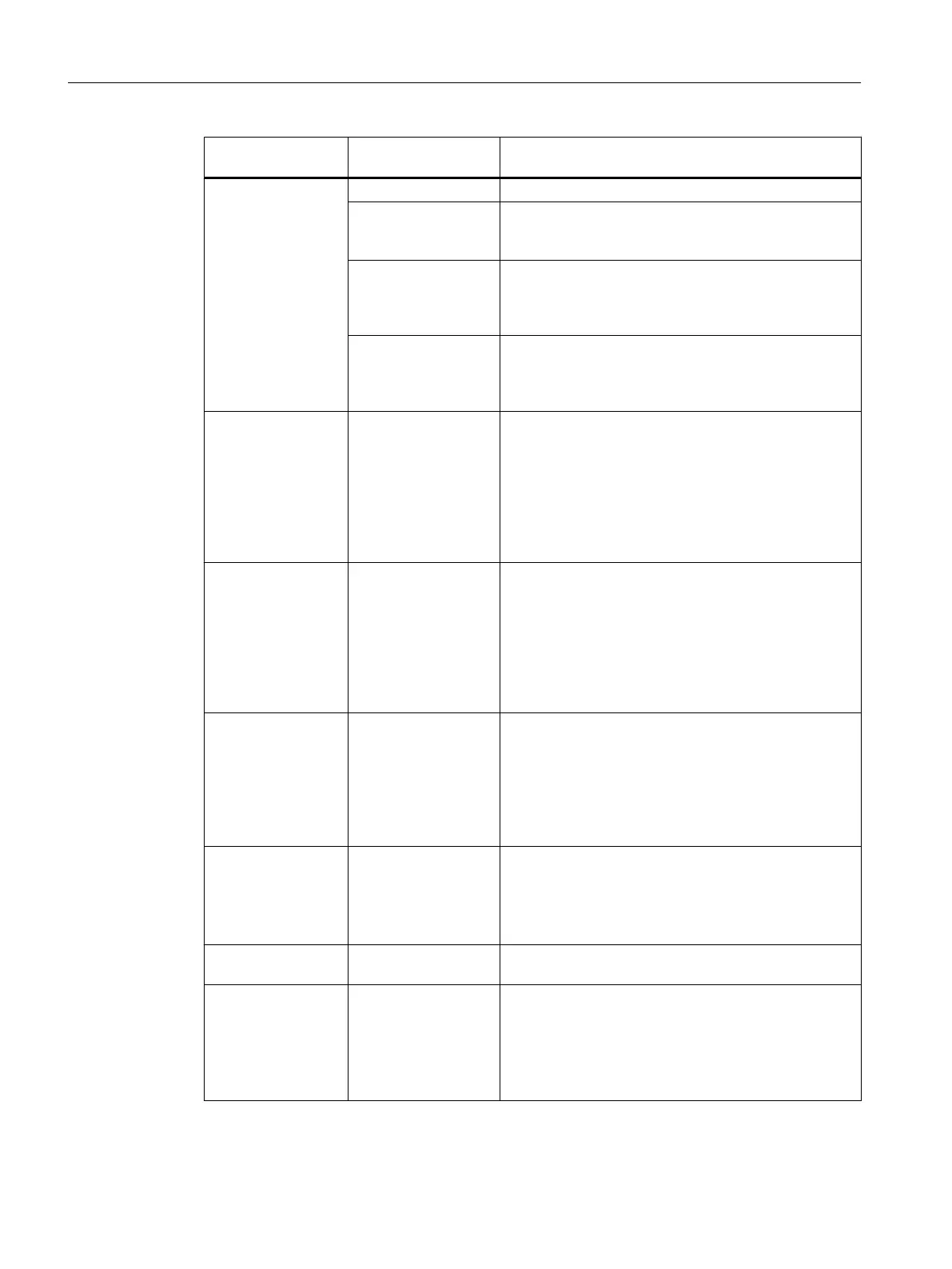

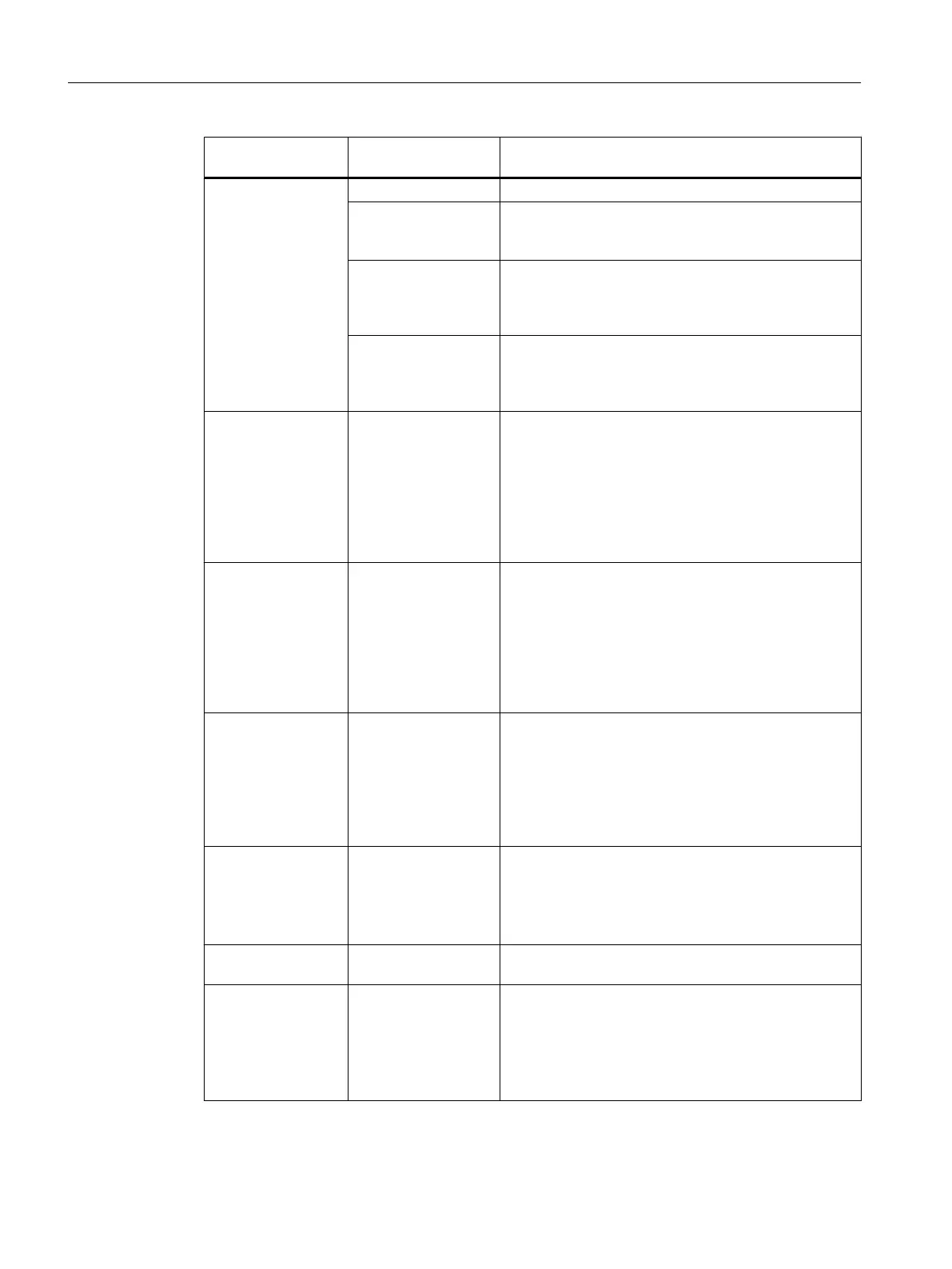

Tab What is set or dis‐

played

Meaning/comment

Product Product, Quality Settings for the main product

Product code Unique numeric code for the project (e.g. an internal

command code) with which the product can be identi‐

fied.

Reference quantity The reference quantity is meant for quantity scaling, this

means, the parameters in the recipe relate to this value

and they have to be adjusted in the event of discrepan‐

cies in the batch quantity.

Minimum scale, maxi‐

mum scale

Limits the upper and lower limits of the batch quantity.

In batch planning, the quantities specified are checked

to make sure they are not lower/higher than the values

entered here.

Input material Material list For the steps linked to EOPs, EPHs or the operator di‐

alogs, the entries are taken from the basic automation;

for a library reference from the library operation. New

materials can also be created. For each input material

configured, the material, quality, scaling function and

required quantity are specified.

Either concrete values (internal formula) or reference to

values of an external formula.

Output material Material list For the steps linked to EOPs, EPHs or the operator di‐

alogs, the entries are taken from the basic automation;

for a library reference from the library operation. New

materials can also be created. For each output material

configured, the material, quality, scaling function and

required quantity are specified.

Either concrete values (internal formula) or reference to

values of an external formula.

Parameter Parameter list For the steps linked to EOPs, EPHs or the operator di‐

alogs, the parameters are taken from the basic automa‐

tion; for a library reference from the library operation.

New parameters of the type real, bool, integer, string

and enumeration can also be created.

Either concrete values (internal formula) or reference to

values of an external formula.

Process tags Measured variables

that will be logged

Measured variables for the batch report:

You can select measured variables for archiving. As

measured variables, the process values of the parame‐

ter blocks (EPAR_) linked with the EOP, EPH and

TAG_COLL blocks are available.

Change log List of modifications List in which the modifications made to the recipe are

documented.

ESIG Electronic signature Specifying electronic signatures in compliance with

FDA or 21 CFR Part 11:

The "electronic signatures" function allows the operator

to enter one or more signatures in the form of dialogs

similar to the logon prompts normal in Windows when

operator input is made to recipes, recipe steps etc.

BATCH Recipe Editor

10.4 Creating recipes

SIMATIC BATCH V8.2

578 Operating Manual, 02/2016, A5E35958174-AA

Loading...

Loading...