Menu 3

All modes

Parameter

structure

Keypad and

display

Parameter

x.00

Parameter

description format

Advanced parameter

descriptions

Macros

Serial comms

protocol

Electronic

nameplate

Performance RFC mode

80 Unidrive SP Advanced User Guide

www.controltechniques.com Issue Number: 10

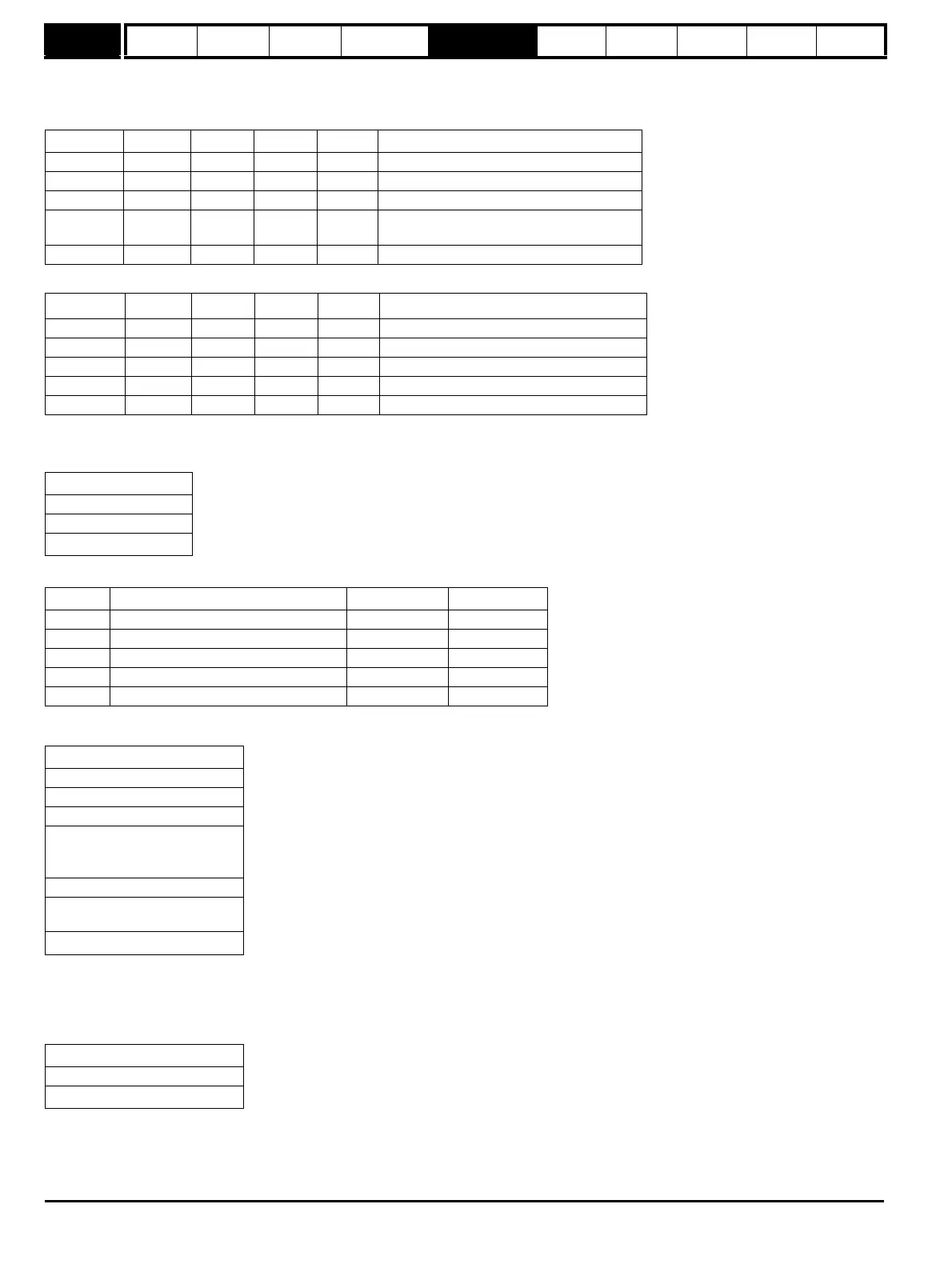

Example of Hiperface transfer: Delete data field

Transfer the "delete data field" message to the encoder comms buffer by writing the sequence of words shown in the table below to Pr 90.22. A check

should be carried out before each word is written to ensure that the parameter is zero (i.e. the drive has taken any previous data).

The response from the encoder is a follows.

