Parameter

structure

Keypad and

display

Parameter x.00

Parameter

description format

Advanced parameter

descriptions

Macros

Serial comms

protocol

Electronic

nameplate

Performance RFC mode

406 Unidrive SP Advanced User Guide

www.controltechniques.com Issue Number: 10

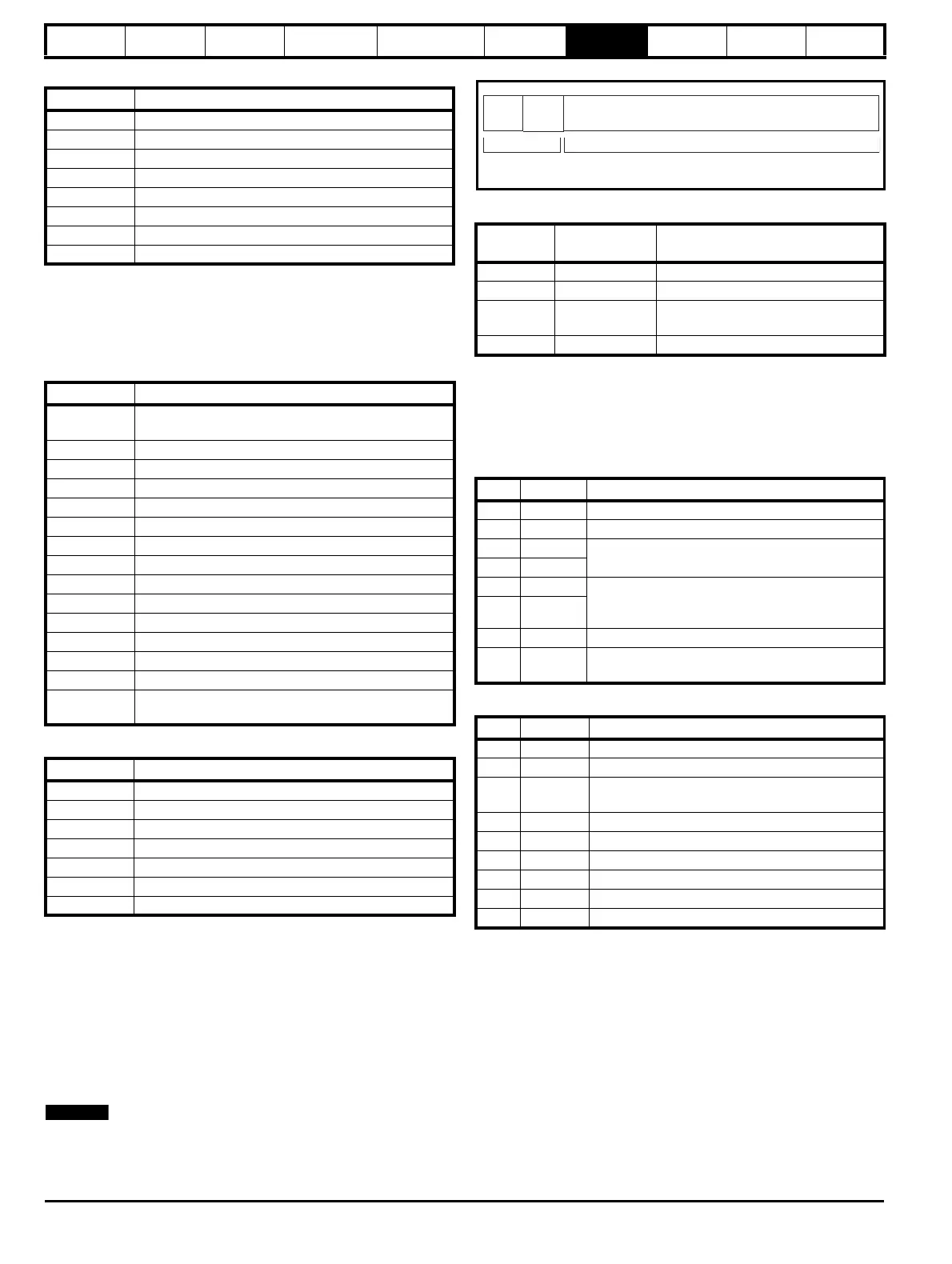

Table 7-6 Slave response

FC23 Read/Write multiple

Writes and reads two contiguous arrays of registers. The slave imposes

an upper limit on the number of registers which can be written. If this is

exceeded the slave will discard the request and the master will time out.

