4.3 Errors and warnings

Errors

The status word displays via bit 3 (fault) when there is an error. The error type can

be determined via objects ru01 exception state and st01 error code:

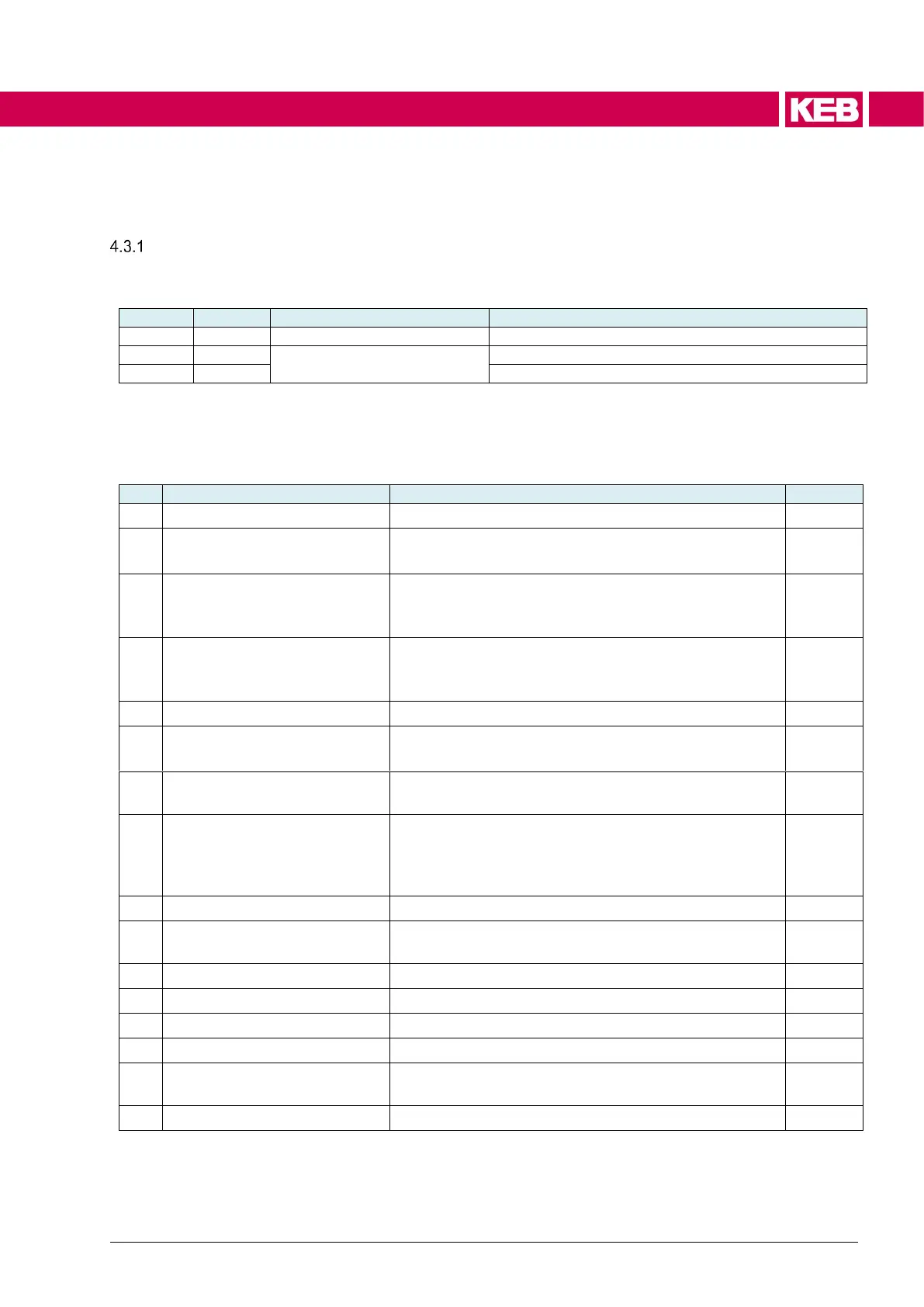

4.3.1.1 Error display in ru01

The faults are coded according to the following table:

