Parameter

structure

Keypad and

display

Parameter

x.00

Parameter

description format

Advanced parameter

descriptions

Macros

Serial comms

protocol

Electronic

nameplate

Performance RFC mode

Menu 4

Unidrive SP Advanced User Guide 103

Issue Number: 10 www.controltechniques.com

Open-loop

These parameters control the proportional and integral gains of the current controller used in the open loop drive. As already mentioned the current

controller either provides current limits or closed loop torque control by modifying the drive output frequency. The control loop is also used in its torque

mode during mains loss, or when the controlled mode standard ramp is active and the drive is decelerating, to regulate the flow of current into the

drive. Although the default settings have been chosen to give suitable gains for less demanding applications it may be necessary for the user to adjust

the performance of the controller. The following is a guide to setting the gains for different applications.

Current limit operation

The current limits will normally operate with an integral term only, particularly below the point where field weakening begins. The proportional term is

inherent in the loop. The integral term must be increased enough to counter the effect of the ramp which is still active even in current limit. For

example, if the drive is operating at constant frequency and is overloaded the current limit system will try to reduce the output frequency to reduce the

load. At the same time the ramp will try to increase the frequency back up to the demand level. If the integral gain is increased too far the first signs of

instability will occur when operating around the point where field weakening begins. These oscillations can be reduced by increasing the proportional

gain. A system has been included to prevent regulation because of the opposite actions of the ramps and the current limit. This can reduce the actual

level that the current limit becomes active by 12.5%. This still allows the current to increase up to the current limit set by the user. However the current

limit flag (Pr 10.09) could become active up to 12.5% below the current limit depending on the ramp rate used.

Torque control

Again the controller will normally operate with an integral term only, particularly below the point where field weakening begins. The first signs of

instability will appear around base speed, and can be reduced by increasing the proportional gain. The controller can be less stable in torque control

mode rather than when it is used for current limiting. This is because load helps to stabilise the controller, and under torque control the drive may

operate with light load. Under current limit the drive is often under heavy load unless the current limits are set at a low level.