Table 7-7 Master request

Table 7-8 Slave response

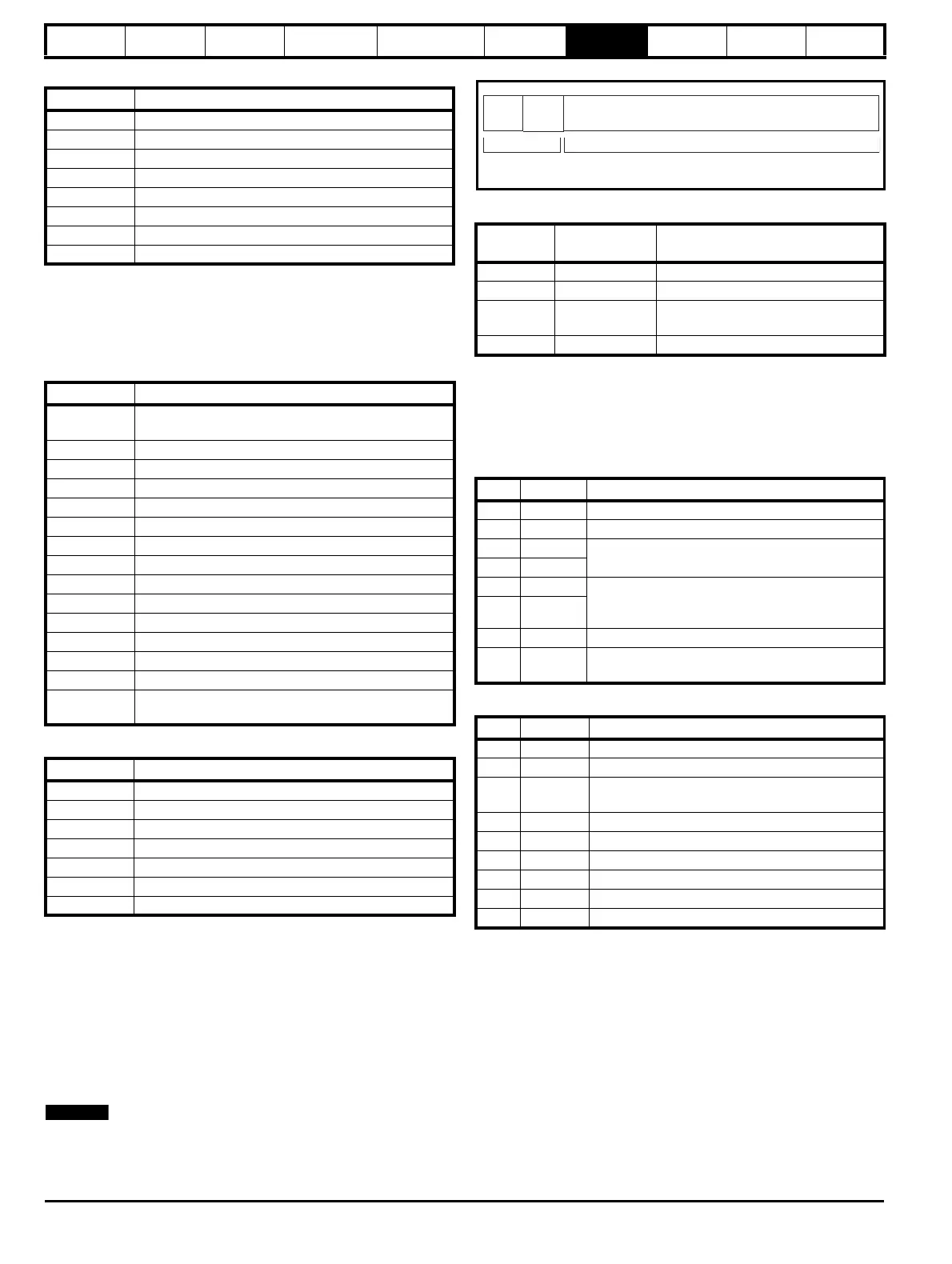

7.2.7 Extended data types

Standard MODBUS registers are 16bit and the standard mapping maps

a single #X.Y parameter to a single MODBUS register. To support 32bit

data types (integer and float) the MODBUS multiple read and write

services are used to transfer a contiguous array of 16bit registers.

Slave devices typically contain a mixed set of 16bit and 32bit registers.

To permit the master to select the desired 16bit or 32bit access the top

two bits of the register address are used to indicate the selected data

type.

The selection is applied for the whole block access.

The 2bit type field selects the data type according to the table below:

If a 32bit data type is selected then the slave uses two consecutive 16bit

MODBUS registers (in 'big endian'). The master must also set the

correct 'number of 16bit registers'.

Example, read #20.21 through #20.24 as 32bit parameters using FC03

from node 8:

Table 7-9 Master request

Table 7-10 Slave response

Reads when actual parameter type is different from selected

The slave will send the least significant word of a 32 bit parameter if that

parameter is read as part of a 16 bit access.

The slave will sign extend the least significant word if a 16 bit parameter

is accessed as a 32 bit parameter. The number of 16 bit registers must

be even during a 32 bit access.

Example, If #1.28 is a 32 bit parameter with a value of 0x12345678,

#1.29 is a signed 16 bit parameter with a value of 0xABCD, and #1.30 is

a signed 16 bit parameter with a value of 0x0123.

Byte Description

0 Slave source node address

1 Function code 0x10

2 Start register address MSB

