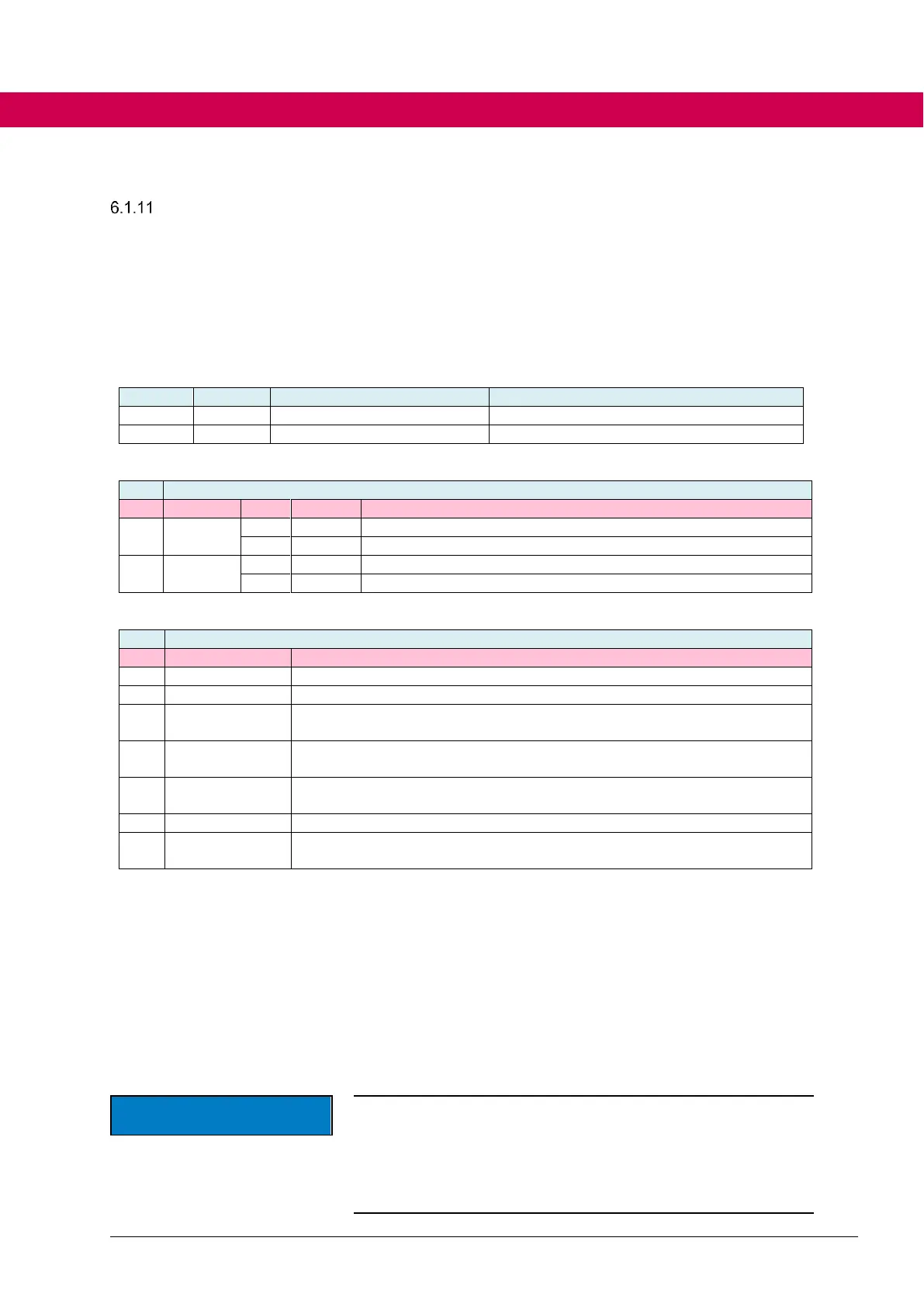

Store data in the encoder

Motor data can be read from an encoder with electronic type plate or written into

the encoder.

The values are stored in the encoder which were previously taken over with dr99

motordata control.

After reading or writing data, the ec status parameters should also be checked to

see if the encoder evaluation has still triggered errors or warnings.

Write or read data to the encoder.

State of the function of ec46.

ec46 and ec47 are only supported on encoder interface channel A.

Motor data are transferred from the encoder to the inverter.

Motor data are stored in the encoder.

Data are written to the encoder or read by the encoder.

The read data are not conform with a valid format for KEB. No data will be

transferred.

Data from the KEB-F5 Definition are found and transferred in the encoder.

Data for the enhanced format for H6 are found and transferred in the en-

coder.

No communication to the encoder possible.

