3

10.04 Programming with ShopMill

3.8 Millin

3

Siemens AG, 2004. All rights reserved

SINUMERIK 840D/840Di/810D Operation/Programming ShopMill (BAS) – 10.04 Edition 3-277

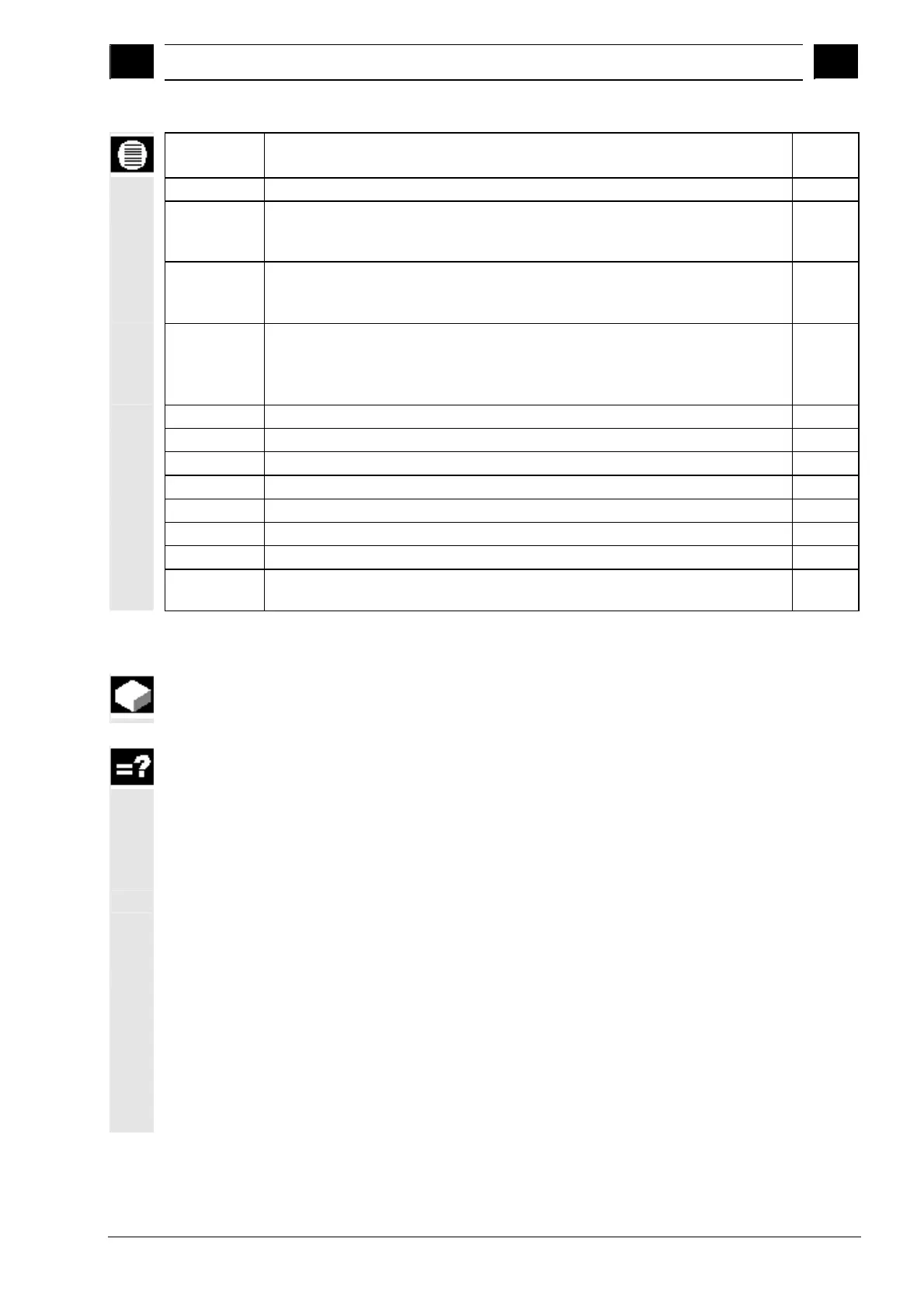

Parameters Description Unit

T, F, S, V See Sec. "Programming the tool, offset value, and spindle speed".

Machining type

Roughing

Finishing

Chamfer

Single pos.

Pos. pattern

circular spigot is machined at the programmed position (X0, Y0, Z0).

Several circular spigots are machined in a position pattern (e.g. full circle, matrix,

line).

X0

Y0

Z0

The positions refer to the reference point:

Position in X direction (single position only), abs. or inc.

Position in Y direction (single position only), abs. or inc.

Workpiece height (single position only), abs. or inc.

mm

mm

mm

∅

Diameter of spigot after machining mm

Z1 Depth of spigot (abs. or inc.) (not for chamfer) mm

FS

Chamfer width (for chamfer only), inc.

mm

ZFS

Insertion depth tool tip (for chamfer only), abs. or inc.

mm

DZ Max. depth infeed (Z direction) (not for chamfer) mm

UXY Finishing allowance in plane (spigot diameter) (not for chamfer) mm

ZU Finishing allowance depth (spigot base) (not for chamfer) mm

∅1

Diameter of blank spigot

(important for determining approach position)

mm

3.8.6 Longitudinal slot

Use the "Longitudinal slot" function if you want to mill any kind of

longitudinal slot.

The following machining methods are available:

• Mill longitudinal slot from solid material.

• Predrill longitudinal slot in the center first if, for example, the

milling cutter does not cut across center (program the drilling,

rectangular pocket and position program blocks one after

another).

Depending on the dimensions of the longitudinal slot in the workpiece

drawing, you can select a corresponding reference point for the

longitudinal slot.

Approach/retraction

1. The tool moves at rapid traverse to the retraction plane and

infeeds at safety clearance.

2. The tool is inserted into the material according to the chosen

strategy.

3. The longitudinal slot is always machined with the chosen

machining type from inside out.

4. The tool moves back to the safety clearance at rapid traverse.

Loading...

Loading...