8

Alarms and Messages 10.04

8.1 C

cle alarms and messa

es

8

Siemens AG, 2004. All rights reserved

8-398 SINUMERIK 840D/840Di/810D Operation/Programming ShopMill (BAS) – 10.04 Edition

8.1 Cycle alarms and messages

8.1.1 Error handling in the cycles

If error conditions are detected in the cycles, an alarm is output and

processing is aborted.

Alarms with numbers between 61000 and 62999 are output in the

cycles.

The reset criteria for these number ranges are

• 61000 ... 61999 is NC-RESET

• 62000 ... 62999 is CANCEL

The text displayed with the alarm number provides an explanation of

the cause of the error.

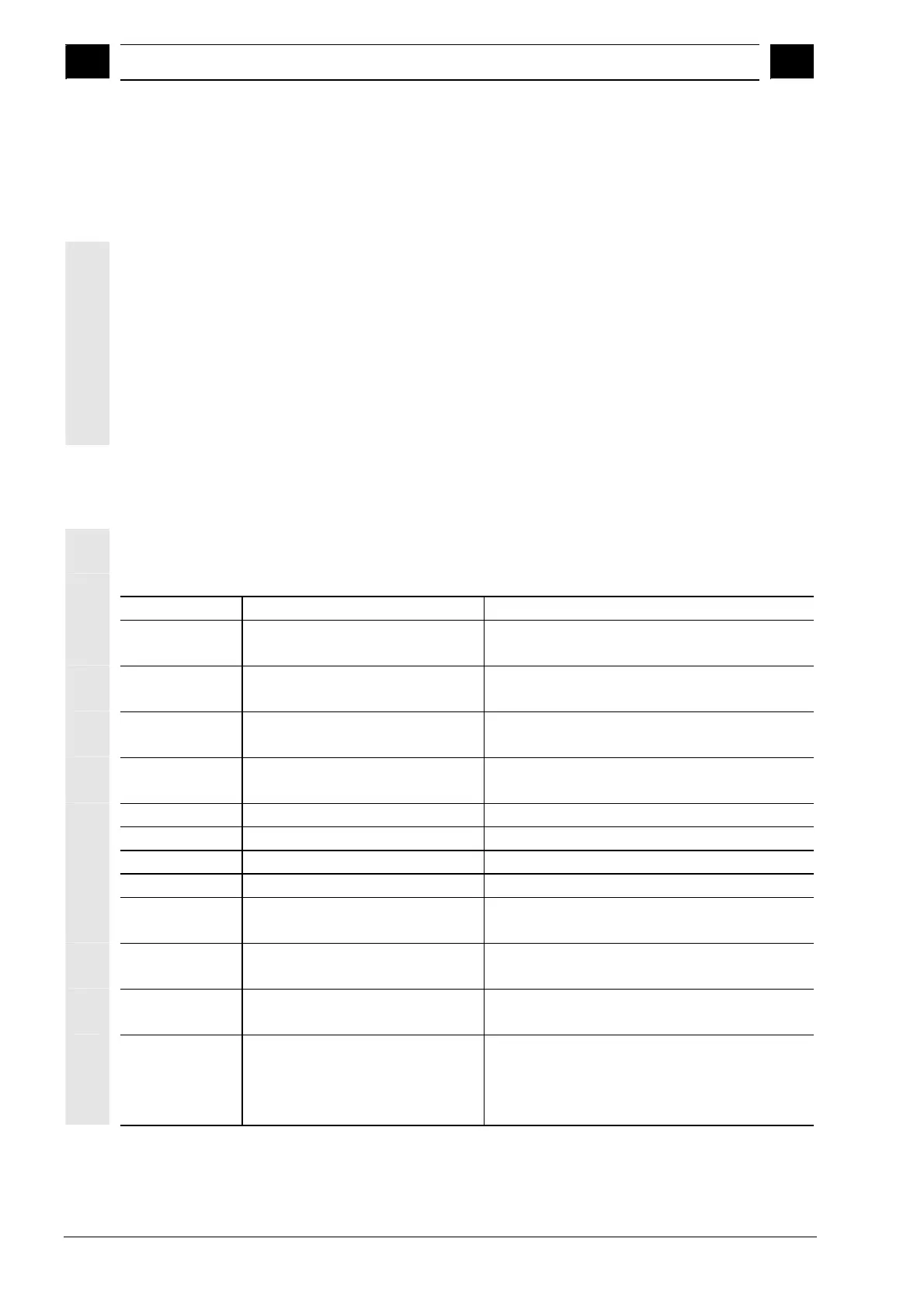

8.1.2 Overview of cycle alarms

The following table lists the alarms that might occur in the cycles with tips on how

to remedy the errors that cause them.

Alarm number Alarm text Explanation, remedy

61000 "No tool offset active" D-correction must be programmed before the

cycle call

61001 "Thread pitch incorrectly defined" Check parameters for thread size and check

pitch information (contradict each other)

61002 "Machining type incorrectly

defined"

The machining type parameter has been set to

the wrong value and needs to be altered.

61003 "No feedrate programmed in cycle"The parameter for feedrate has been incorrectly

set and must be altered.

61006 "Tool radius too large" Select smaller tool

61007 "Tool radius too small" Select larger tool

61009 "Active tool number = 0" Load the required tool

61010 "Finishing allowance too large" Reduce the finishing allowance setting

61011 "Invalid scaling" The active scaling factor is not permissible for

this cycle.

61012 "Different scales in one plane" Cycle execution only possible with uniform

scaling in the plane

61013 "Basic settings have been altered,

program cannot be executed"

Check and, if necessary, change the basic

settings

61101 "Reference plane incorrectly

defined"

Either different values must be entered for the

reference plane and the retraction plane if they

are relative values or an absolute value must

be entered for the depth

Loading...

Loading...