5-32

CYLINDER AND PISTONS

d. If out of specification, replace the piston and

piston rings as a set.

e. Calculate the piston-to-cylinder clearance

with the following formula.

f. If out of specification, replace the cylinder,

piston and piston rings as a set.

EAS30292

CHECKING THE PISTON RINGS

1. Measure:

• Piston ring side clearance

Out of specification Replace the piston

and piston rings as a set.

Before measuring the piston ring side clearance,

eliminate any carbon deposits from the piston

ring grooves and piston rings.

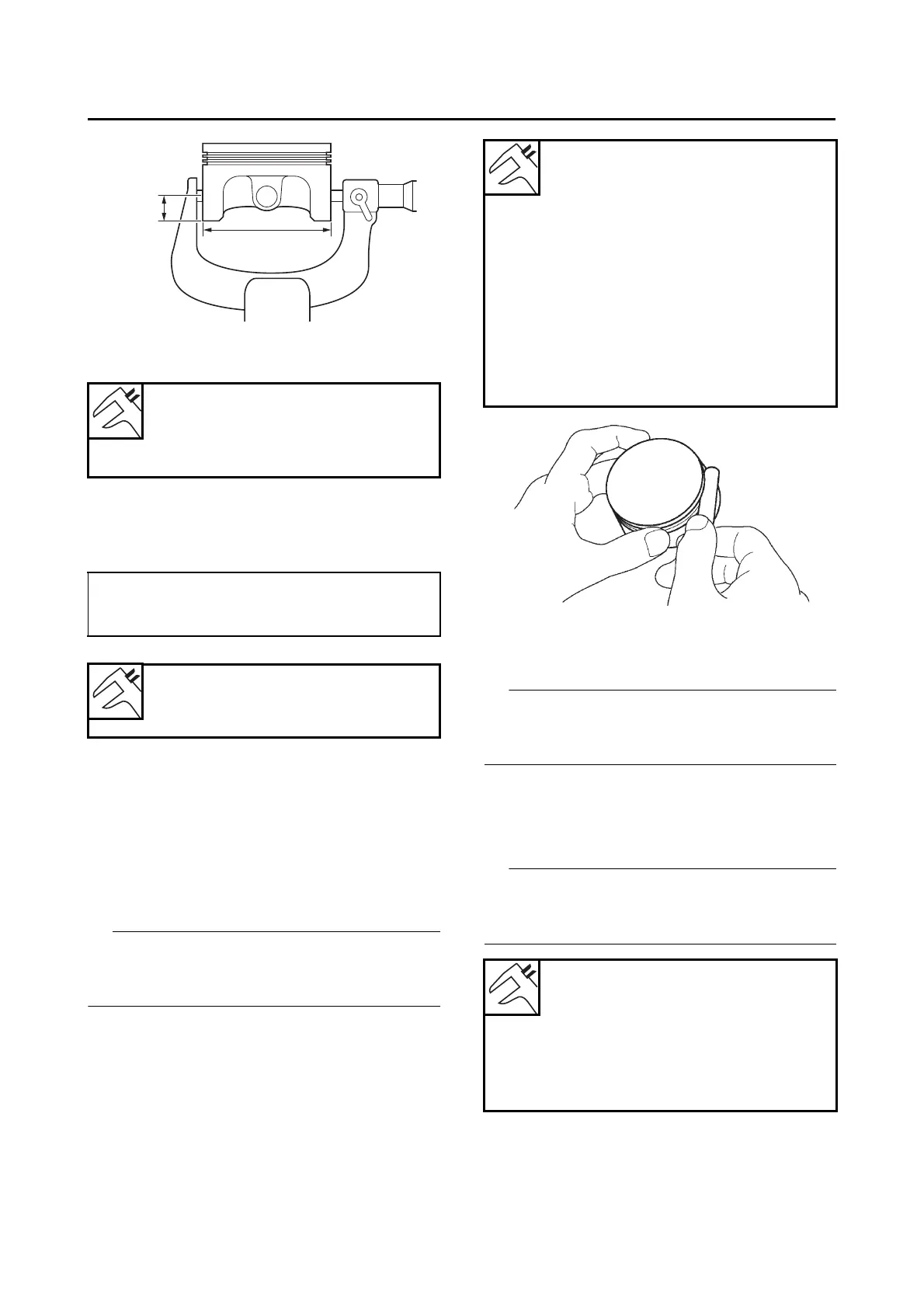

2. Install:

• Piston ring

(into the cylinder)

Use the piston crown to level the piston ring near

the bottom of the cylinder where the cylinder

wear is lowest.

3. Measure:

• Piston ring end gap

Out of specification Replace the piston ring

set.

The oil ring expander spacer’s end gap cannot

be measured. If the oil ring rail’s gap is exces-

sive, replace all three piston rings.

