5-31

CYLINDER AND PISTONS

EAS30289

REMOVING THE PISTON

The following procedure applies to all of the pis-

ton.

1. Remove:

• Piston pin clip

• Piston pin “1”

• Piston “2”

ECA13810

Do not use a hammer to drive the piston pin

out.

• Before removing the piston pin clip, cover the

crankcase opening with a clean rag to prevent

the piston pin clip from falling into the crank-

case.

• For reference during installation, put an identi-

fication mark on each piston crown.

• Before removing the piston pin, deburr the pis-

ton pin clip’s groove and the piston’s pin bore

area. If both areas are deburred and the piston

pin is still difficult to remove, remove it with the

piston pin puller set “3”.

2. Remove:

• Top ring

• 2nd ring

•Oil ring

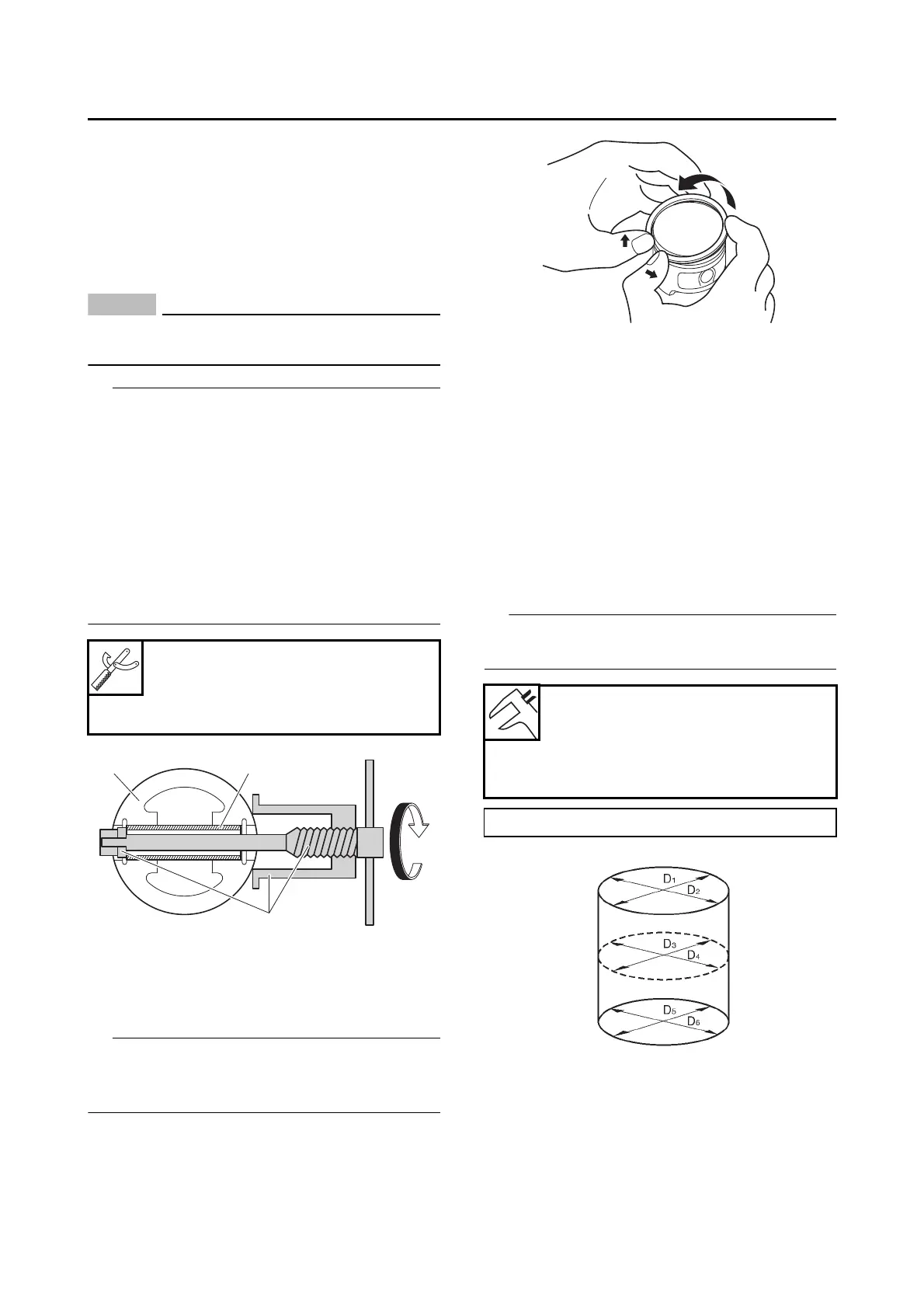

When removing a piston ring, open the end gap

with your fingers and lift the other side of the ring

over the piston crown.

