HYDRAULIC SYSTEM

B2650HSDC, B3350HSDC, WSM

7-S17

[4] SERVICING

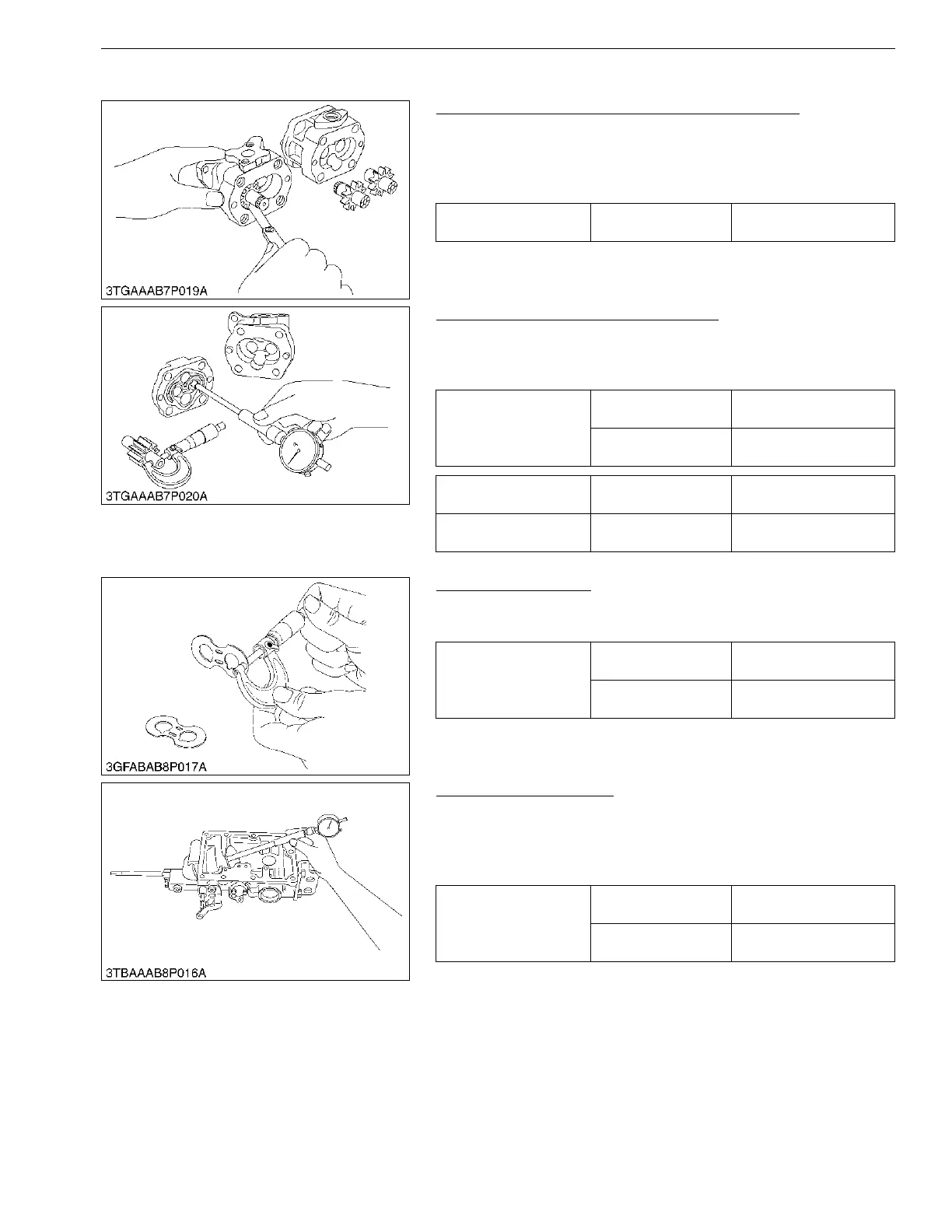

Clearance between Tip of Gear Tooth and Casing

1. Measure the clearance between gear and casing at several

points with feeler gauge.

2. If the clearance exceeds the allowable limit, replace the

assembly.

