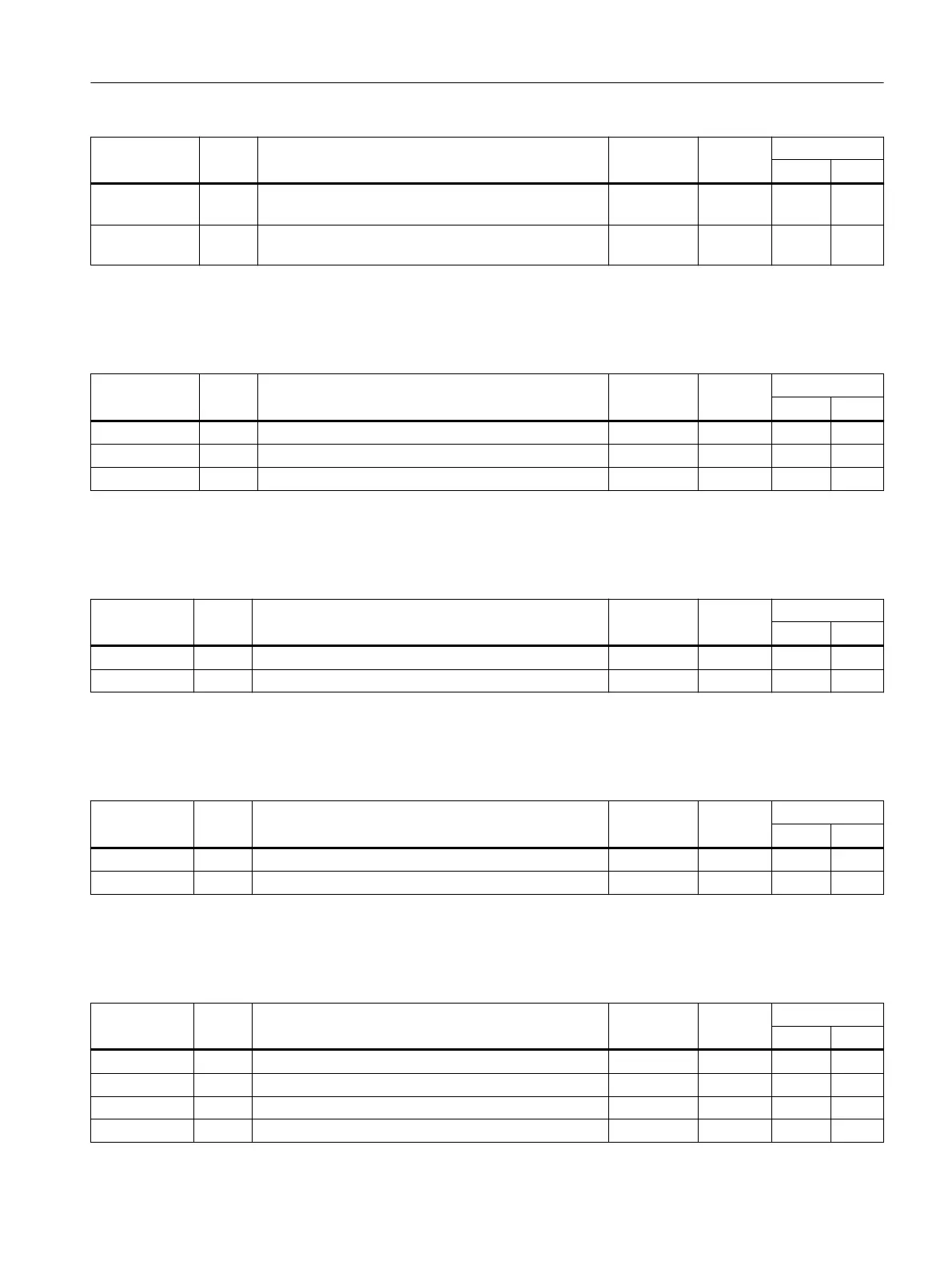

G command No.

1)

Meaning MD20150

2)

W

3)

STD

4)

SAG MH

CUT3DCD 11 3D TRC in relation to a differential tool for circumfer‐

ential milling

+ m

CUT3DFD 12 3D TRC in relation to a differential tool for face milling

with change in orientation

+ m

4.3.23 G group 23: Collision monitoring at inside contours

G command No.

1)

Meaning MD20150

2)

W

3)

STD

4)

SAG MH

CDOF 1 Collision detection OFF + m x

CDON 2 Collision detection ON + m

CDOF2 3 Collision detection OFF for 3D circumferential milling + m

4.3.24 G group 24: Precontrol

G command No.

1)

Meaning MD20150

2)

W

3)

STD

4)

SAG MH

FFWOF 1 Feedforward control OFF + m x

FFWON 2 Feedforward control ON + m

4.3.25 G group 25: Tool orientation reference

G command No.

