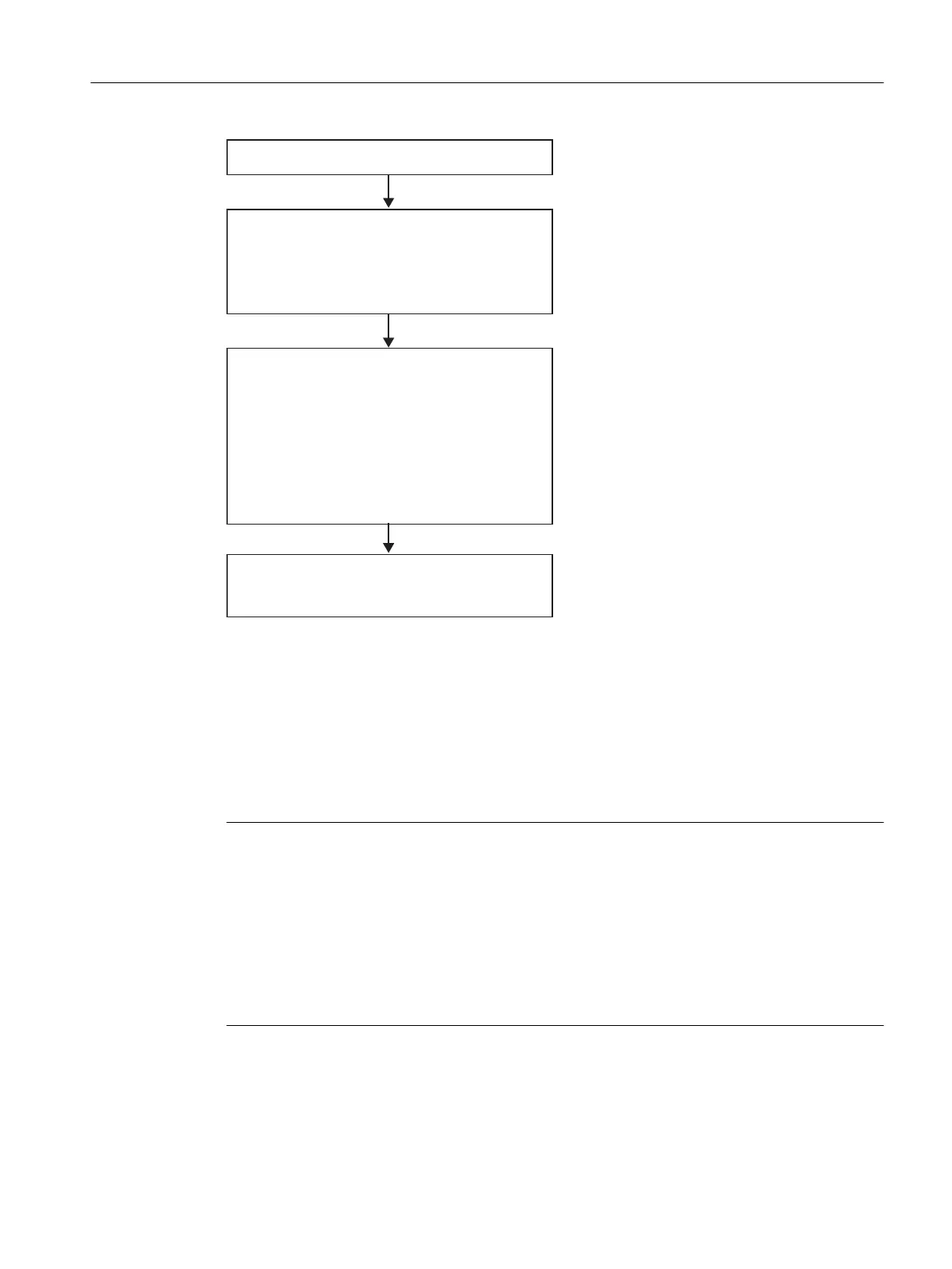

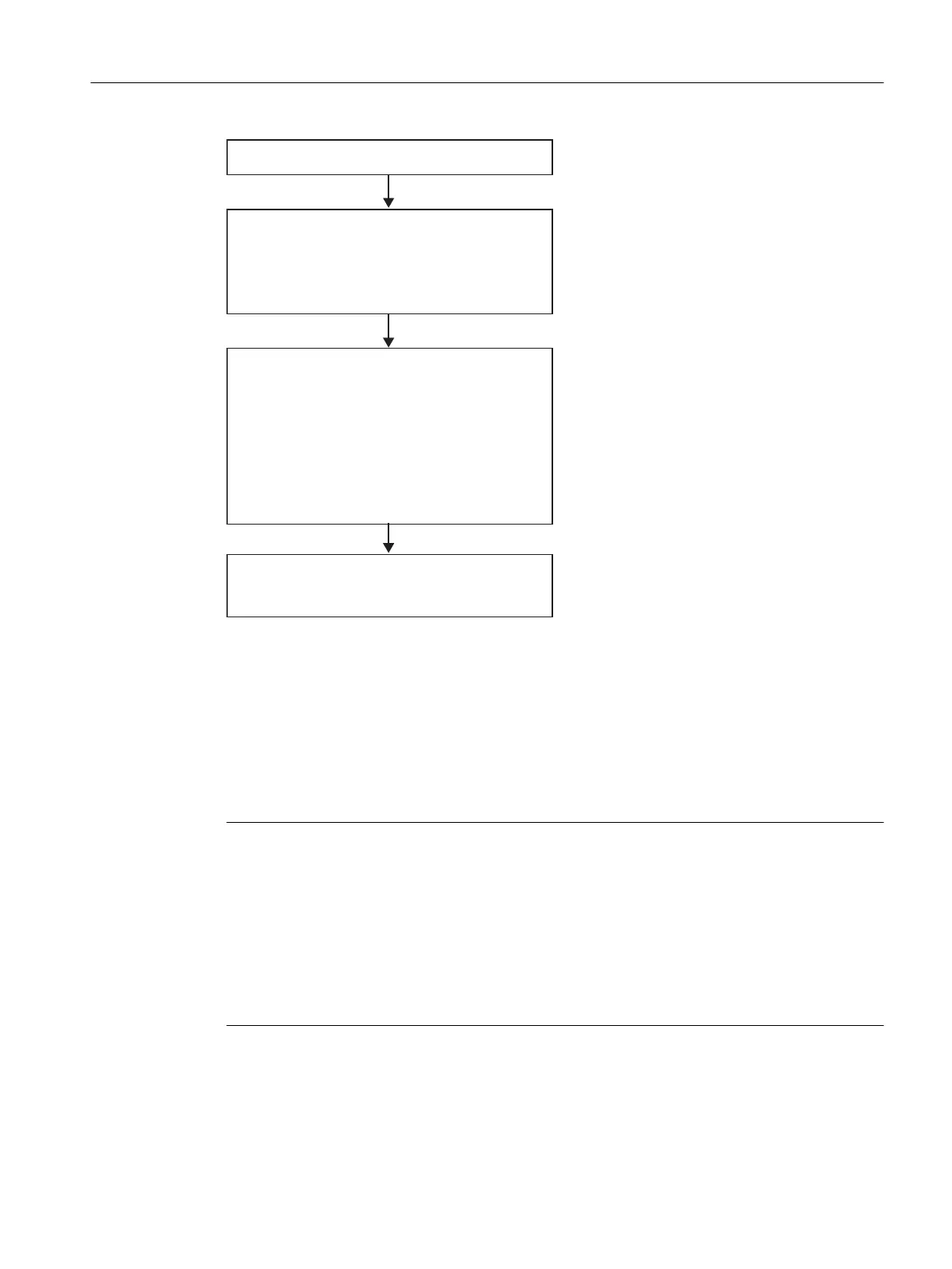

&UHDWHDQHZSURGXFWLRQRUGHU

6SHFLI\WKHSURSHUWLHVRIWKHRUGHU

ವ2UGHUQDPH

ವ7RWDOTXDQWLW\IRUWKHRUGHU

ವ(DUOLHVWVWDUWDQGODWHVWFRPSOHWLRQ

6SHFLI\SURSHUWLHVIRUHDFKEDWFK

ವ&KDQJHSUHVHWTXDQWLW\

ವ6WDUWPRGHDQGWLPHLIWLPHGULYHQ

ವReference to formula (with assigned

master recipe)

ವ,IQHFFKDQJHIRUPXODXQLWDOORFDWLRQ

ವ,IQHFFKDQJHSURFHVVLQJVHTXHQFHE\

FKDLQLQJZLWKRWKHUEDWFKHV

&KHFN

ವ7RWDOTXDQWLW\RYHUDOOEDWFKHV

ವ5XQWLPHRIHDFKLQGLYLGXDOEDWFK

Basic procedure

You create the batches for the production orders in BatchCC. By defining and selecting a

master batch, numerous batches with similar properties can be created quickly. In the

properties of each batch, you specify the reference to a released formula with assigned master

recipe or to a released master recipe without a formula category assignment. You can specify

the batch quantity and Start mode for every batch. By chaining the batches, you can define

the order in which they are processed.

Note

Excluding blocking effects with batches

Depending on the current status of the batches, the batch structure, the number of released

batches and their start mode, it is possible that batches block each other when they are running.

This effect can occur in particular when there is a failover of redundant BATCH servers or

when exiting and restarting a BATCH server.

To make sure that batches do not block each other while they are running, configure start

allocations or work with chains in the "End" mode. This is particularly important when using

synchronization functions.

Additional information

"Allocation" tab (Page 756)

BATCH Control Center

9.6 Batch Planning

SIMATIC BATCH V8.2

Operating Manual, 02/2016, A5E35958174-AA 349

Loading...

Loading...