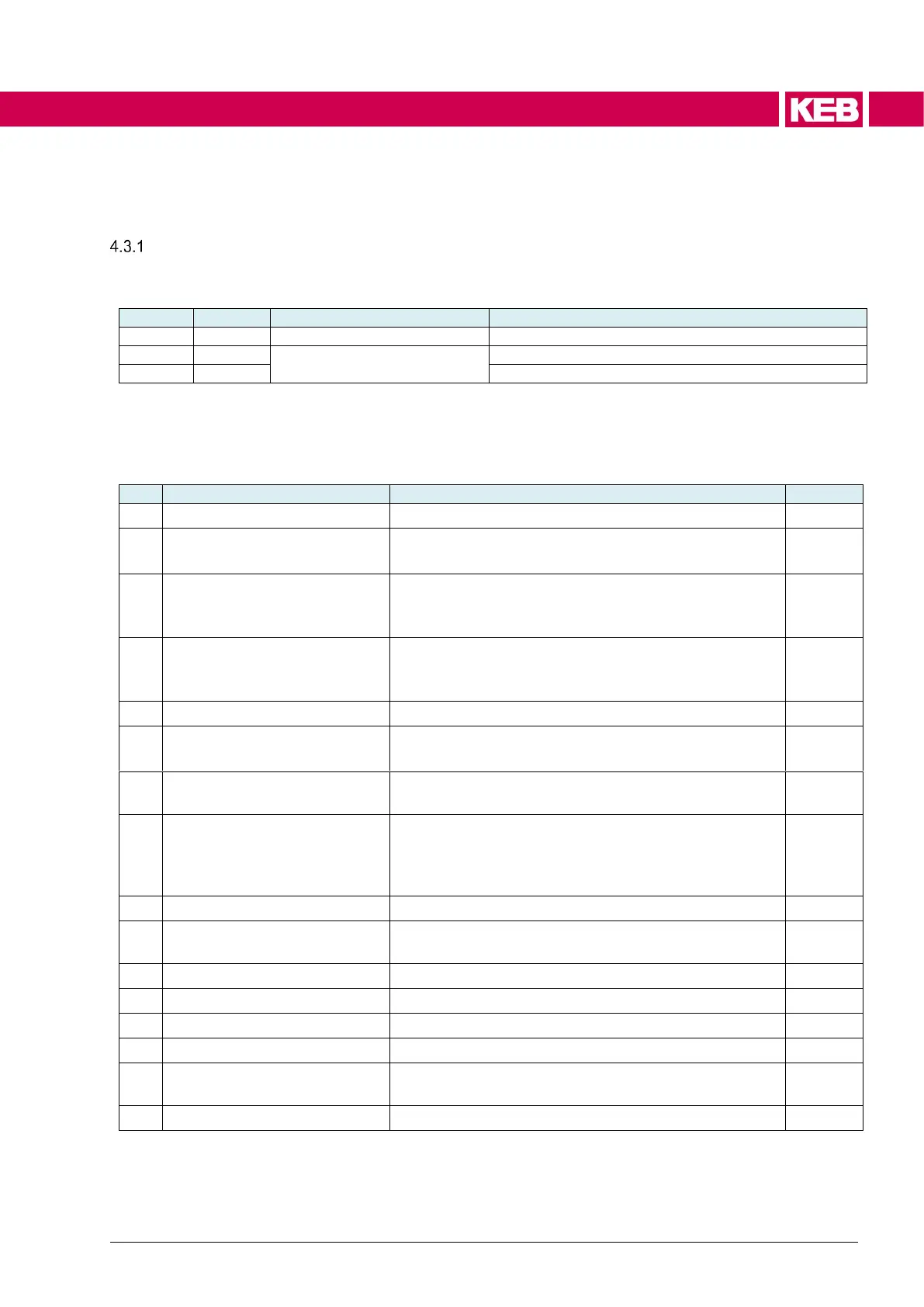

Overcurrent detection in the power unit has triggered

(e.g. short circuit, defective power module)

Exceeded overcurrent level on the control board

(e.g. Incorrect setting of the controller or the torque lim-

iting characteristic)

Overvoltage in DC link

(e.g. deceleration ramp too fast, braking resistor not

connected, braking transistor defective)

Module overload ( I

2

t ) => OL

(long-term mean current load is above 100%)

Reset of overload possible OL counter (ru29) < 50% of

the warning level

Module overload 2

(fast overload protection – defined by standstill continu-

ous current and short time current limit - has re-

sponded)

Overtemperature power components (heat sink)

Overtemperature power components decreased (tem-

perature 5° below OH level)

ERROR overheat internal PU

Overtemperature internal power unit

reset E. overheat intern PU

Overtemperature internal power unit decreased

electronic (software) motor protection has triggered

Error motor protection function can be reset

Temperature sensor in the motor (e.g. PTC or KTY)

has triggered

reset ERROR drive overheat

Overtemperature motor decreased

Loading...

Loading...