1)

Meaning MD20150

2)

W

3)

STD

4)

SAG MH

ORIWKS 1 Tool orientation in workpiece coordinate system (WCS) + m x

ORIMKS 2 Tool orientation in machine coordinate system (MCS) + m

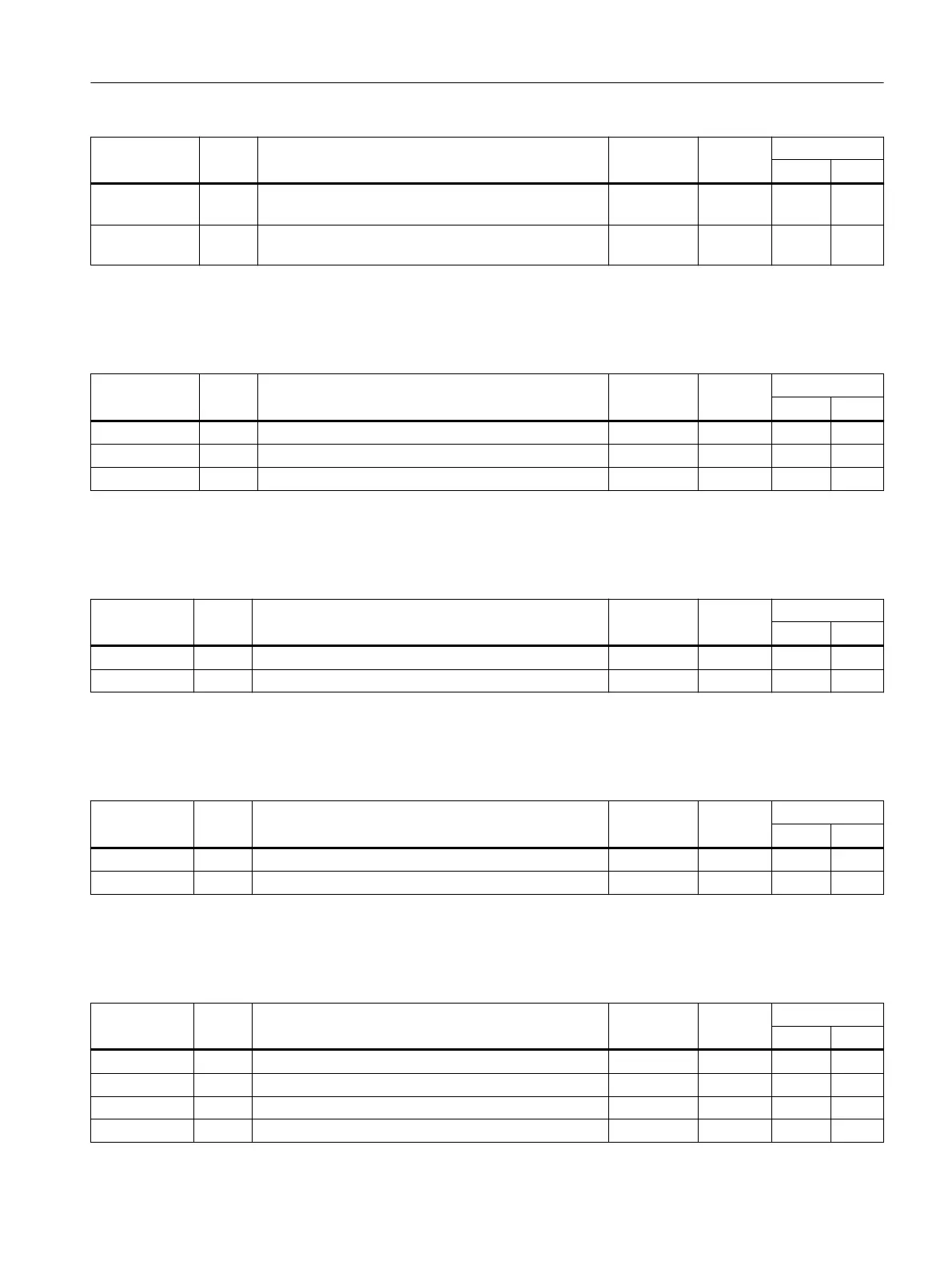

4.3.26 G group 26: Repositioning mode for REPOS (modal)

G command No.

1)

Meaning MD20150

2)

W

3)

STD

4)

SAG MH

RMB 1 Repositioning to start of block - m

RMI 2 Repositioning to interrupt point - m x

RME 3 Repositioning to end of block - m

RMN 4 Repositioning to the nearest path point - m

Tables

4.3 G commands

NC programming

Programming Manual, 12/2019, 6FC5398-2EP40-0BA0 1255

Loading...

Loading...