3-20

PERIODIC MAINTENANCE

EAS30641

CHECKING THE WHEEL BEARINGS

The following procedure applies to all of the

wheel bearings.

1. Check:

• Wheel bearings

Refer to “FRONT WHEEL” on page 4-22 and

“REAR WHEEL” on page 4-30.

EAS30802

CHECKING THE SWINGARM OPERATION

1. Check:

• Swingarm operation

Swingarm not working properly Check the

swingarm.

Refer to “REMOVING THE SWINGARM” on

page 4-102.

2. Check:

• Swingarm excessive play

Refer to “REMOVING THE SWINGARM” on

page 4-102.

EAS31431

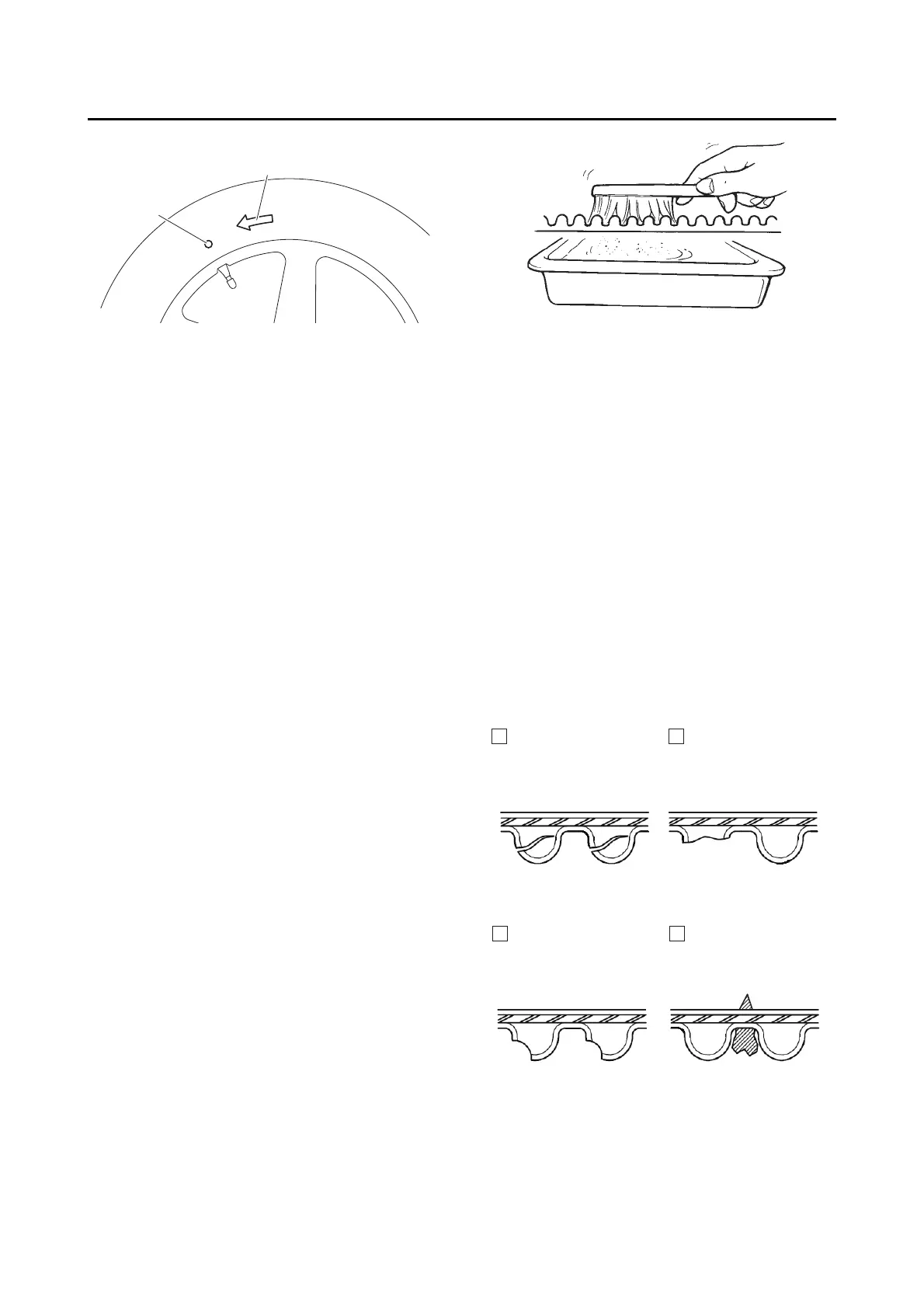

CHECKING THE DRIVE BELT

1. Remove:

• Drive belt upper guard and lower guard

Refer to “REAR WHEEL” on page 4-30 and

“BELT DRIVE” on page 4-94.

2. Clean:

• Drive belt

a. Wipe the drive belt with a clean cloth.

b. Put the drive belt in a mixture of mild deter-

gent and water. Then, remove any dirt from

the drive belt.

c. Remove the drive belt from the mixture and

rinse it off with clean water. Then, let the

drive belt thoroughly dry.

3. Check:

• Drive belt

Exposed cogs or external cracks “A”

Replace.

Missing teeth “B” Replace.

Hook wear “C” Replace.

Stone damage “D”, “E” Replace.

Internal tooth cracks (hairline) “F” OK to

run, but monitor condition.

Chipping (not serious) “G” OK to run, but

monitor condition.

Fuzzy edge cord “H” OK to run, but moni-

tor condition.

Edge wear of cogs (or belt) “I” OK to run,

but monitor condition.

Refer to “CHECKING THE DRIVE BELT” on

page 4-95.

Tooth cloth wear “J” Replace.

Side cracks (hairline) “K” Replace.

A

B

C

D

Loading...

Loading...