2

Operation 10.04

2.7 Measurin

a tool

2

Siemens AG, 2004. All rights reserved

2-96 SINUMERIK 840D/840Di/810D Operation/Programming ShopMill (BAS) – 10.04 Edition

Traverse the tool or spindle to the fixed point.

Jog

Select the "Measure tool" softkey in "Machine Manual" mode.

Calibrate

fixed point

Press the "Calibrate fixed point" softkey.

Enter an offset value for "DZ".

If you have used a distance gauge, enter the thickness of the plate

used.

Calibrate

Press the "Calibrate" softkey.

The distance dimensions between machine zero and fixed point is

calculated and entered in the machine data.

2.7.3 Measuring a tool with measuring probe

For automatic measurement, you determine the length and radius or

diameter of the tool with the aid of a measuring probe (table probe

system). ShopMill uses the known positions of the tool carrier

reference point and measuring probe to calculate the tool offset data.

Before you measure a tool automatically, you must enter the

approximate tool geometry data (length and radius or diameter) in the

tool list and calibrate the probe.

Depending on the setting in a machine data, you can measure the

radius or the diameter of the tool.

Please refer to the machine manufacturer's instructions.

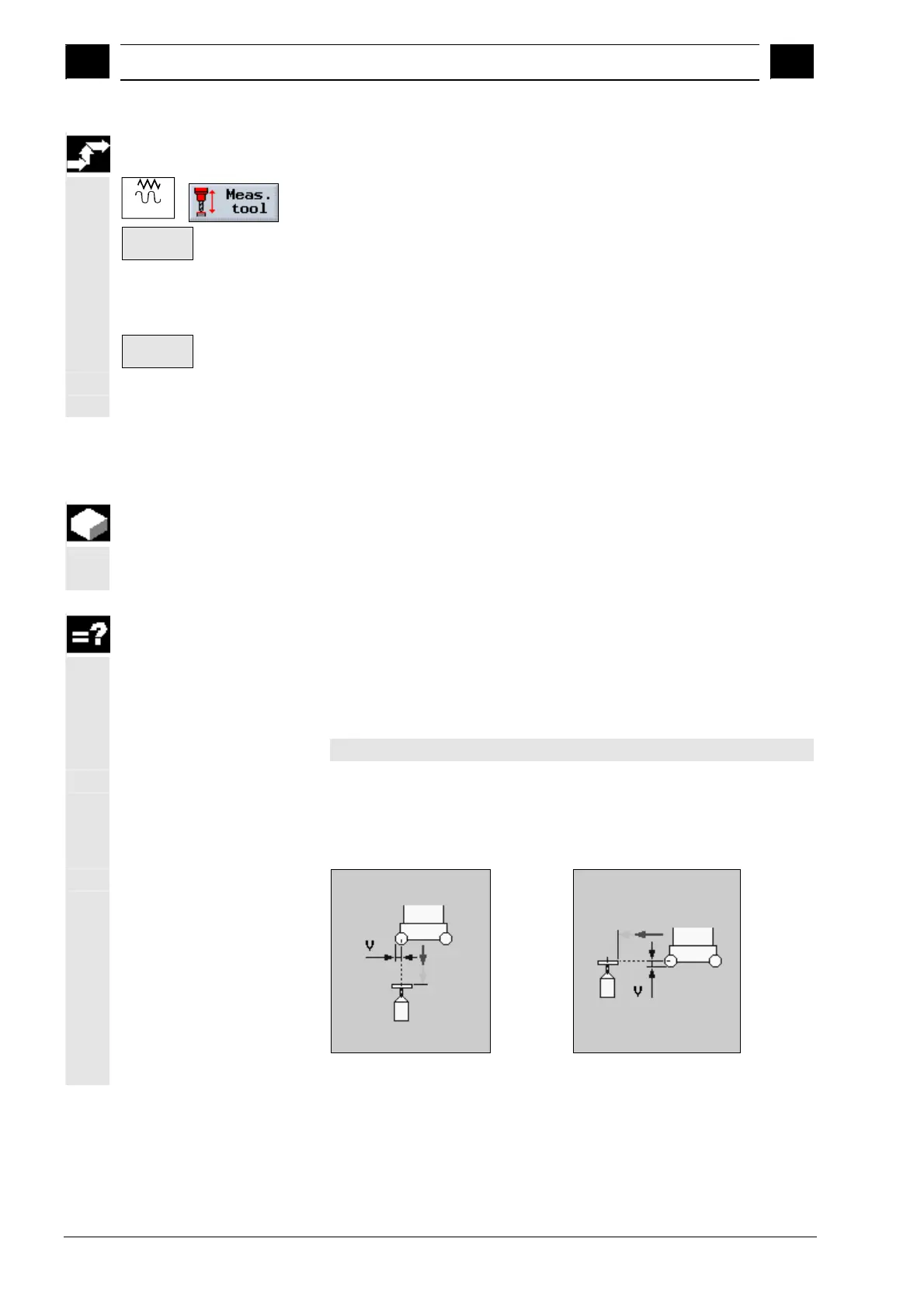

You can consider a lateral or longitudinal offset V when measuring. If

the maximum length of the tool is not at the outer edge of the tool or

the maximum width is not at bottom edge of the tool, you can store

this difference in the offset.

Lateral offset Longitudinal offset

Loading...

Loading...