5-76

CONNECTING RODS AND PISTONS

ENG

CAUTION:

NOTE:

NOTE:

CHECKING THE BIG END BEARINGS

(for CAL)

1. Measure:

S crankshaft-pin-to-big-end-bearing clear-

ance

Out of specification ! Replace the big end

bearings.

Crankshaft-pin-to-big-end-bearing

clearance

0.028 X 0.052 mm

(0.0011 X 0.0020 in)

The following procedure applies to all of the

connecting rods.

Do not interchange the big end bearings and

connecting rods. To obtain the correct

crankshaft-pin-to-big-end-bearing clear-

ance and prevent engine damage, the big

end bearings must be installed in their origi-

nal positions.

a. Clean the big end bearings, crankshaft pins,

and the inside of the connecting rod halves.

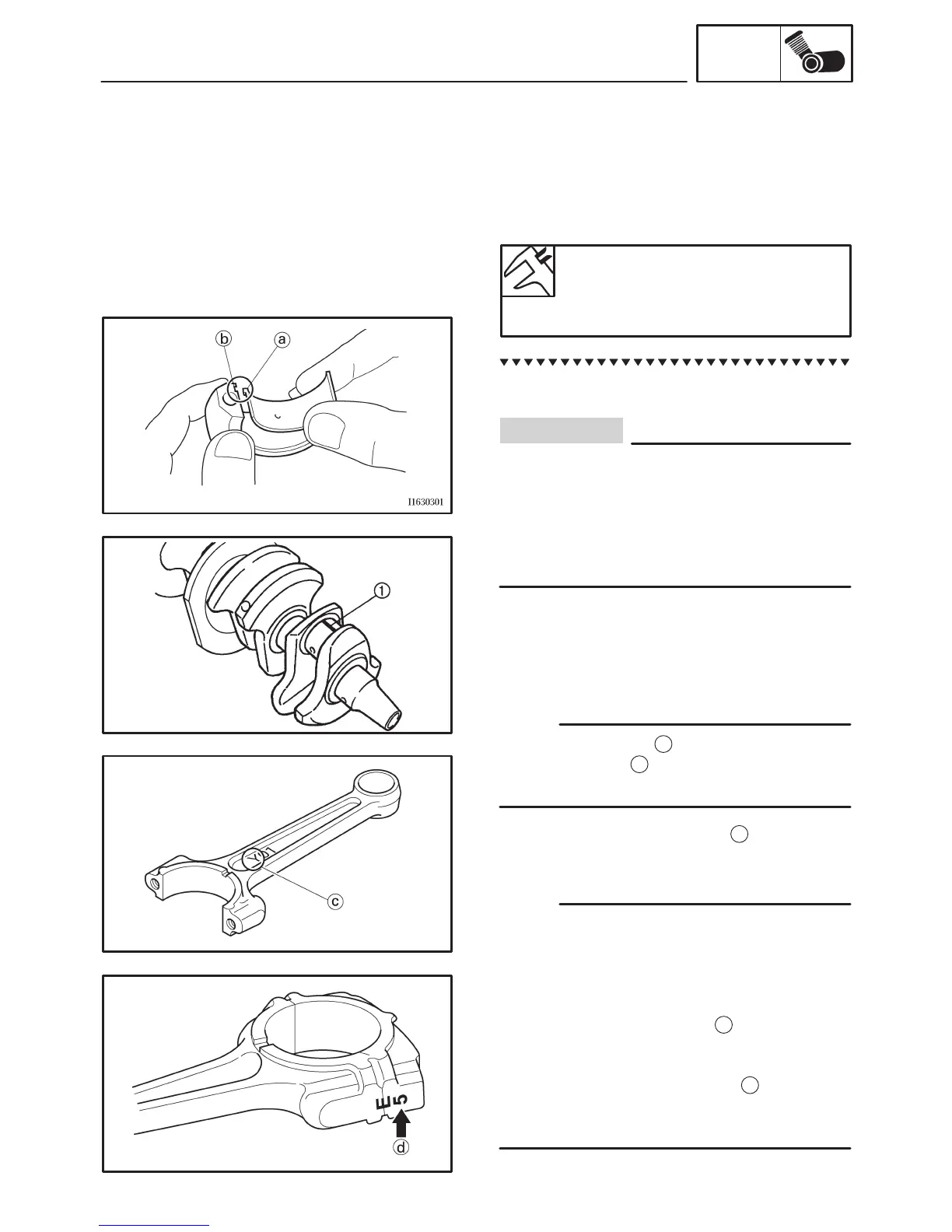

b. Install the big end upper bearing into the con-

necting rod and the big end lower bearing

into the connecting rod cap.