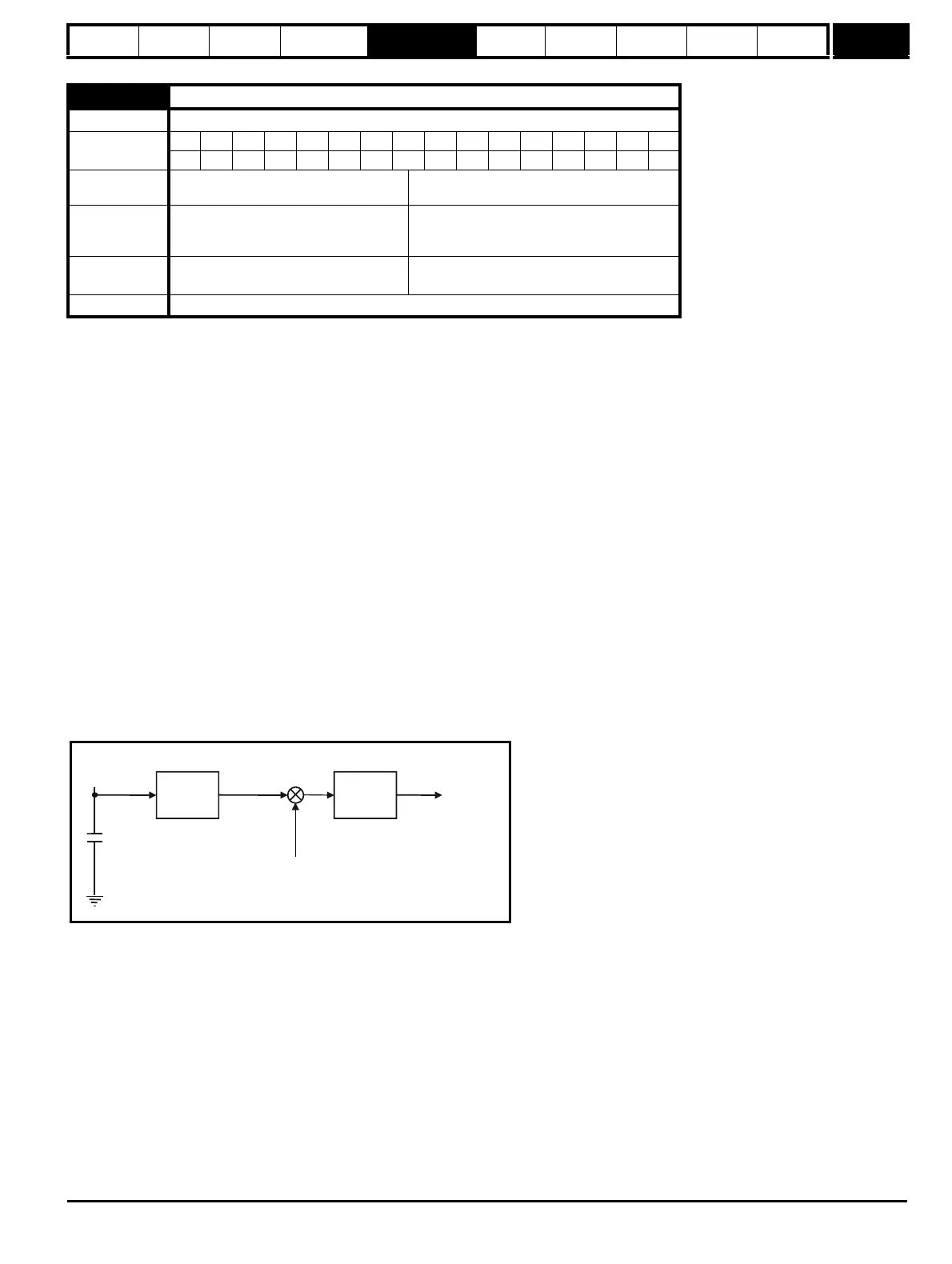

Mains loss and controlled standard ramp

The DC bus voltage controller becomes active if mains loss detection is enabled and the drive supply is lost or controlled standard ramp is being used

and the machine is regenerating. The DC bus controller attempts to hold the DC bus voltage at a fixed level by controlling the flow of current from the

drive inverter into its DC bus capacitors. The output of the DC bus controller is a current demand which is fed into the current PI controller as shown

in the following diagram.

Although it is not usually necessary the DC bus voltage controller can be adjusted with Pr 5.31. However, it may often be necessary to adjust the

current controller gains to obtain the required performance. If the gains are not suitable it is best to set up the drive in torque control first. Set the gains

to a value that does not cause instability around the point at which field weakening occurs. Then revert back to open loop speed control in standard

ramp mode. To test the controller the supply should be removed while the motor is running. It is likely that the gains can be increased further if

required because the DC bus voltage controller has a stabilising effect, provided that the drive is not required to operate in torque control mode.

