5-26

VALVES AND VALVE SPRINGS

3. Eliminate:

• Carbon deposit

(from the valve face and valve seat)

4. Check:

• Valve face

Pitting/wear Grind the valve face.

• Valve stem end

Mushroom shape or diameter larger than the

body of the valve stem Replace the valve.

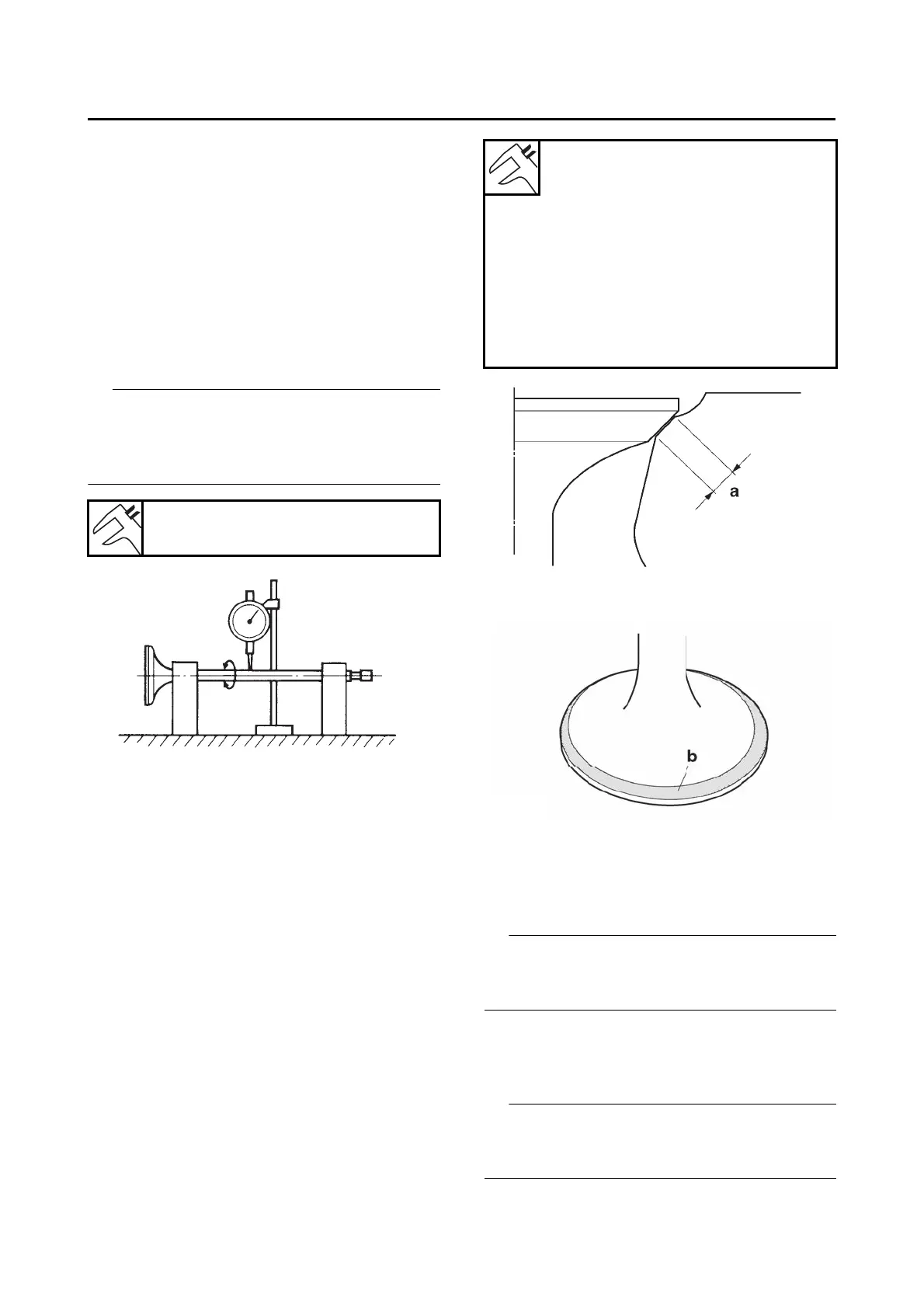

5. Measure:

• Valve stem runout

Out of specification Replace the valve.

• When installing a new valve, always replace

the valve guide.

• If the valve is removed or replaced, always re-

place the valve stem seal.

EAS30285

CHECKING THE VALVE SEATS

The following procedure applies to all of the

valves and valve seats.

1. Eliminate:

• Carbon deposit

(from the valve face and valve seat)

2. Check:

• Valve seat

Pitting/wear Replace the cylinder head.

