Parameter

structure

Keypad and

display

Parameter x.00

Parameter

description format

Advanced parameter

descriptions

Macros

Serial comms

protocol

Electronic

nameplate

Performance RFC mode

18 Unidrive SP Advanced User Guide

www.controltechniques.com Issue Number: 10

4 Parameter description format

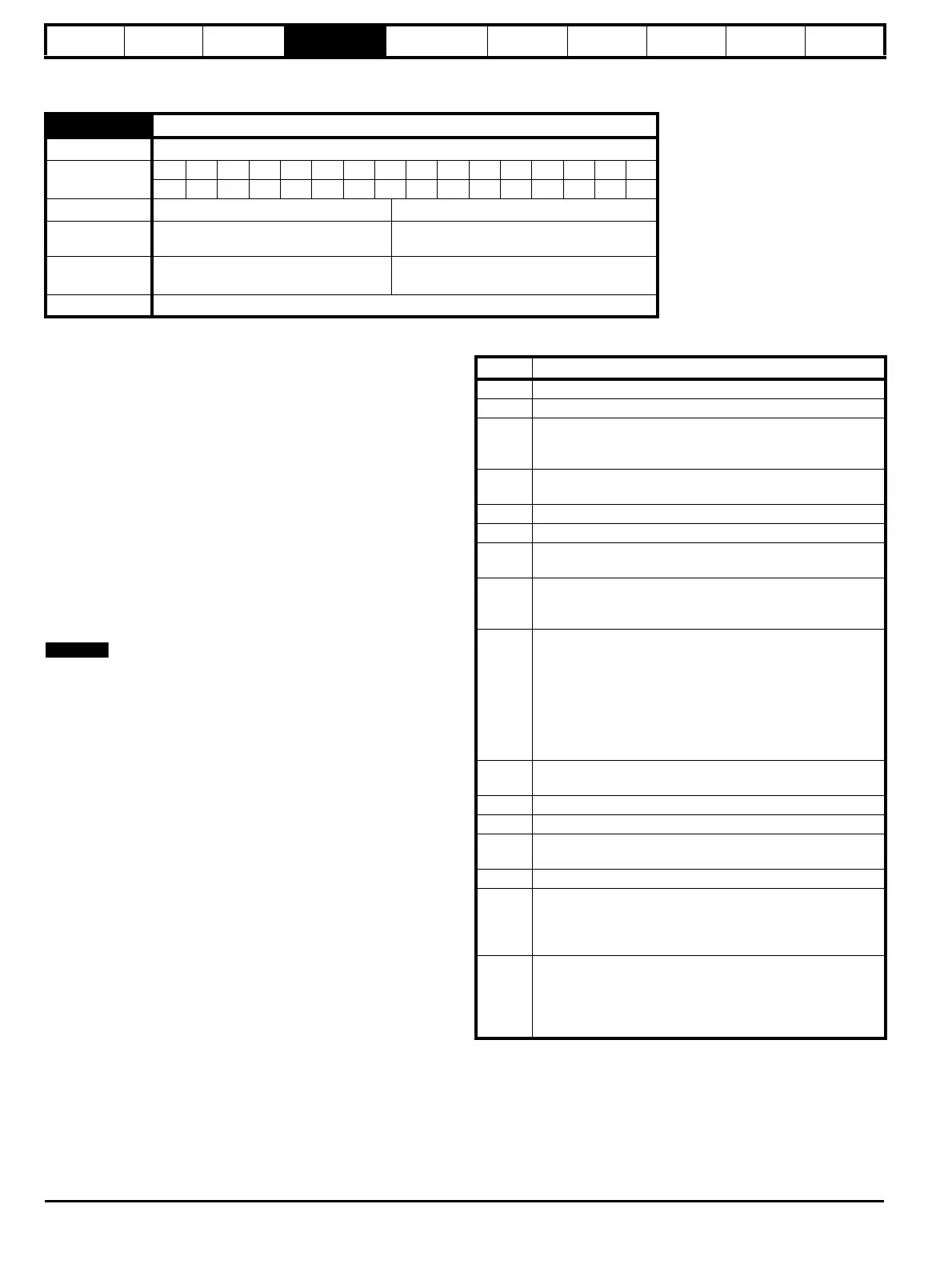

In the following sections descriptions are given for the advanced parameter set. With each parameter the following information block is given.

The top row gives the menu parameter number and name. The other

rows provide the following information.

Drive modes

The drive modes are the modes in which this parameter is accessible. If

the parameter is not present the parameter is skipped when accessing

from the keypad. The following types are possible.

Open-loop - The control strategy is V/F mode with fixed boost or open-

loop vector control.

Closed-loop vector - The control strategy is rotor flux oriented vector

control with closed-loop current operation for induction motors. The drive

can be operated with or without position feedback.

Servo - The control strategy is rotor flux oriented vector control with

closed-loop current operation for permanent magnet synchronous

motors. The drive must be operated with position feedback.

Regen - The drive operates as a PWM rectifier.

