Detailed Description

2.5 Programming

Spindles (S1)

2-60 Function Manual, 08/2005 Edition, 6FC5397-0BP10-0BA0

2.5 2.5 Programming

2.5.1 Programming in the part program

Programming statements

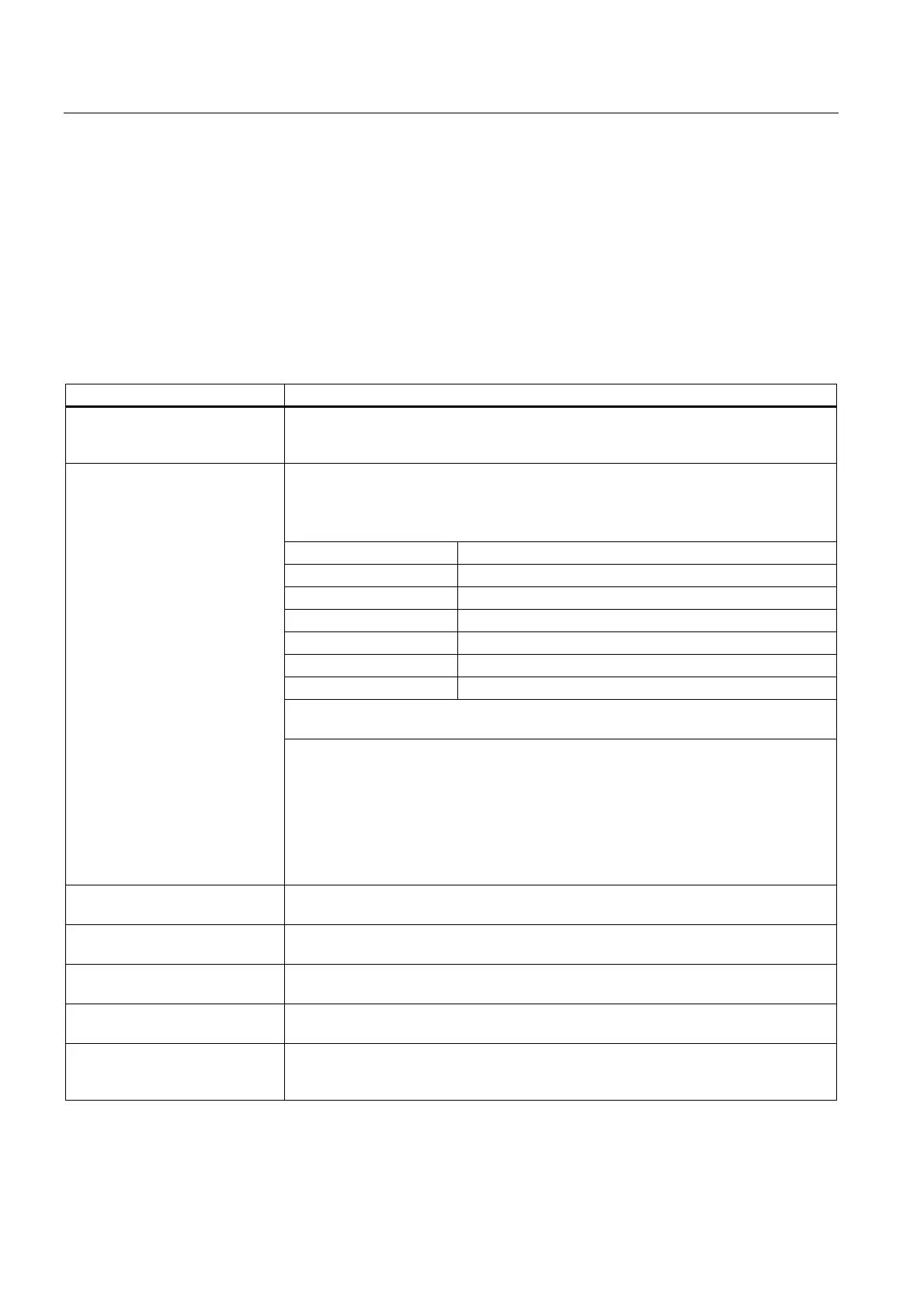

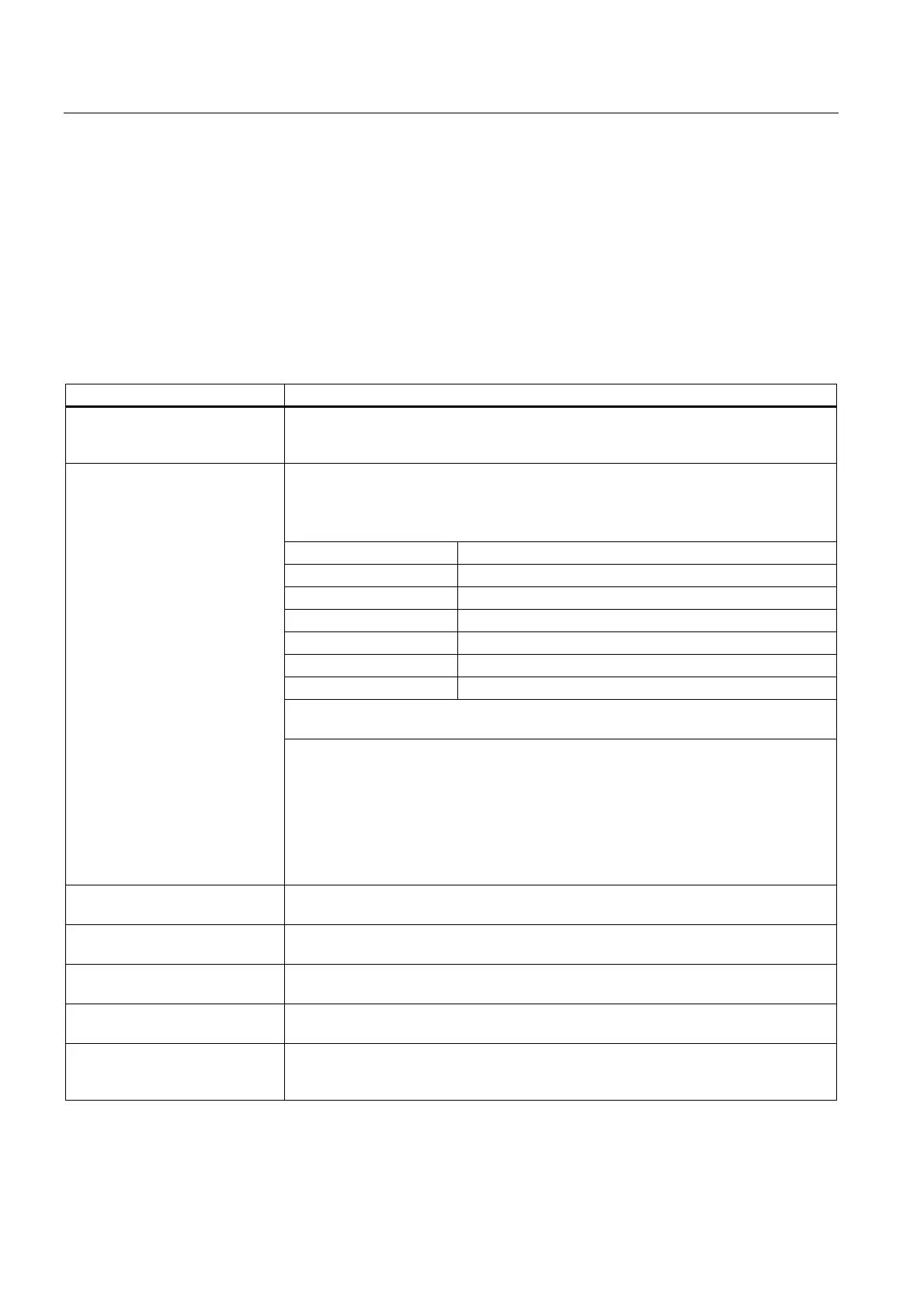

Statement Description

SETMS The master spindle is the spindle stored in machine data:

MD20090 $MC_SPIND_DEF_MASTER_SPIND

(initial setting for master spindle on channel).

The spindle with the number (n) is the master spindle

(can differ from the initial setting in machine data:

MD20090 $MC_SPIND_DEF_MASTER_SPIND).

The master spindle must be defined for the following functions:

G95

Rev. feedrate

G96 S../G961 S... Constant cutting speed in m/min or ft/min

G97/G971

Cancel G96/G961 and freeze last spindle speed

G63

Tapping with compensating chuck

G33/G34/G35

Thread cutting

G331/G332

Rigid tapping

G4 S... Dwell time in spindle revolutions

Programming M3, M4, M5, S, SPOS, M19, SPOSA, M40, M41 to M45 and WAITS without

entering the spindle number.

SETMS(n)

The current master spindle setting can be retained via RESET and START.

The setting is made in machine data:

MD20110 $MC_RESET_MODE_MASK

and

MD20112 $MC_START_MODE_MASK.

References:

/FB1/Descriptions of Functions, Basic Machine;

Mode Group, Channel, Program Operation (K1)

M3

M1=3

Direction of spindle rotation clockwise for master spindle.

Direction of spindle rotation clockwise for spindle number 1

M4

M2=4

Direction of spindle rotation counterclockwise for master spindle.

Direction of spindle rotation counterclockwise for spindle number 2

M5

M1=5

Spindle stop without orientation for master spindle.

Spindle stop without orientation for spindle number 1

S ....

S2= ....

Spindle speed in rpm for master spindle.

Spindle speed in rpm for spindle number 2

SPOS =270

SPOS[n] =270

Spindle positioning for the master spindle or

the spindle with number n to the position 270 degrees.

The block change is only performed when the spindle is in position.

Loading...

Loading...