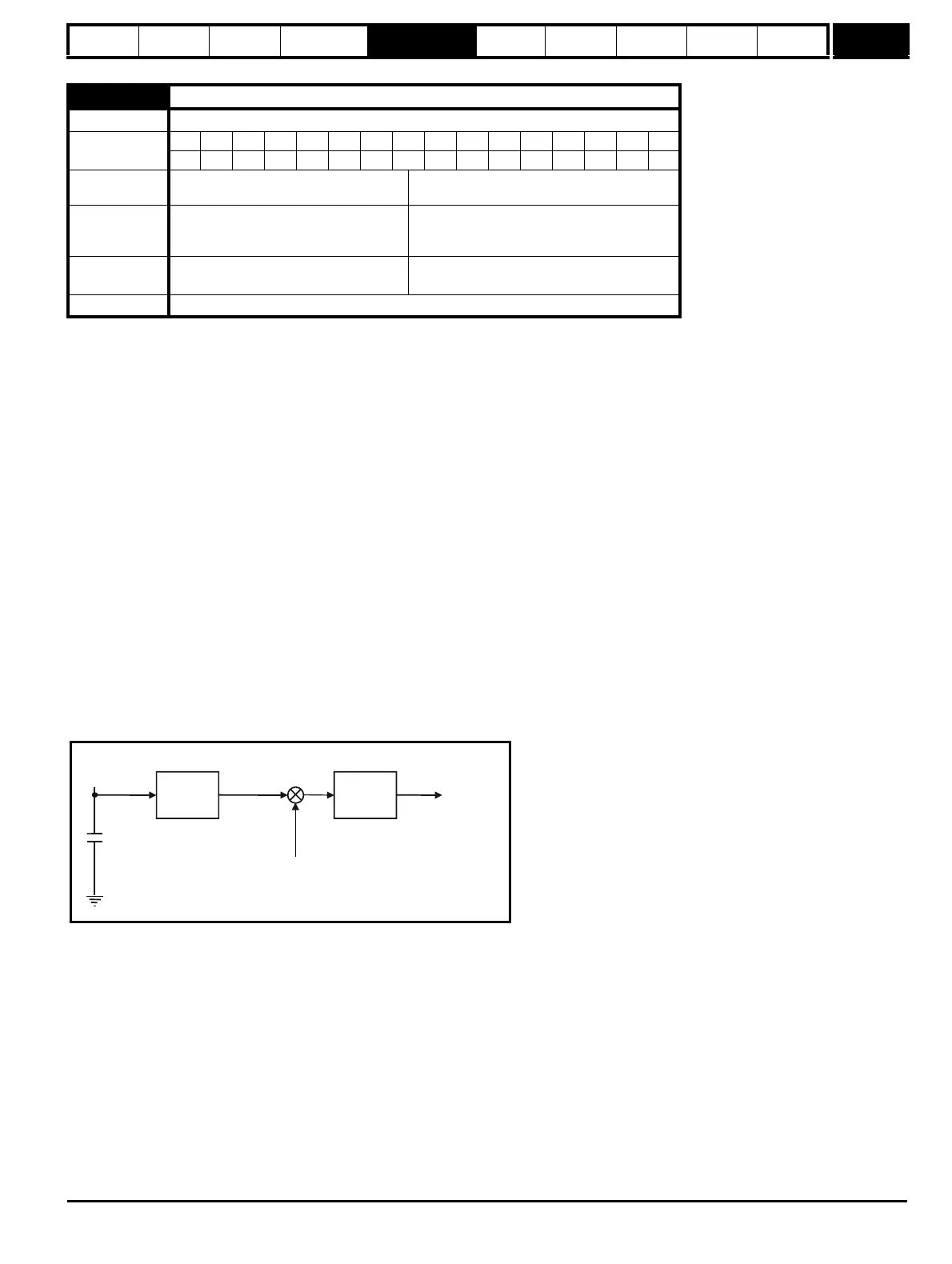

4.14 Current controller Ki gain

Drive modes Open-loop, Closed-loop vector, Servo, Regen

Coding

Bit SP FI DE Txt VM DP ND RA NC NV PT US RW BU PS

111

Range

Open-loop, Closed-loop vector, Servo,

Regen

0 to 30,000

Default

Drive voltage rating:

Open-loop,

Closed-loop vector, Servo, Regen

200V 400V 575V 690V

40 40 40 40

1,000 2,000 2,400 3,000

Second motor

parameter

Closed-loop vector, Servo Pr 21.23

Update rate Background read

DC Bus

voltage

controller

P Pr

4.13

I Pr

4.14

Frequency

reference

Active current

DC Bus

capacitor

Current

demand

Loading...

Loading...