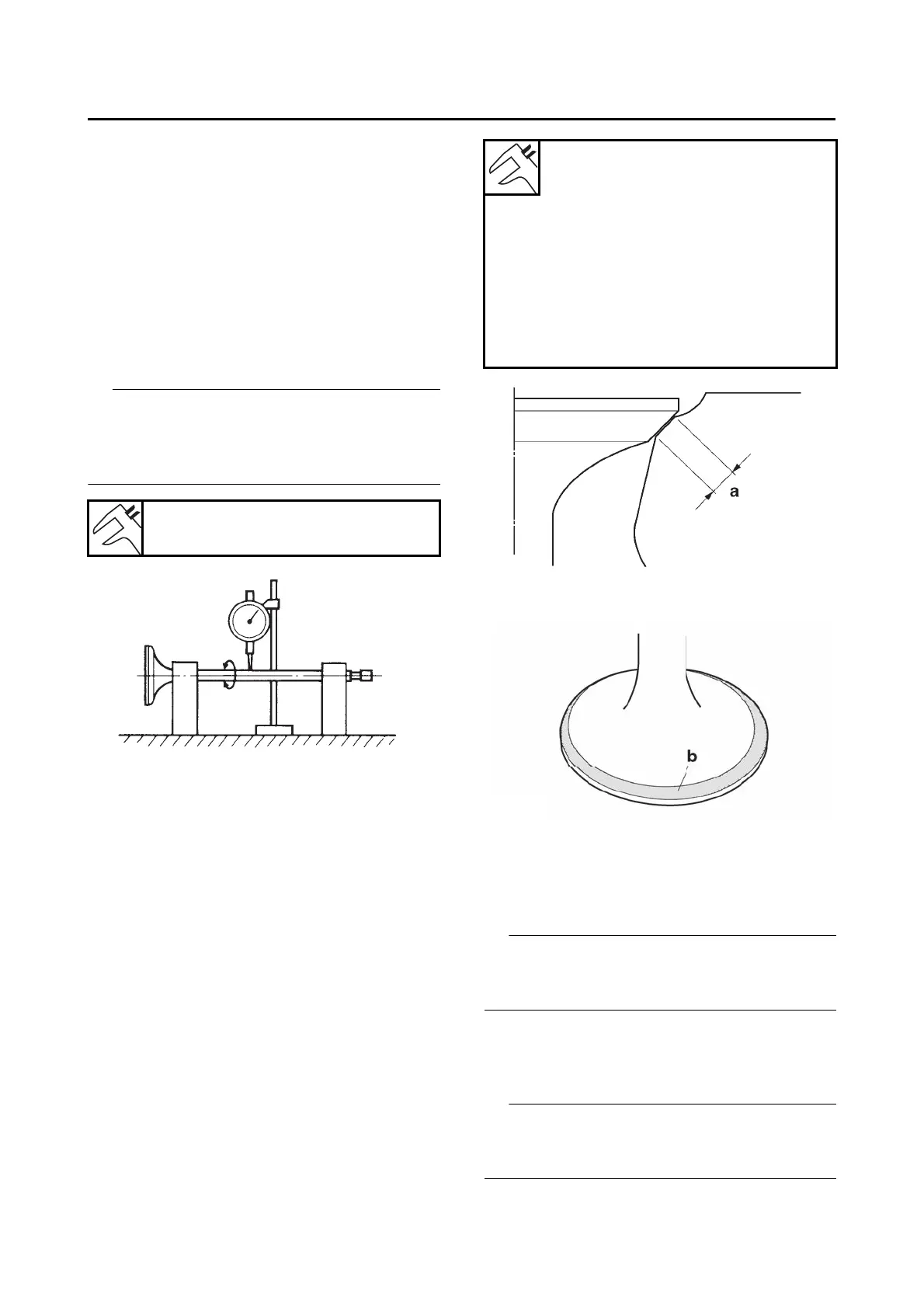

3. Measure:

• Valve seat width “a”

Out of specification Replace the cylinder

head.

a. Apply blue layout fluid “b” onto the valve

face.

b. Install the valve into the cylinder head.

c. Press the valve through the valve guide and

onto the valve seat to make a clear impres-

sion.

d. Measure the valve seat width.

Where the valve seat and valve face contacted

one another, the blue layout fluid will have been

removed.

4. Lap:

• Valve face

• Valve seat

After replacing the cylinder head or replacing the

valve and valve guide, the valve seat and valve

face should be lapped.

Valve stem runout

0.010 mm (0.0004 in)

Valve seat contact width (intake)

0.90–1.10 mm (0.0354–0.0433

in)

Limit

1.6 mm (0.06 in)

Valve seat contact width (ex-

haust)

0.90–1.10 mm (0.0354–0.0433

in)

Limit

1.6 mm (0.06 in)

Loading...

Loading...