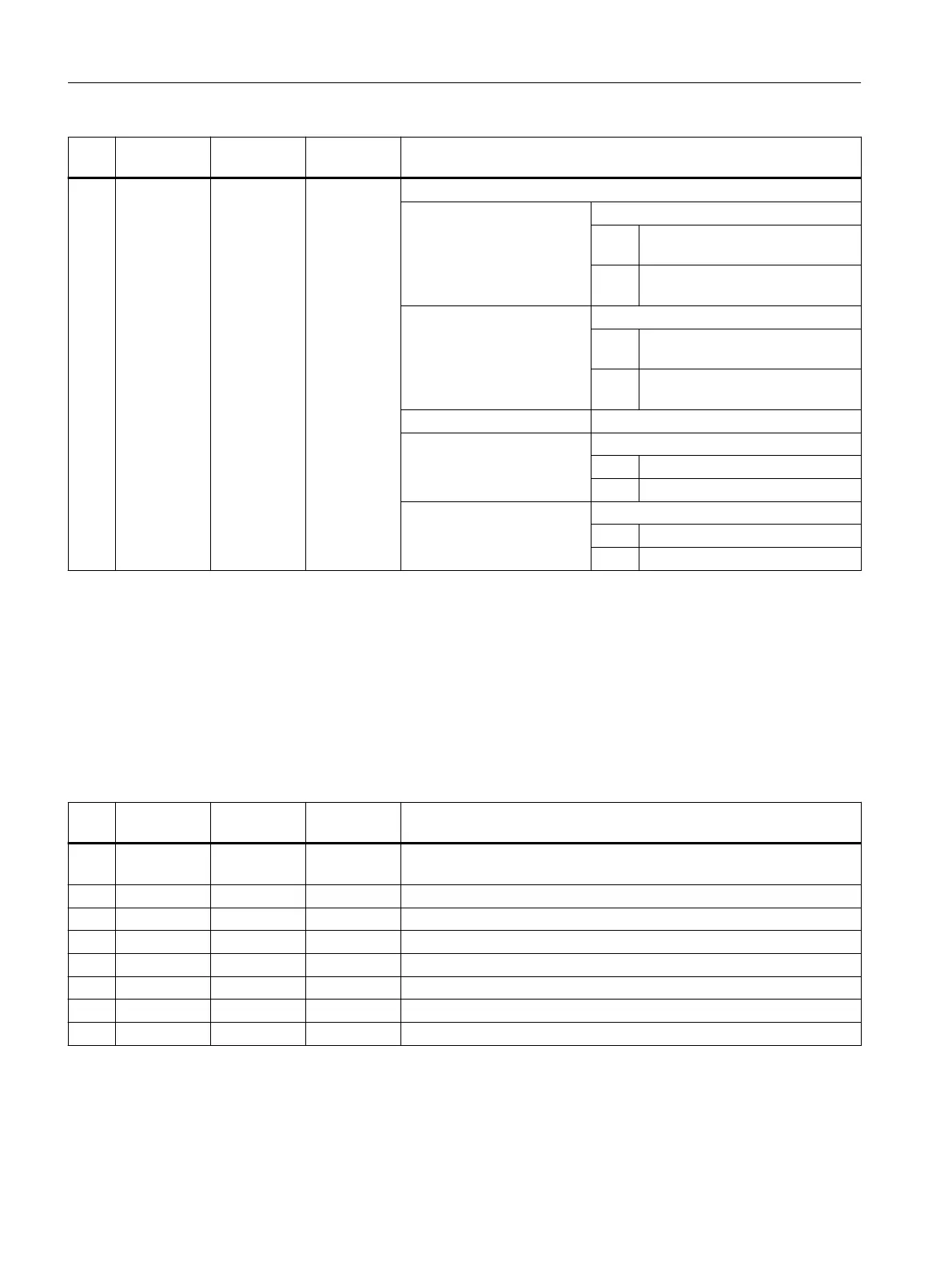

No. Parameter

mask

Parameter

internal

Data type Meaning

21 <_AMODE> INT Alternative mode

UNITS: Depth for speed reduction (<_DIAG1>)

0 = Absolute, value of transverse ax‐

is in the diameter

1 = Incremental, value of transverse

axis in the radius

TENS: Final depth (<_DIAG2>)

0 = Absolute, value of transverse ax‐

is in the diameter

1 = Incremental, value of transverse

axis in the radius

HUNDREDS: Reserved

THOUSANDS: Radius/chamfer (<_RC>)

0 = Radius

1 = Chamfer

TEN THOUSANDS: Spindle speed / cutting rate (<_SV1>)

0 = Constant spindle speed

1 = Constant cutting rate

3.25.1.28 CYCLE95 - contour cutting

Syntax

CYCLE95(<NPP>, <MID>, <FALZ>, <FALX>, <FAL>, <FF1>, <FF2>, <FF3>,

<_VARI>, <DT>, <DAM>, <_VRT>, <_GMODE>, <_DMODE>)