9Y1210822HYS0035US0

Clearance between Bushing and Shaft

1. Measure the shaft O.D. with an outside micrometer.

2. Measure the bushing I.D. with a cylinder gauge.

3. If the clearance exceeds the allowable limit, replace it.

9Y1210822HYS0036US0

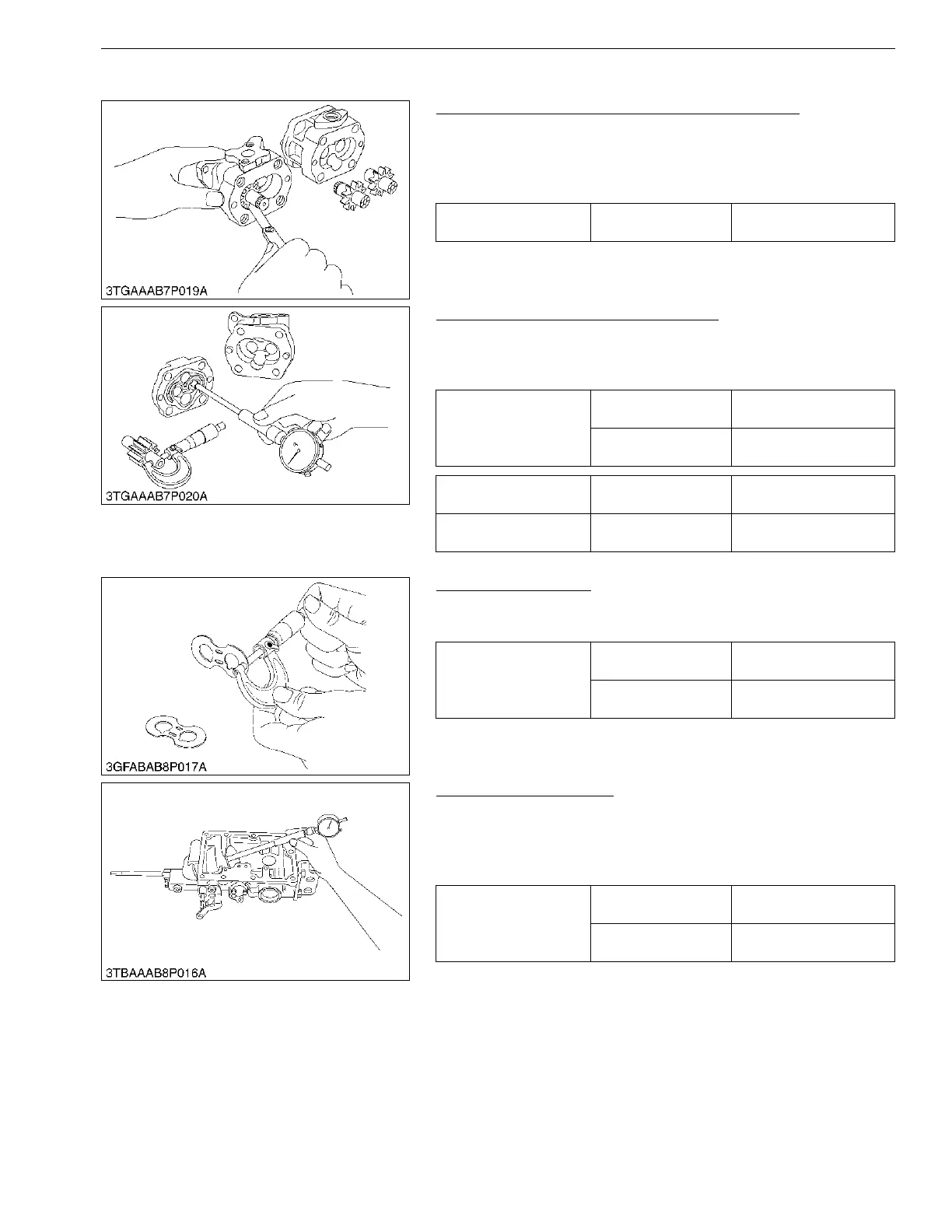

Side Plate Thickness

1. Measure the side plate thickness with an outside micrometer.

2. If the thickness is less than the allowable limit, replace it.

9Y1210822HYS0037US0

Hydraulic Cylinder Bore

1. Check the cylinder internal surface for scoring or damage.

2. Measure the cylinder I.D. with a cylinder gauge.

3. If the measurement exceeds the allowable limit, replace the

hydraulic cylinder block.

9Y1210822HYS0038US0

Clearance between tip of

gear tooth and casing

Allowable limit

0.15 mm

0.0059 in.

Clearance between

bushing and shaft

Factory specification

0.020 to 0.091 mm

0.00079 to 0.0035 in.

Allowable limit

0.12 mm

0.0047 in.

Shaft O.D. Factory specification

14.970 to 14.980 mm

0.58937 to 0.58976 in.

Bushing I.D. Factory specification

15.000 to 15.061 mm

0.59056 to 0.59295 in.

Side plate thickness

Factory specification

2.48 to 2.50 mm

0.0977 to 0.0984 in.

Allowable limit

2.40 mm

0.0945 in.

Cylinder I.D.

Factory specification

75.05 to 75.10 mm

2.955 to 2.956 in.

Allowable limit

75.15 mm

2.959 in.

Loading...

Loading...