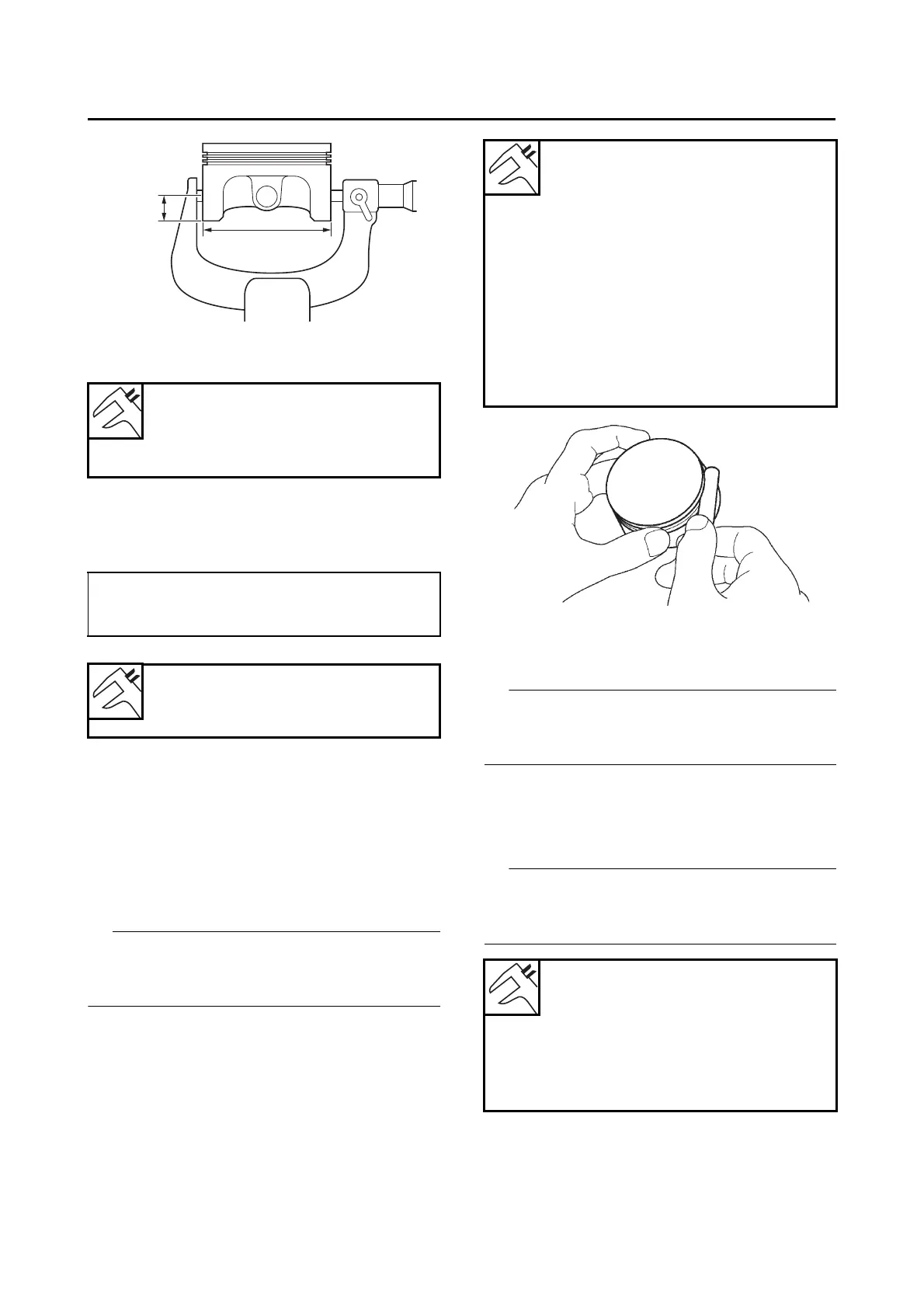

a. 8.0 mm (0.31 in) from the bottom edge of

the piston

Piston

Diameter

69.975–69.990 mm

(2.7549–2.7555 in)

Piston-to-cylinder clearance =

Cylinder bore -

Piston skirt diameter

Piston-to-cylinder clearance

0.010–0.035 mm (0.0004–0.0014

in)

Piston ring

Top ring

Ring side clearance

0.030–0.065 mm

(0.0012–0.0026 in)

Side clearance limit

0.115 mm (0.0045 in)

2nd ring

Ring side clearance

0.020–0.055 mm

(0.0008–0.0022 in)

Side clearance limit

0.115 mm (0.0045 in)

Piston ring

Top ring

End gap limit

0.50 mm (0.0197 in)

2nd ring

End gap limit

0.85 mm (0.0335 in)

Loading...

Loading...