(No encoder connected or interface not activated with ec16).

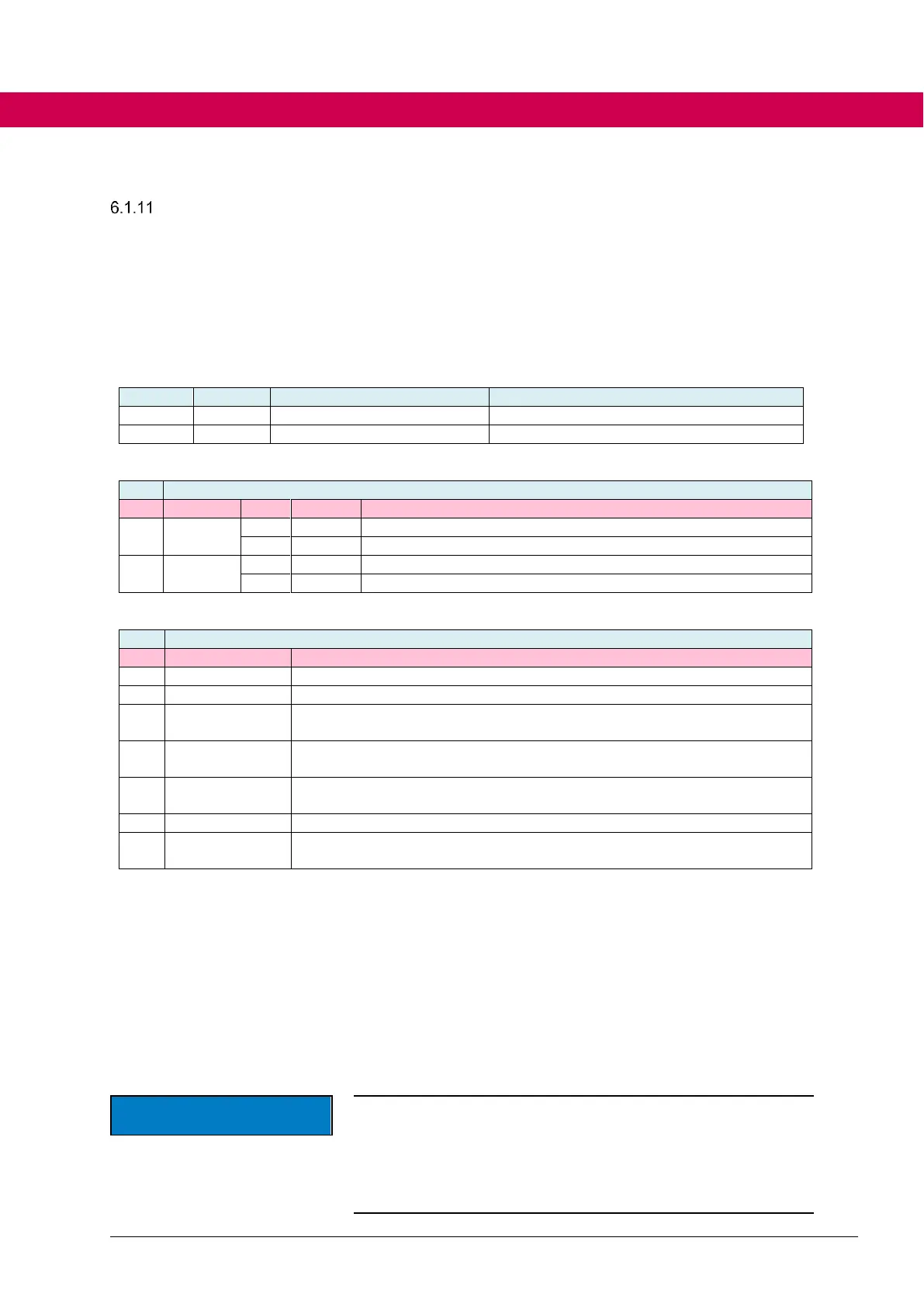

6.1.11.1 Format for the data in the encoder

The data in the following table are stored in the encoder depending on the motor

type. There are 2 different formats supported: "basic" = F5 format and "enhanced"

= for device generation 6 extended format

The extended (enhanced) format is always used when writing the data to the en-

coder. This is defined by way that the data of the F5 format (basic) remain accessi-

ble. An encoder written in the "enhanced" format can be read out with F5 devices.

➢ The rated motor voltage (dr05 rated voltage) is not stored in

the encoder for synchronous motors. If the value is unequal to

the default value of the inverter, dr05 must also be written,

since the limiting characteristic of the synchronous motor is

also dependent on the rated motor voltage of dr13 breakdown

torque and dr25 breakdown speed.

Loading...

Loading...