20-12 Art: 714382-00D Rev. Date: 02/20/06

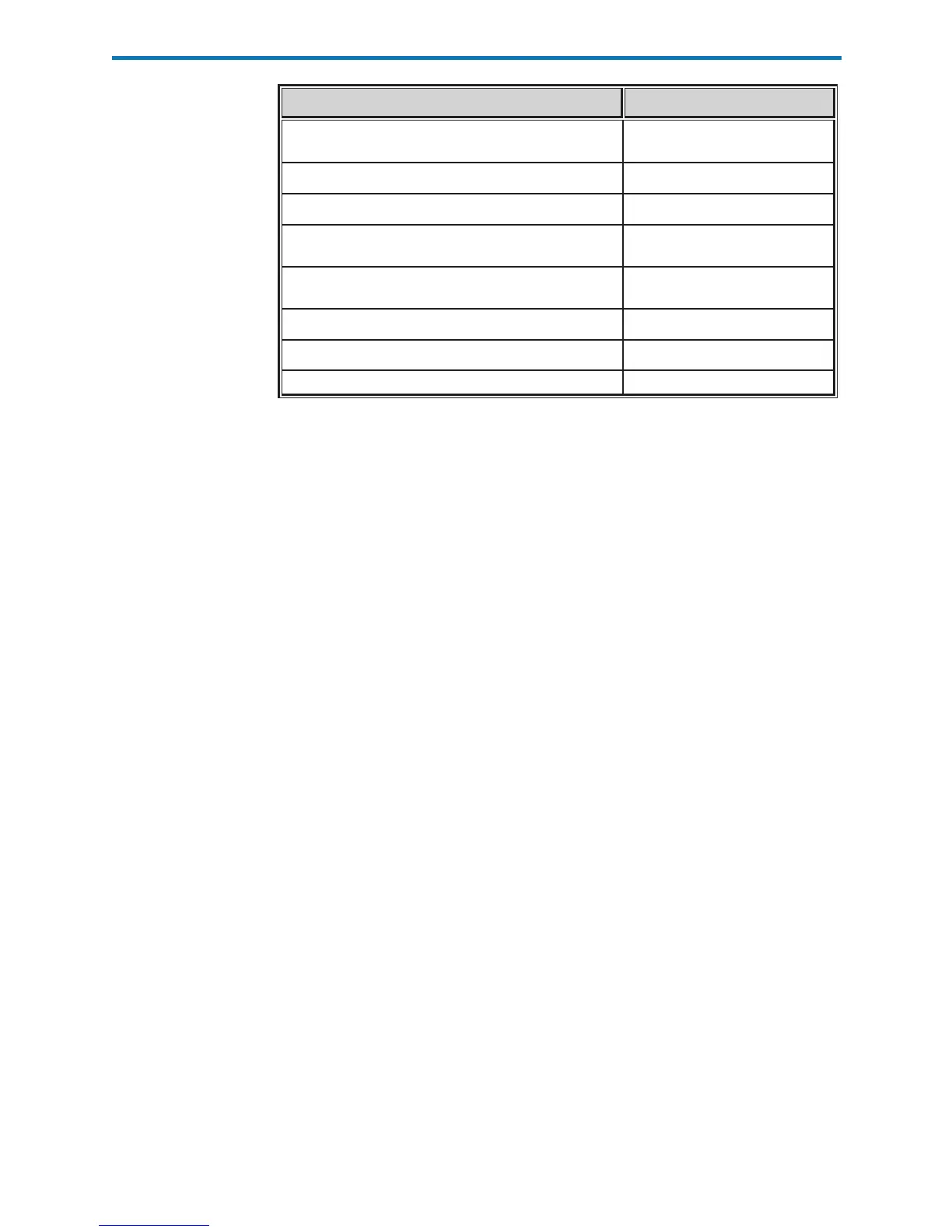

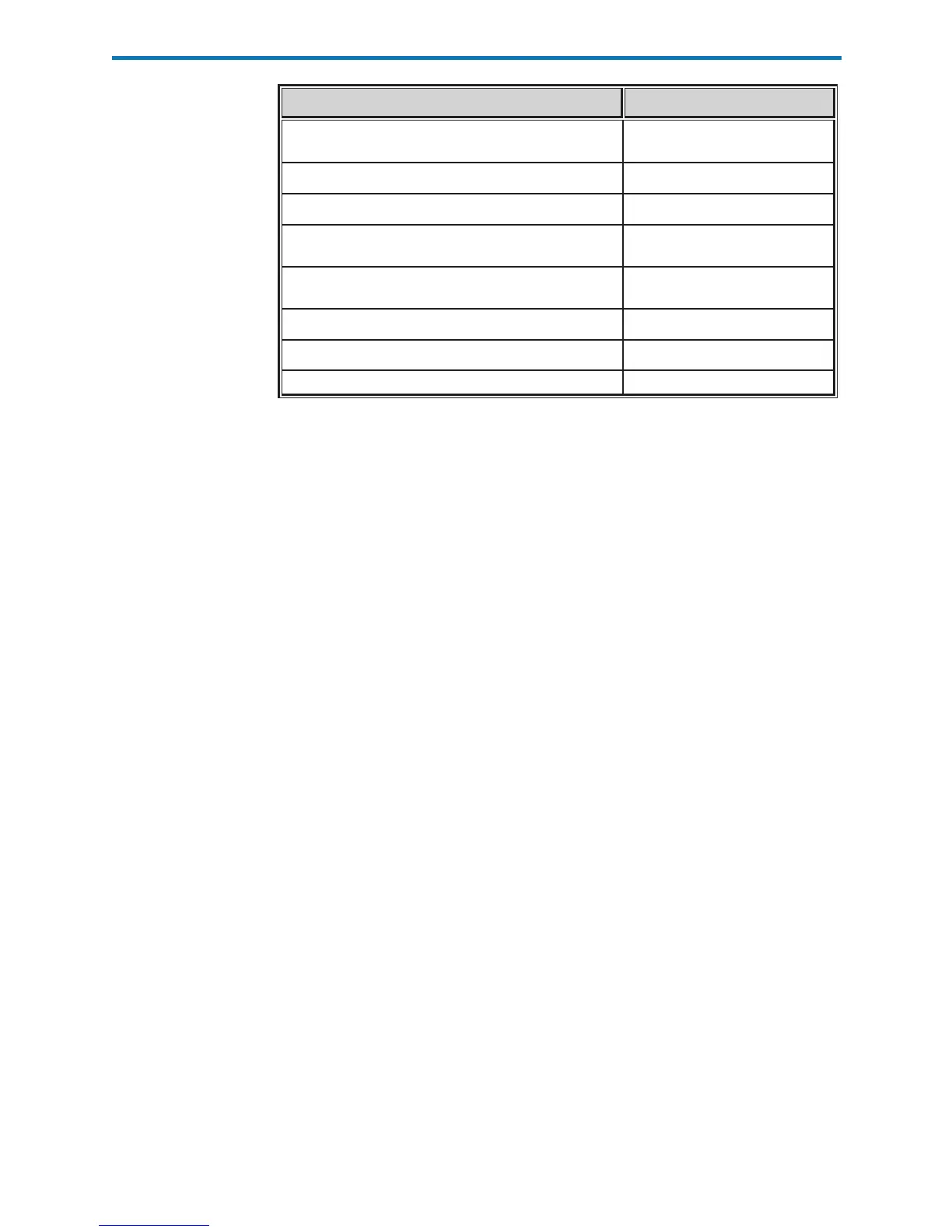

Operator Sample

Handling/Cartridge

Verification When Verified

Verify the cartridge inserted has not been previously used Every cartridge use

Verify the calibrant pack has not prematurely ruptured Every cartridge use

Verify the electronic contact pads are dry and uncontaminated Every cartridge use

Verify the proper amount of sample was placed into the sample

chamber

Every cartridge use

Verify the sample was properly positioned within the sample

chamber

Every cartridge use

Verify the sample is free of included bubbles Every cartridge use

Verify the sample is not clotted Every cartridge use

Verify the sample chamber is properly sealed with the snap closure Every cartridge use

Validating the

Performance of the

i-STAT System

Until recently, regulations and laboratory accreditation standards specified the

use of traditional quality control regimens, including the daily use of liquid

“control” materials.

As new technologies such as the i-STAT System have become available, the

community has recognized the limitations of relying upon traditional regimens,

prompting various regulatory and accreditation organizations to modify their

standards accordingly.

Many of the newly drafted regulations and accreditation standards recognize

the danger of denoting specific methods of achieving an effective quality

control regimen. Additionally, specific methods cannot anticipate future

technological changes, so many of the regulatory and accreditation

organizations are changing their standards to place the responsibility of

establishing and validating the quality system a laboratory employs on the

laboratory director.

Quality control regimens should be established using information from the

manufacturer and scientific literature.

It is important to validate the performance of the i-STAT System and the

recommended quality control regimen to develop personal confidence in

our approach to the challenges of putting a diagnostic device in the hands of

individuals untrained in laboratory science.

Some of the regulatory and accreditation organizations recommend the daily

use of liquid “control” materials for the first month of use, slowly stepping back

the frequency as a database of performance information increases confidence

levels. The number of lots of materials examined should also be considered

when determining a validation protocol.

Loading...

Loading...