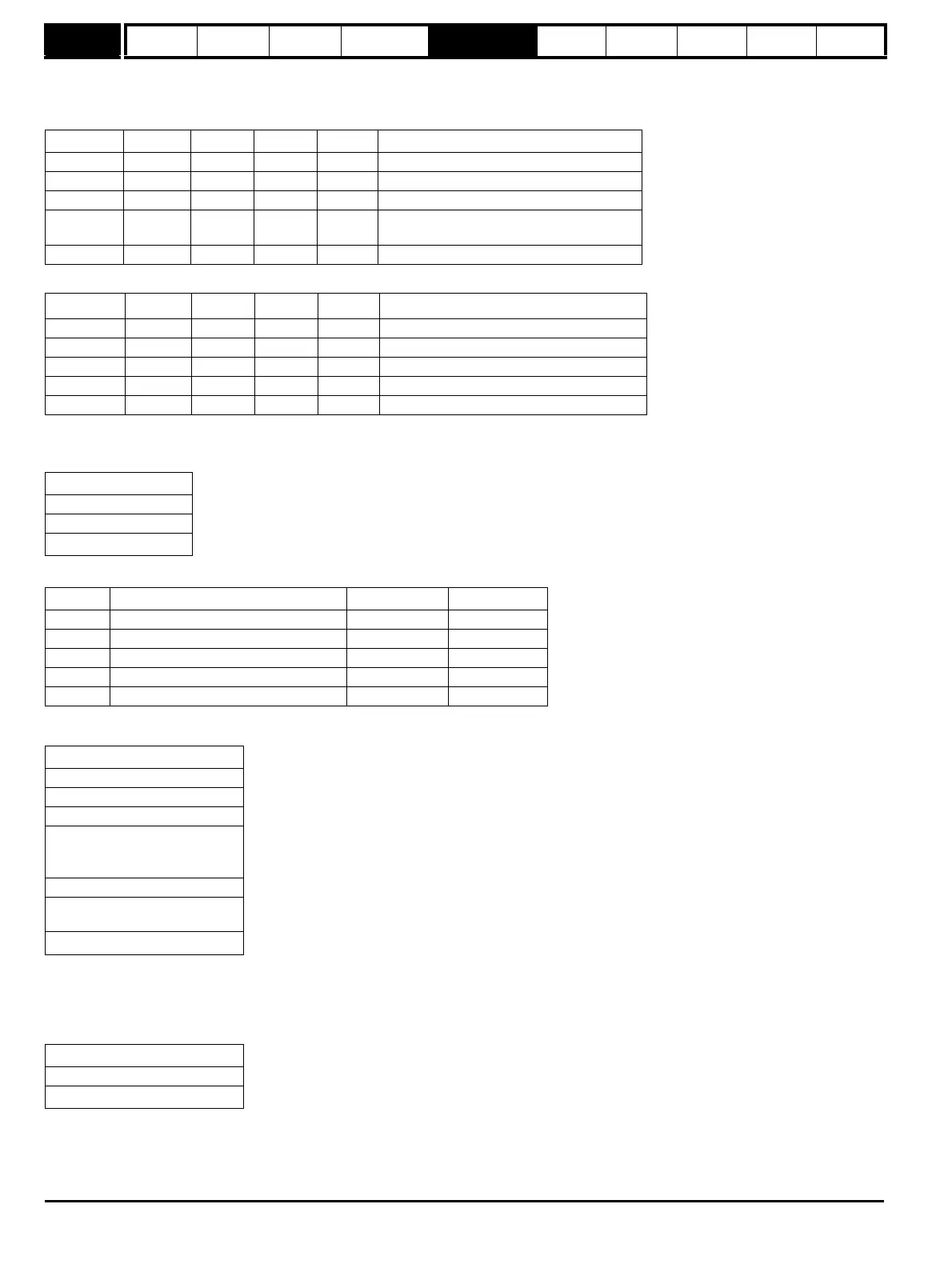

SC.EnDat

The Heidenhain EnDat protocol is a synchronous protocol using the following command message format (drive to encoder).

The following commands are supported:

The following is an example of the response when the Encoder to send position command is used (encoder to drive).

The example shown above is for an encoder with 12 bits representing the turns and 13 bits representing the position within a turn. The position

command only requires one byte to be sent to the encoder. Bits 14 and 13 can both be set in the transmit register if required to indicate that this is

both the first and last byte of the message.

If any other command is used then the response is as follows (encoder to drive).

Example of EnDat transfer: Read position

Disable drive encoder position check by setting Pr 90.21 to one. This should be set back to zero at the end of the transfer if encoder position checking

is required.

Bit 15 Bit 14 Bit 13 Data

0xa0ff 1 0 1 0xff Broadcast message so address = 0xff

0x804d 1 0 0 0x4d Create data field command

0x8002 1 0 0 0x02 Data field 2

0x8065 1 0 0 0x65

Status of data existing data field 2 with bit 7

set to zero

0x8055 1 1 0 0x55 Code for data field at default of 0x55

Bit 15 Bit 14 Bit 13 Data

0x8040 1 0 0 0x40 Encoder address

0x8042 1 0 0 0x4d Create data field command

0x8003 1 0 0 0x02 Data field 2

0x8059 1 0 0 0x65 Status of the data field before delete

0x8063 1 1 0 0x78 Checksum

Command

1

st

byte

Address

Data (LSB)

Data (MSB)

4

th

byte

Code Command Address Data

0x00 Encoder to send position Don’t care Don’t care

0x01 Selection of memory area MRS code Don’t care

0x03 Encoder to receive parameter Address Data

0x04 Encoder to send parameter Address Don’t care

0x05 Encoder to receive reset Don’t care Don’t care

LS byte

1

st

byte

Bits 7-0 = 0

Bits 7-0 = 0

Bits 7-0 = 0

Bits 7-0 = 0

Bits 5-0 = 0

Bit 6 = Alarm bit

Bit 7 = Bit 0 of position

Bits 7-0 = Bits 8-1 of position

Bits 3-0 = Bits 12-9 of position

Bits 7-4 = Bits 3-0 of turns

MS byte

8

th

byte

Bits 7-0 = Bits 11-4 of turns

Address

1

st

byte

Data (LSB)

Data (MSB)

3

rd

byte

Loading...

Loading...