Parameters

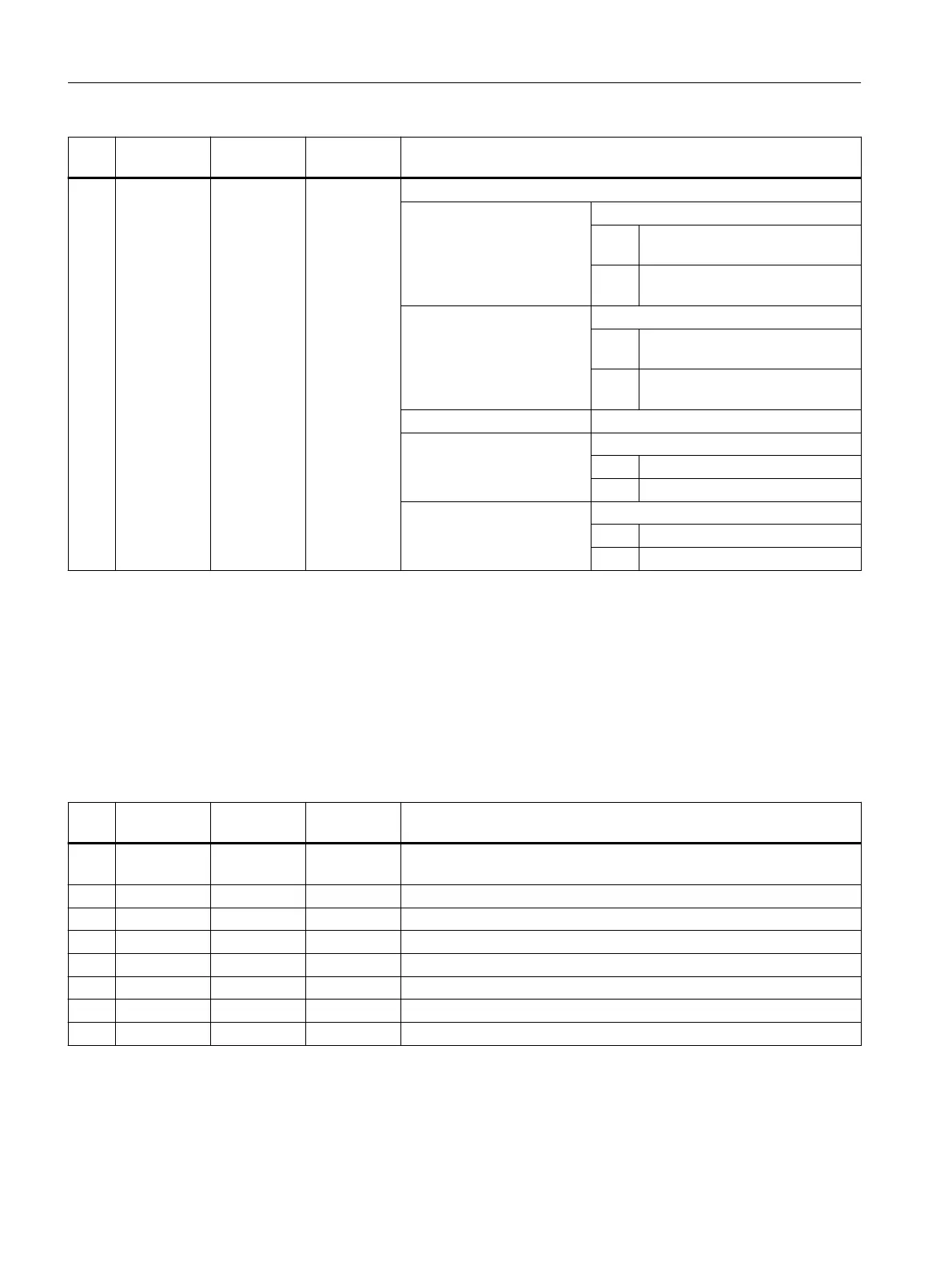

No. Parameter

mask

Parameter

internal

Data type Meaning

1 CON <NPP> STRING

[140]

Contour name

2 D <MID> REAL Maximum depth infeed during roughing, see <_GMODE>

3 UZ <FALZ> REAL Finishing allowance in Z

4 UX <FALX> REAL Finishing allowance in X

5 U <FAL> REAL Finishing allowance parallel to contour (effective in both axes)

6 F <FF1> REAL Feedrate for roughing

7 FY <FF2> REAL Insertion feedrate, relief cuts

8 FS <FF3> REAL Finishing feedrate

Work preparation

3.25 Programming cycles externally

NC programming

1078 Programming Manual, 12/2019, 6FC5398-2EP40-0BA0

Loading...

Loading...