2

Operation 10.04

2.6 Measurin

work

iece zero

2

Siemens AG, 2004. All rights reserved

2-90 SINUMERIK 840D/840Di/810D Operation/Programming ShopMill (BAS) – 10.04 Edition

Positioning a rotary axis

and entering a feedrate

Once you have measured the workpiece zero you must reposition the

rotary axis.

The activation window asking whether you want to "Position rotary

axis X to align?" is displayed.

Select "Yes" if you want to position the rotary axis.

An input field for the feedrate and the softkey "Rapid traverse" are

displayed.

Rapid

traverse

Press the "Rapid traverse" softkey to enter the feedrate in rapid

traverse.

- OR -

Enter the desired offset in input field "F".

Cycle Start

Press the "Cycle Start" key.

The rotary axis is repositioned.

2.6.7 Calibrating an electronic measuring tool

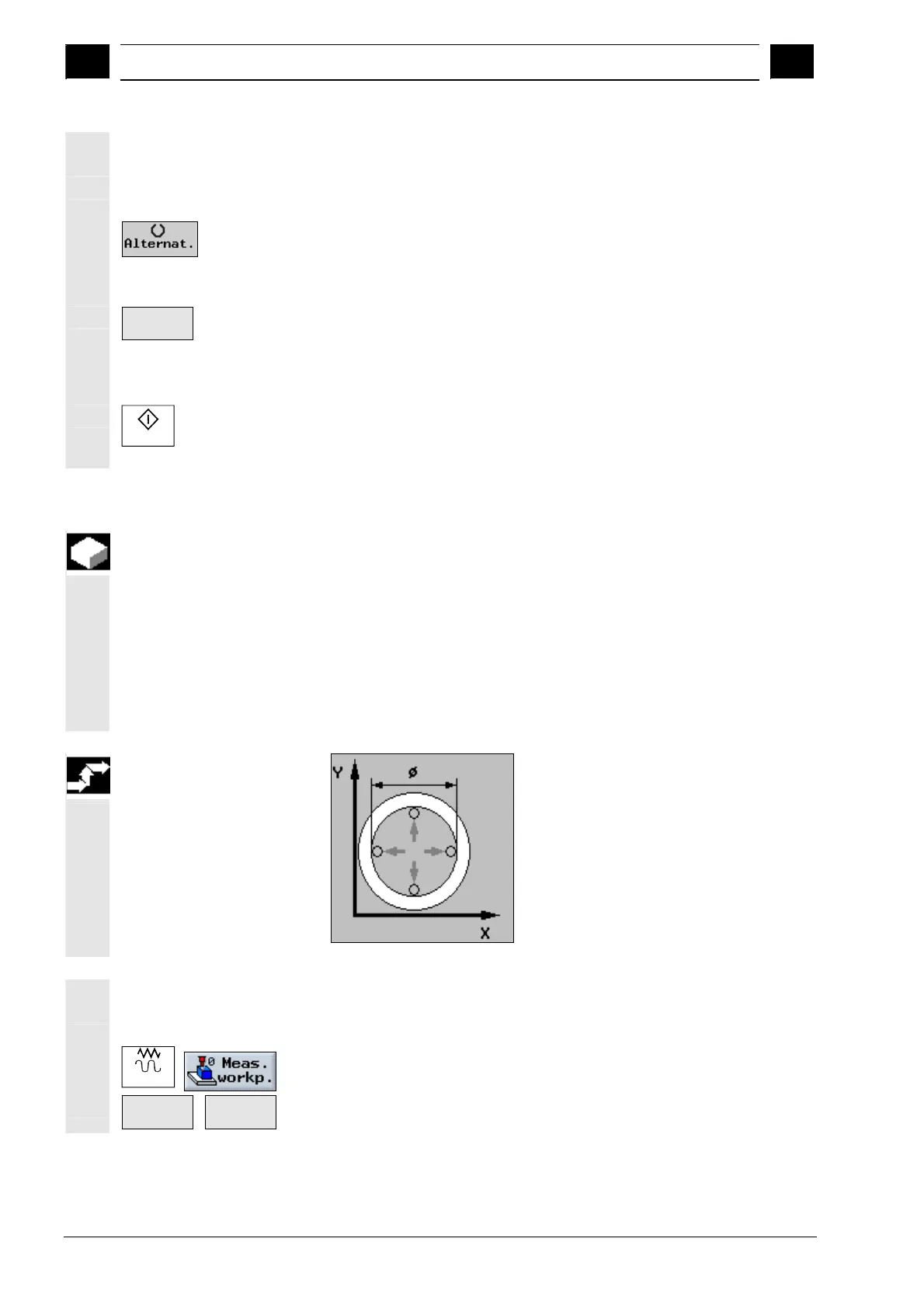

When the electronic measuring tools are attached to the spindle,

clamping tolerances often occur. This can lead to measurement

errors.

In addition, you need to determine the trigger point of the measuring

tool relative to the spindle center (trigger point).

Therefore, you need to calibrate the electronic measuring tool. The

radius is calibrated in a hole, the length is calibrated on a surface. For

the hole, you can use a hole in the workpiece or use a ring gauge.

The radius of the measuring tool must be contained in the tool list.

Calibrating a radius

1. Attach a 3D probe type tool to the spindle.

2. Move the tool into the hole and position it in the approximate

center of the hole.

Jog

3. In "Machine Manual" mode, select the "Meas. workp." softkey.

Calibration

probe

Radius

4. Press the "Calibration probe" and "Radius" softkeys.

Loading...

Loading...