2

10.04 Operation

2.13 Tools and tool offsets

2

Siemens AG, 2004. All rights reserved

SINUMERIK 840D/840Di/810D Operation/Programming ShopMill (BAS) – 10.04 Edition 2-151

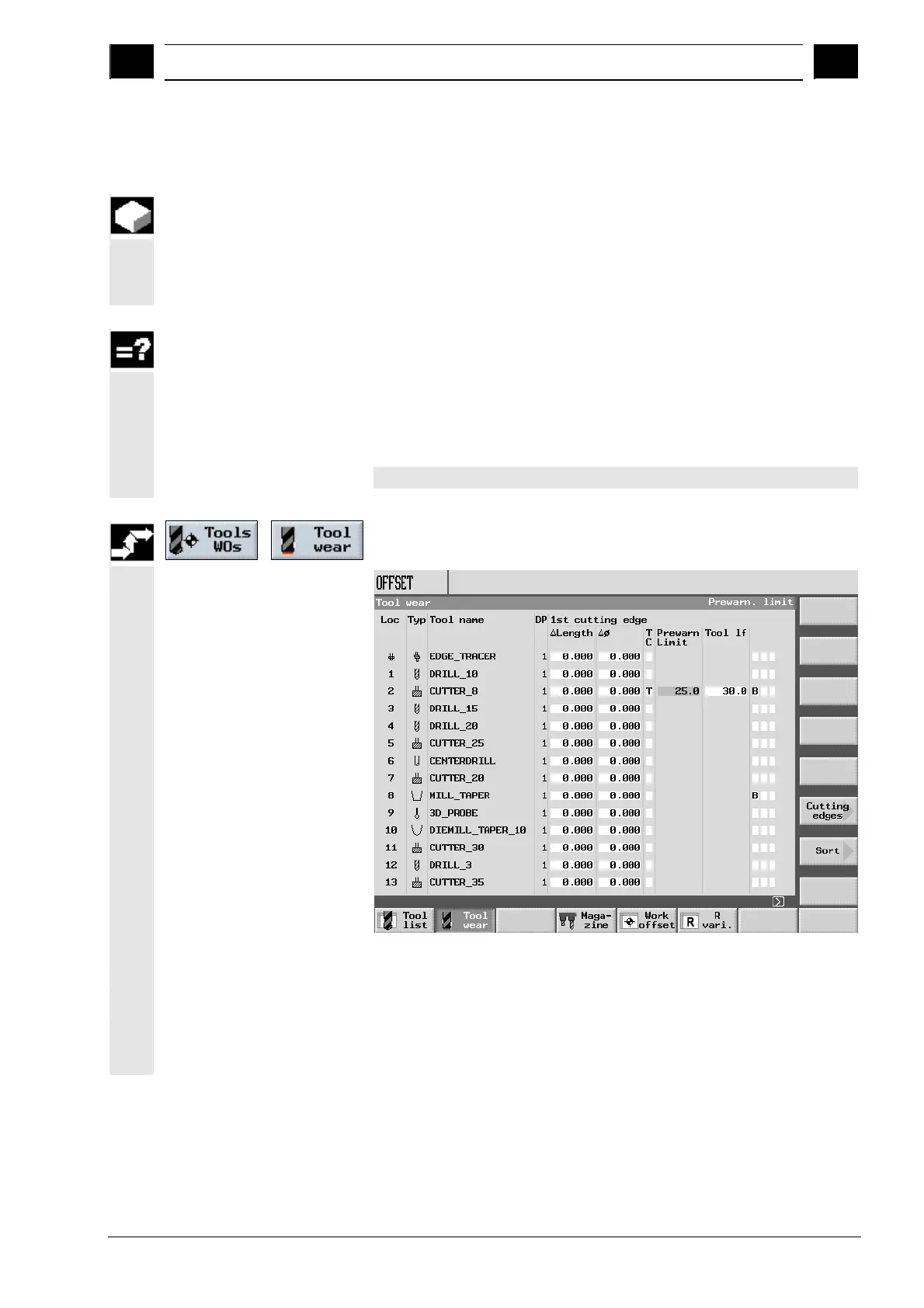

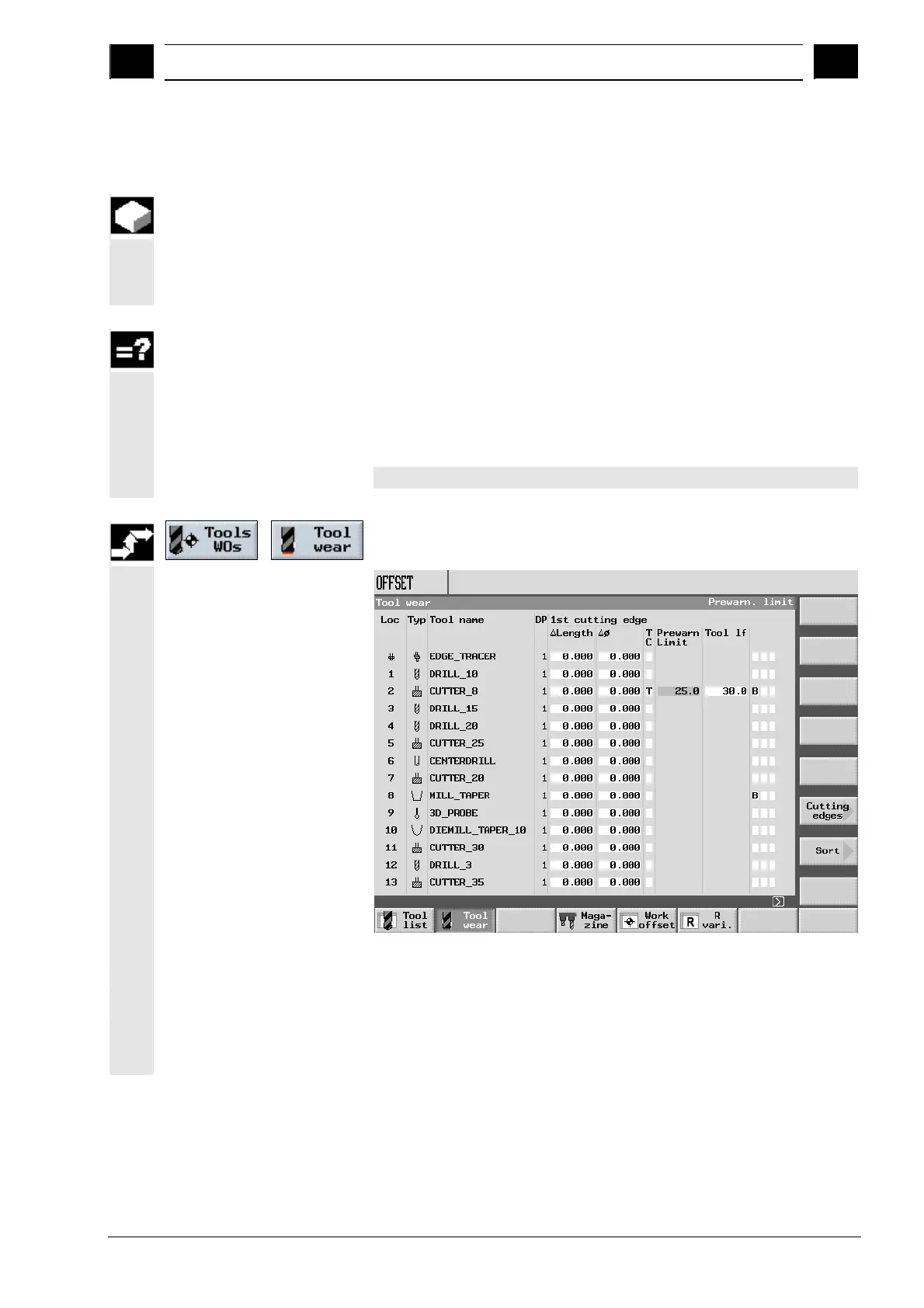

2.13.8 Entering tool wear data

Tools that are in use for long periods are subject to wear. You can

measure this wear and enter it in the tool wear list. ShopMill then

takes this information into account when calculating the tool length or

radius compensation. This ensures a consistent accuracy in

workpiece machining.

When you enter the wear data, ShopMill checks that the values do not

exceed an incremental or absolute upper limit. The incremental upper

limit indicates the maximum difference between the previous and new

wear value. The absolute upper limit indicates the maximum total

value that you can enter.

The upper limits are set in a machine data code.

Please refer to the machine manufacturer's instructions.

Select the "Tool wear" softkey in the "Tools WOs" operating area.

Example of a tool wear list with variable location allocation

Place the cursor on the tool whose wear data you want to enter.

Enter the differences for length (∆Length X, ∆Length Z) and

radius/diameter (∆Radius/∆∅) in the appropriate columns.

Loading...

Loading...