3 Start register address LSB

4 Number of 16bit registers written MSB

5 Number of 16bit registers written LSB

6 CRC LSB

7 CRC MSB

Byte Description

0

Slave node address 1 through 247,

0 is global

1 Function code 0x17

2 Start register address to read MSB

3 Start register address to read LSB

4 Number of 16bit registers to read MSB

5 Number of 16bit registers to read LSB

6 Start register address to write MSB

7 Start register address to write LSB

8 Number of 16bit registers to write MSB

9 Number of 16bit registers to write LSB

10 Length of register data to write (in bytes)

11 Register data 0 MSB

12 Register data 0 LSB

11+byte count CRC LSB

12+byte

count

CRC MSB

Byte Description

0 Slave source node address

1 Function code 0x17

2 Length of register data in read block (in bytes)

3 Register data 0 MSB

4 Register data 0 LSB

3+byte count CRC LSB

4+byte count CRC MSB

Type field

bits 15-14

Selected data

type

Comments

00 INT16 backward compatible

01 INT32

10 Float32

IEEE754 standard

Not supported on all slaves

11 Reserved

Byte Value Description

0 0x08 Slave destination node address

1 0x03 FC03 multiple read

20x47

Start register address #20.21

(16384 + 2021 - 1) = 18404 = 0x47E4

30xE4

4 0x00 Number of 16bit registers to read

#20.21 through #20.24 is 4x32bit registers =

8x16bit registers

50x08

6 CRC LSB

7

CRC

MSB

Byte Value Description

0 0x08 Slave destination node address

1 0x03 FC03 multiple read

20x10

Length of data (bytes) = 4x32bit registers =

16bytes

3-6 #20.21 data

7-10 #20.22 data

11-14 #20.23 data

15-18 #20.24 data

19 CRC LSB

20 CRC MSB

bit 15

TYP1

bits 0 - 13

Type select Parameter address

X x 100+Y-1

bit 14

TYP0

Loading...

Loading...