EAS30291

CHECKING THE CYLINDERS AND PISTONS

The following procedure applies to all of the cyl-

inders and pistons.

1. Check:

• Piston wall

• Cylinder wall

Vertical scratches Replace the cylinder,

piston and piston rings as a set.

2. Measure:

• Piston-to-cylinder clearance

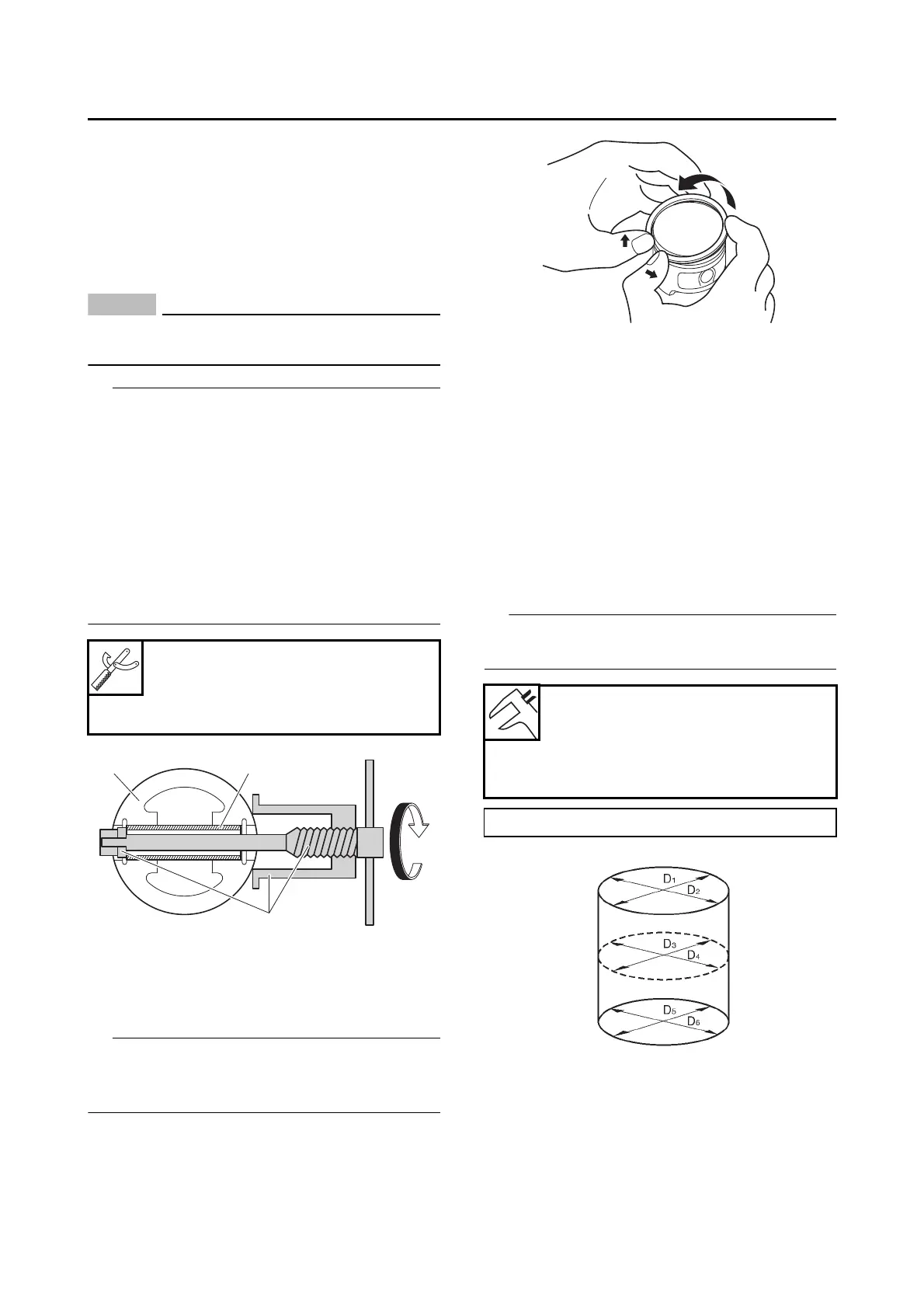

a. Measure cylinder bore with the cylinder

bore gauge.

Measure cylinder bore by taking side-to-side

and front-to-back measurements of the cylinder.

b. If out of specification, replace the cylinder,

piston and piston rings as a set.

c. Measure piston diameter “b” with the mi-

crometer.

Piston pin puller set

90890-01304

Piston pin puller

YU-01304

Bore

70.000–70.010 mm

(2.7559–2.7563 in)

Wear limit

70.060 mm (2.7583 in)

Bore = maximum of D

1

, D

2

, D

3

, D

4

, D

5

, D

6

Loading...

Loading...