Detailed Description

2.1 Motion monitoring functions

Axis Monitoring, Protection Zones (A3)

2-2 Function Manual, 08/2005 Edition, 6FC5397-0BP10-0BA0

2.1.2 Following Error Monitoring

Function

In control engineering terms, traversing along a machine axis always produces a certain

following error, i.e. a difference between the set and actual position.

The following error that arises depends on:

• Position control loop gain

MD32200 $MA_POSCTRL_GAIN (servo gain factor)

• Maximum acceleration

MD32300 $MA_MAX_AX_ACCEL (Maximum axis acceleration)

• Maximum velocity

MD32000 $MA_MAX_AX_VELO (Maximum axis velocity).

• With activated feedforward control: Precision of the path model and the parameters:

MD32610 $MA_VELO_FFW_WEIGHT

(Factor for the velocity feedforward control)

MD32800 $MA_EQUIV_CURRCTRL_TIME

(Equivalent time constant current control loop for feedforward control)

MD32810 $MA_EQUIV_SPEEDCTRL_TIME

(Equivalent time constant speed control loop for feedforward control)

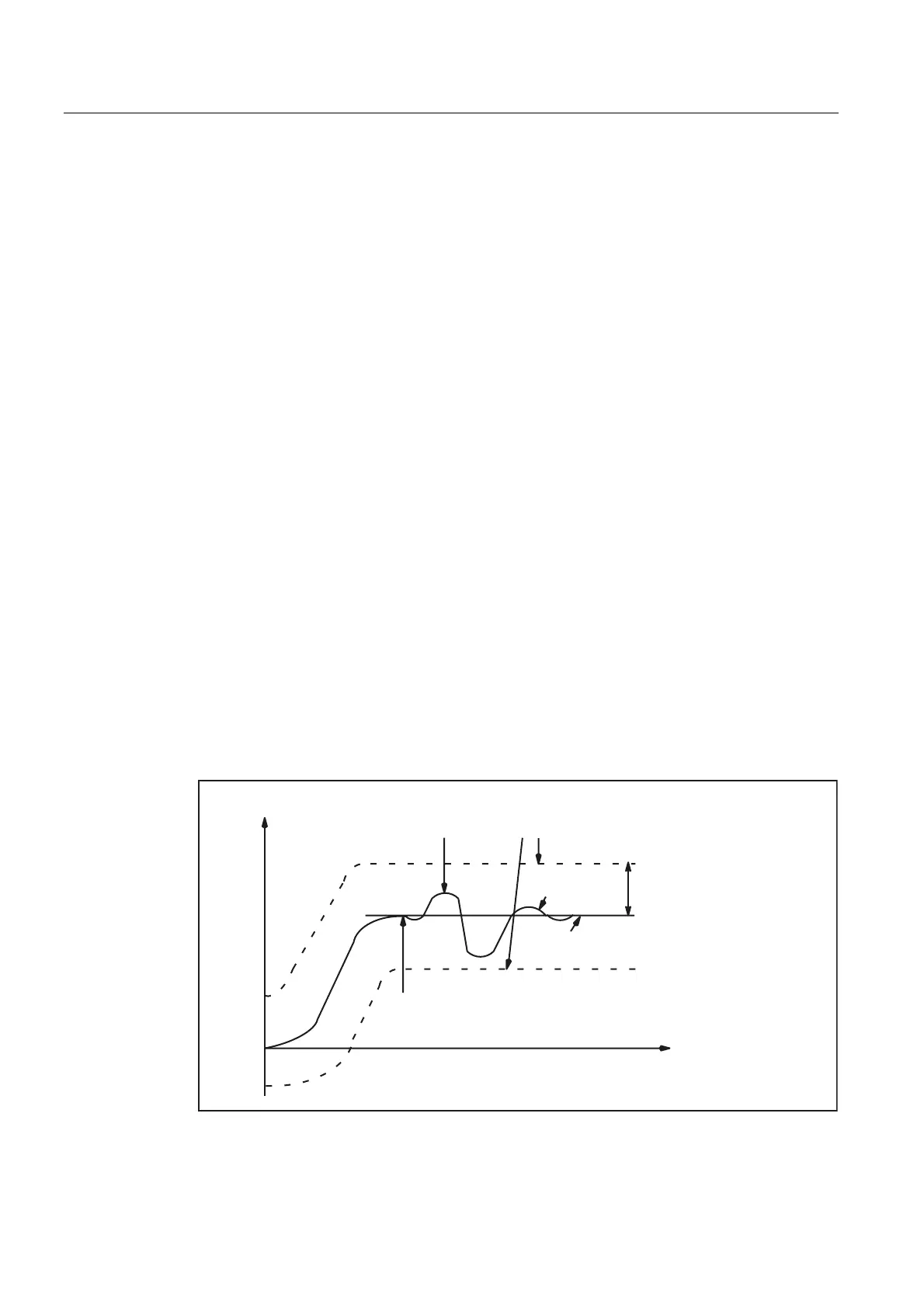

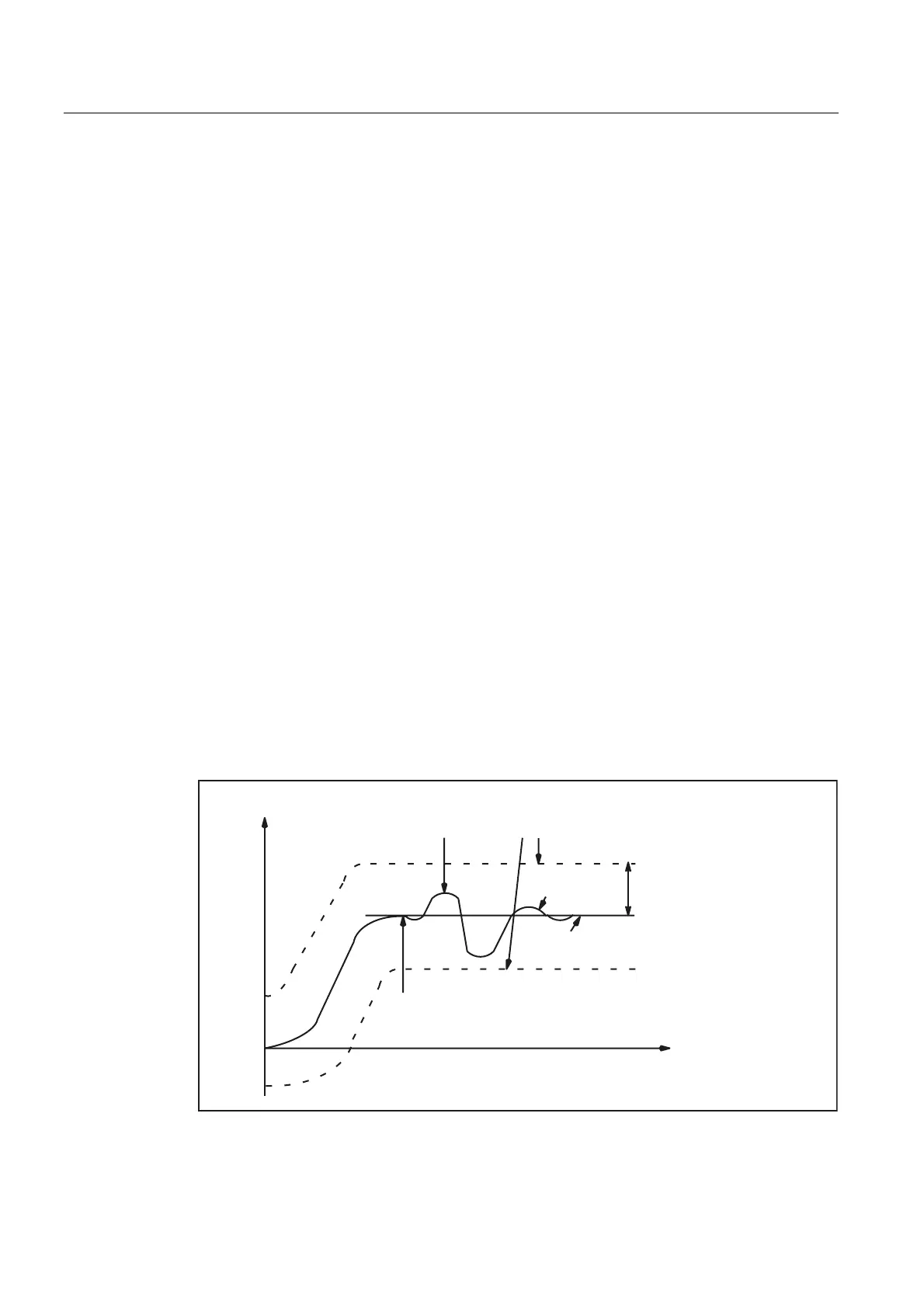

In the acceleration phase, the following error initially increases when traversing along a

machine axis. After a time depending on the parameterization of the position control loop,

the following error then remains constant in the ideal case. Due to external influences, more

or less large fluctuations in the following error always arise during a machining process. To

prevent these fluctuations in the following error from triggering an alarm, a tolerance range

within which the following error may change must be defined for the following error

monitoring:

MD36400 $MA_CONTOUR_TOL (Contour monitoring tolerance range)

'V

W

)ROORZLQJHUURU

)LUVWFXW

0'&217285B72/

0HDVXUHG

IROORZLQJHUURU

6WDUWRI

PDFKLQLQJ

7ROHUDQFHEDQG

&DOFXODWHG

IROORZLQJHUURUPRGHO

Fig. 2-1 Following Error Monitoring

Loading...

Loading...