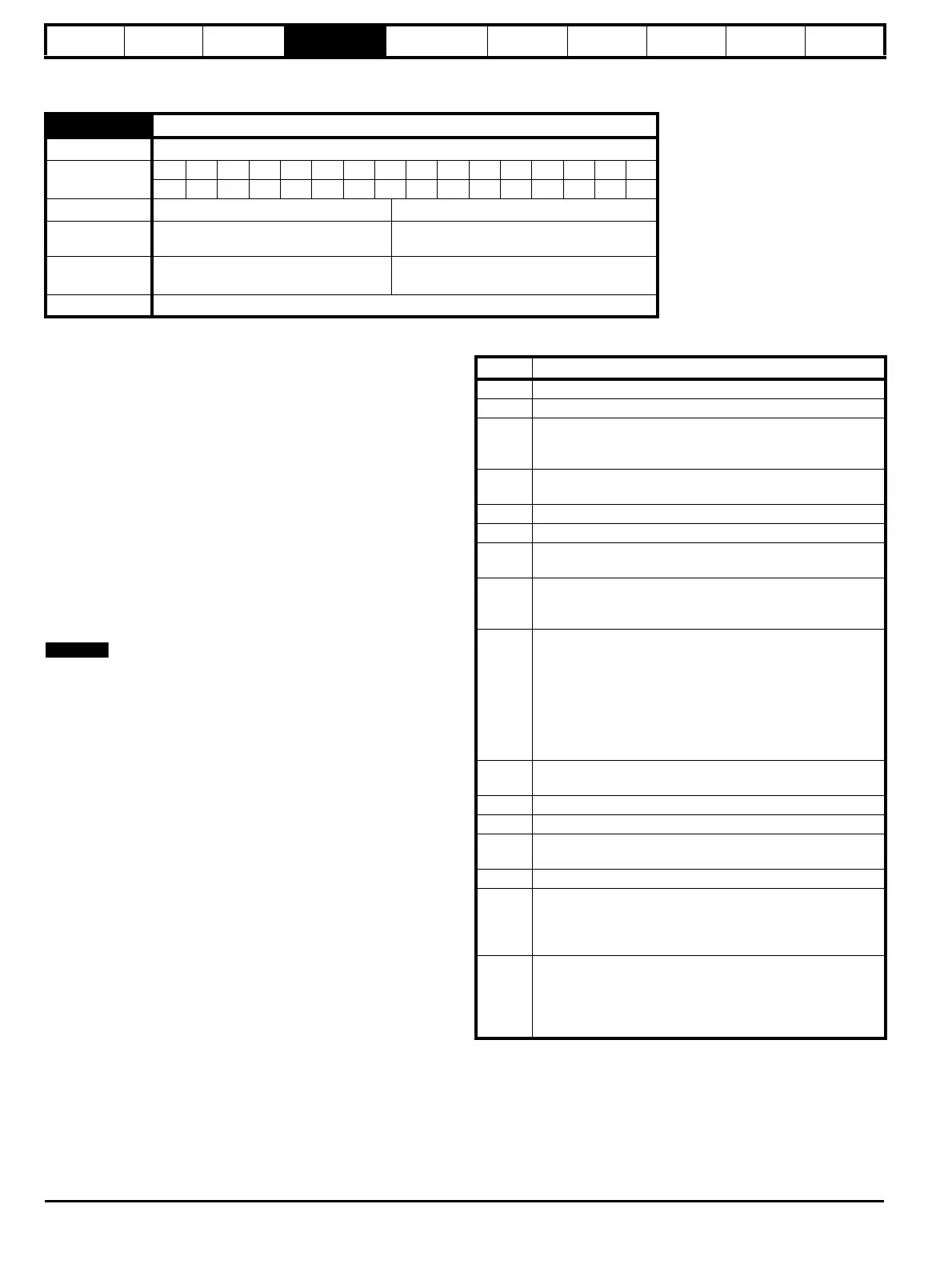

Coding

This guide will show all bit parameters (with the Bit coding), as having a

parameter range of "0 to 1", and a default value of either "0" or "1". This

reflects the value seen through serial communications. The bit

parameters will be displayed on the SM-Keypad or SM-Keypad Plus (if

used) as being "OFF" or "On" ("OFF"= 0, "On" = 1).

The coding defines the attributes of the parameter as follows:

5.11 Number of motor poles

Drive modes

Open-loop, Closed-loop vector, Servo

Coding

Bit SP FI DE Txt VM DP ND RA NC NV PT US RW BU PS

1111

Range Open-loop, Closed-loop vector, Servo 0 to 60 (Auto to 120 POLE)

Default

Open-loop, Closed-loop vector

Servo

0 (Auto)

3 (6 POLE)

Second motor

parameter

Open-loop, Closed-loop vector, Servo Pr 21.11

Update rate

Background read

Coding Attribute

Bit 1 bit parameter

SP Spare: not used

FI

Filtered: some parameters which can have rapidly changing

values are filtered when displayed on the drive keypad for

easy viewing.

DE

Destination: indicates that this parameter can be a

destination parameter.

Txt Text: the parameter uses text strings instead of numbers.

VM Variable maximum: the maximum of this parameter can vary.

DP

Decimal place: indicates the number of decimal places used

by this parameter.

ND

No default: when defaults are loaded (except when the drive

is manufactured or on EEPROM failure) this parameter is not

modified.

RA

Rating dependent: this parameter is likely to have different

values and ranges with drives of different voltage and current

ratings. Parameters with this attribute will not be transferred

to the destination drive by SMARTCARDs when the rating of

the destination drive is different from the source drive and the

file is a parameter file. However, with software V01.09.00 and

later the value will be transferred if only the current rating is

different and the file is a differences from default type file.

NC

Not copied: not transferred to or from SMARTCARDs during

copying.

NV Not visible: not visible on the keypad.

PT Protected: cannot be used as a destination.

US

User save: saved in drive EEPROM when the user initiates a

parameter save.

RW Read/write: can be written by the user.

BU

Bit default one/unsigned: Bit parameters with this flag set to

one have a default of one (all other bit parameters have a

default of zero. Non-bit parameters are unipolar if this flag is

one.

PS

Power-down save: parameter automatically saved in drive

EEPROM when the under volts (UV) trip occurs.

With software version V01.08.00 and later, power-down

save parameters are also saved in the drive when the user

initiates a parameter save.

Loading...

Loading...