Align the projections

a

on the big end bearings

with the notches

b

in the connecting rod and

connecting rod cap.

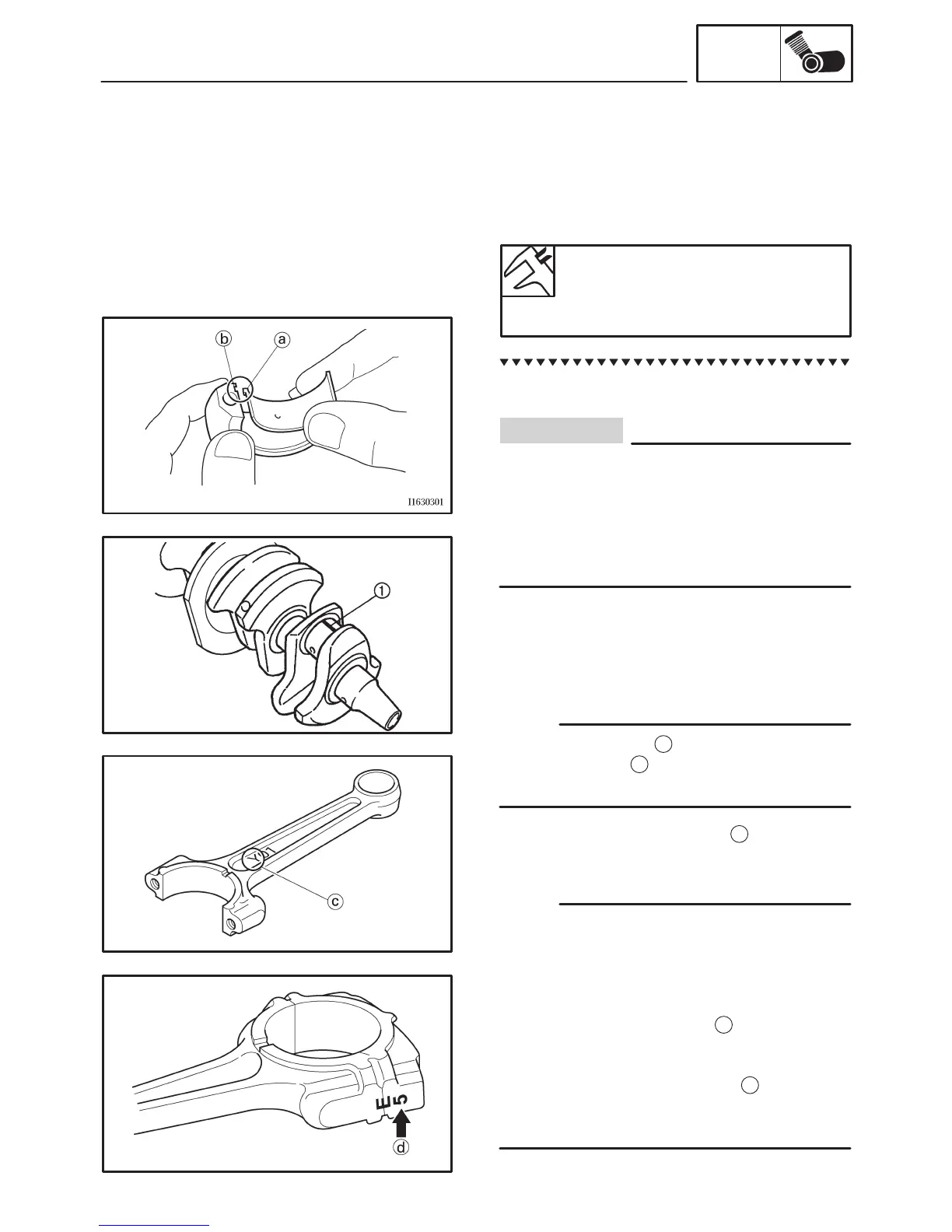

c. Put a piece of Plastigauge

1

on the crank-

shaft pin.

d. Assemble the connecting rod halves.

S Do not move the connecting rod or crankshaft

until the clearance measurement has been

completed.

S Lubricate the bolt threads and seats with mo-

lybdenum disulfide grease.

S Make sure that the “Y” mark

c

on the connect-

ing rod faces towards the left side of the crank-

shaft.

S Make sure that the characters

d

on both the

connecting rod and connecting rod cap are

aligned.

Loading...

Loading...