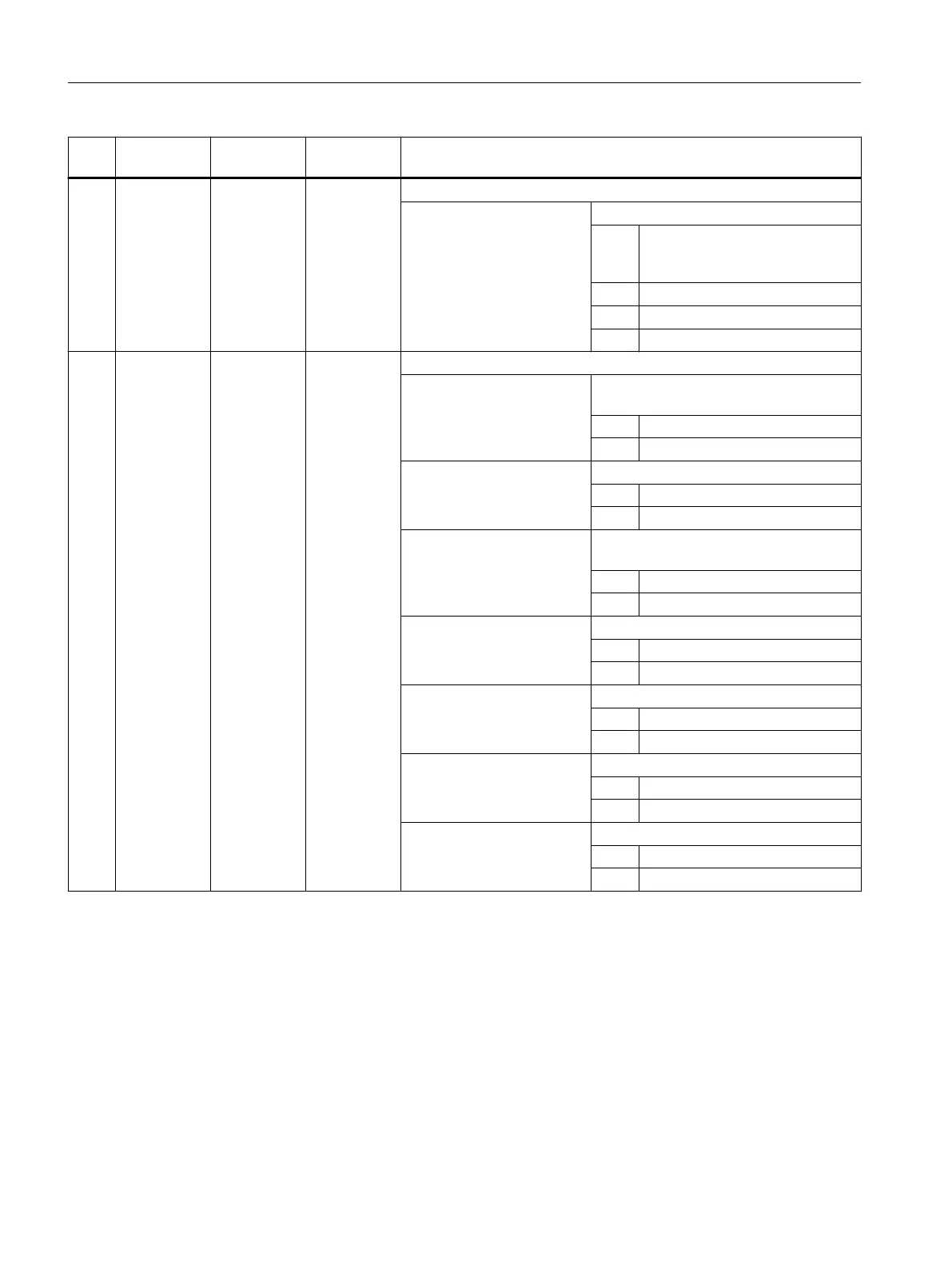

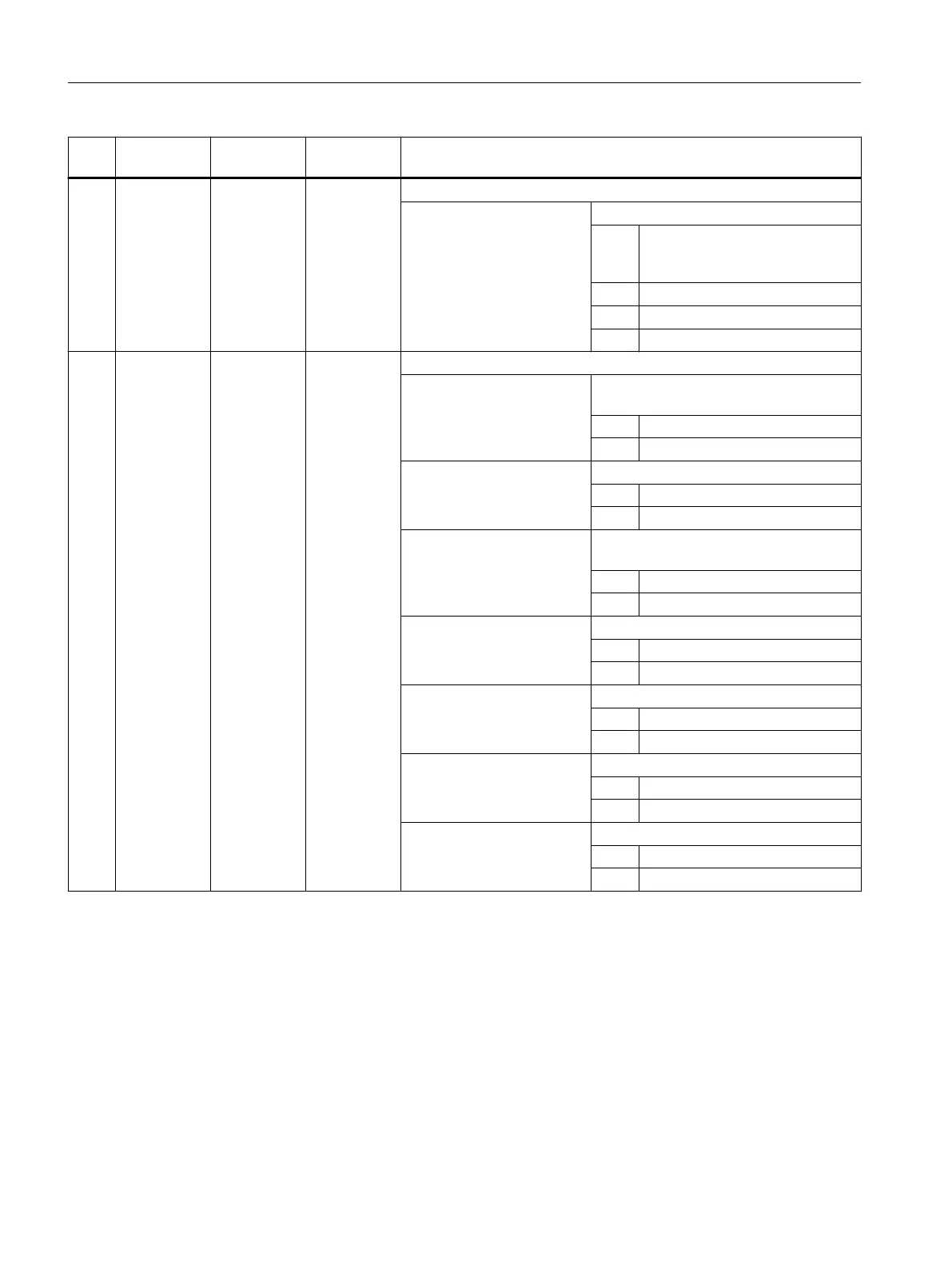

No. Parameter

mask

Parameter

internal

Data type Meaning

25 <_DMODE> INT Display mode

UNITS: Machining plane G17/G18/G19

0 = Compatibility, the plane effective

before the cycle call remains ac‐

tive

1 = G17 (only active in the cycle)

2 = G18 (only active in the cycle)

3 = G19 (only active in the cycle)

26 <_AMODE> INT Alternative mode

UNITS: Dimensioning for top of groove (for inter‐

face only)

0 = At the reference point

1 = Opposite the reference point

TENS: Depth

0 = Absolute

1 = Incremental

HUNDREDS: Dimensioning for width (for interface on‐

ly)

0 = At outer diameter (top)

1 = At inner diameter (bottom)

THOUSANDS: Radius/chamfer 1 (<_RCO1>)

0 = Radius

1 = Chamfer

TEN THOUSANDS: Radius/chamfer 2 (<_RCI1>)

0 = Radius

1 = Chamfer

HUNDRED THOUSANDS: Radius/chamfer 3 (<_RCI2>)

0 = Radius

1 = Chamfer

ONE MILLION: Radius/chamfer 4 (<_RCO2>)

0 = Radius

1 = Chamfer

3.25.1.42 CYCLE940 – undercut form E and F / undercut thread

Various undercuts can be programmed using the CYCLE940 cycle. In some cases, these differ

significantly regarding the parameterization.

The additional columns in the table indicate which parameters are required for which undercut

type. They correspond to the vertical selection softkeys in the cycle screen form:

● E: Undercut form E

● F: Undercut form F

Work preparation

3.25 Programming cycles externally

NC programming

1118 Programming Manual, 12/2019, 6FC5398-2EP40-0BA0

Loading...

Loading...